JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 19

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION/SHUT-DOWN

Shutting Down the Rebar Bender and Power Unit

1. Remove Rebar Bender from the rebar.

2. Place ON/OFF toggle switch in the OFF position.

3. Unplug AC Power cord from receptacle.

4. Disconnect hydraulic hose from Power Unit.

5. Place protective hose cap on the male coupler end of

the hose.

6. Roll up hydraulic hose. Store Rebar Bender in a safe

place.

7. On the Power Unit, wrap the power and remote cords

neatly. Store Power Unit in safe place.

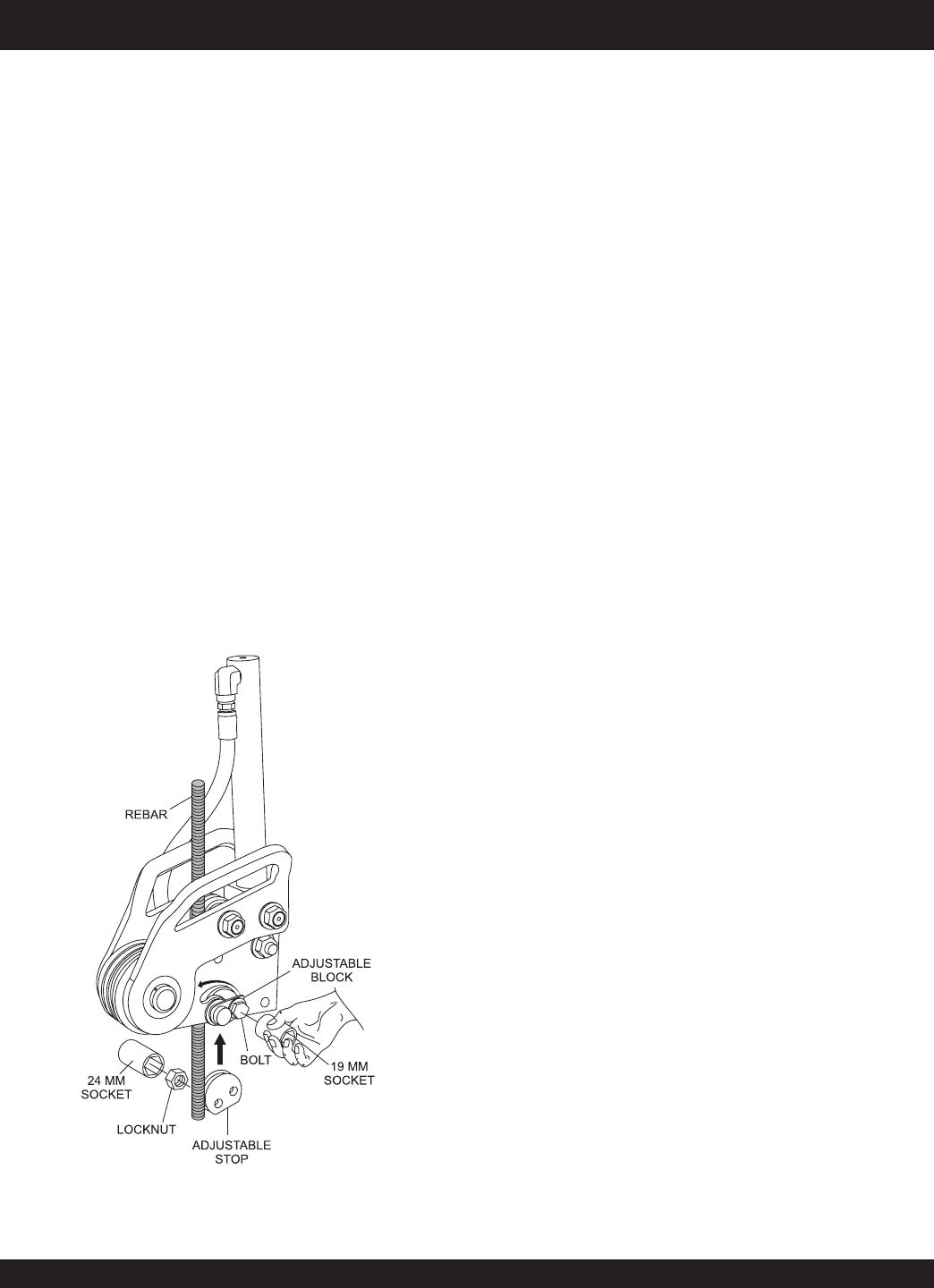

Rebar Adjustment Bolt

For Model JB5090, JB7090, JB8090

The rebar bender may require adjustment in order to obtain a

90° bend. Adjustment is necessary due to inconsistencies in the

rebar produced by steel mills and because each bender is

capable of handling multiple diameters of rebar.

1. Use a 19 MM socket to loosen the bolt and a 24 MM

socket to loosen the locknut (Figure 17) until the adjust-

able block can be slid easily in the crescent groove on

the side of the rebar. Note: there is no need to remove the

hardware.

2. Insert a piece of the rebar to be used into the machine

to assist in positioning the adjustable stop.

3. Slide the adjustable stop towards the rebar (away from

the hydraulic ram) until it makes contact with the rod.

4. Back the adjustable stop off the rebar slightly so the rod

can pass easily through the machine without binding.

5. Tighten the hardware securely , connect the bender to

the pump and make a test bend. You should now be able

to attain the desired bending angle. If the desired bend is

not attained, repeat the process until the desired result

is achieved.

Figure 17. Rebar Adjustment Bolt