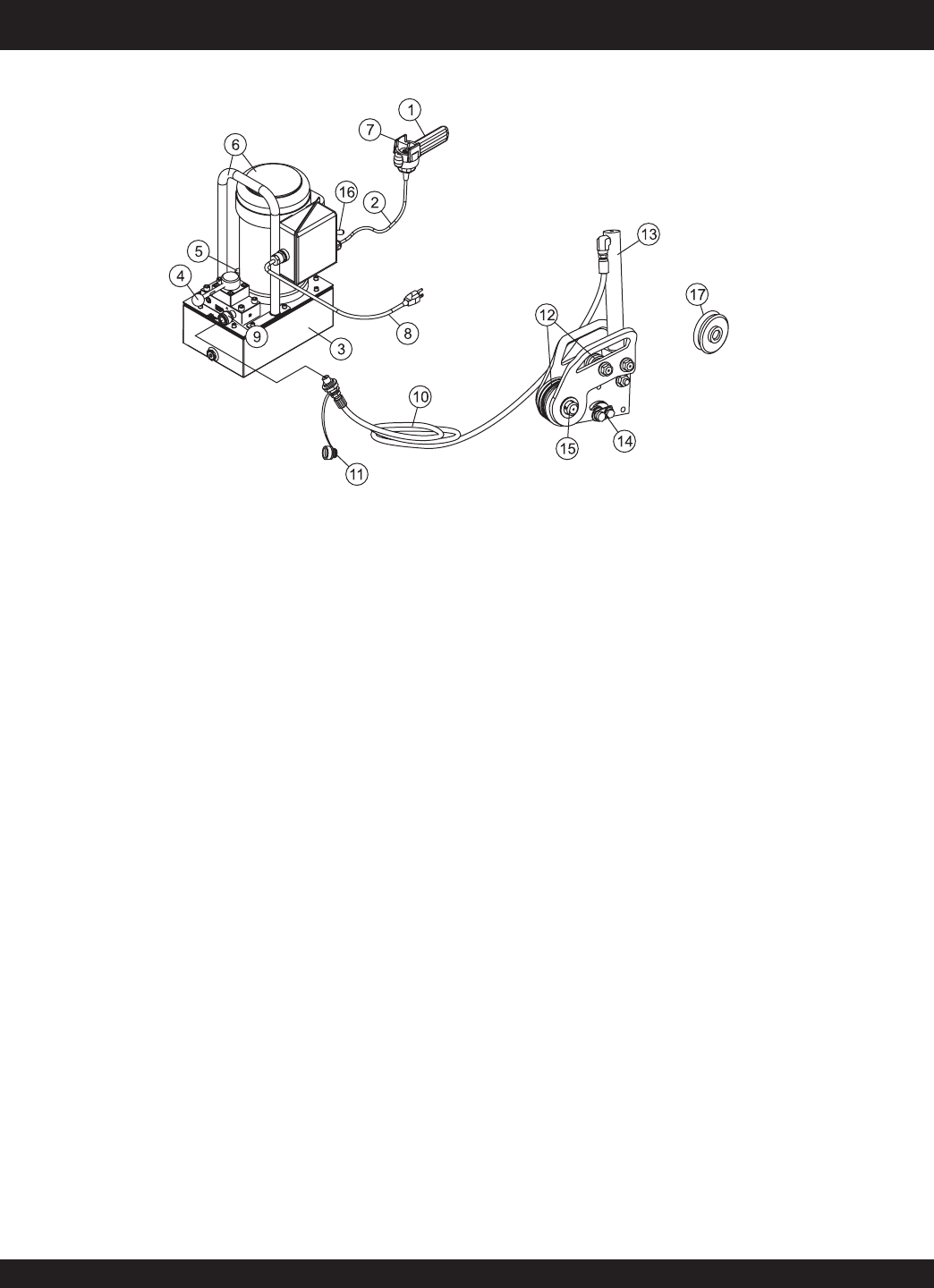

JIMMY SERIES HYDRAULIC REBAR BENDERS — OPERATION AND PARTS MANUAL — REV. #9 (01/04/08) — PAGE 13

1. Remote Control Unit – Allows the hydraulic cylinder

on the rebar unit to be

advanced

or

held

.

2. Remote Control Cable – Allows the Electric-Hydraulic

Pump to be operated remotely.

3. Hydraulic Reservoir– Holds 1.00 gallon (3.78 liters)

of hydraulic oil. Fill only with recommended type

hydraulic oil.

4. Pump Control Lever – Move this lever to actuate the

hydraulic cylinder on the rebar bender. The lever allows

the cylinder to be

advanced

,

held

or

returned.

5. Hydraulic Oil Fill Cap – Remove this cap to add

hydraulic fluid to the reservoir. Fill with commercial

hydraulic oil.

6. Electric-Hydraulic Pump/Carrying Handle – When

transporting of the pump is required, always use the

carrying handle or lifting bale to lift the unit.

7. Electric-Hydraulic Pump ON/OFF Switch – Move the

toggle switch to the forward position to activate the

electric motor. The electric motor will stay on as long

as the switch is held. Release the switch to turn off the

electric motor.

8. AC Power Cord – Plug this 10 ft. (3.0 meters) power

cord into a 115 VAC grounded type receptacle. NEVER

remove the ground pin from the plug. This will defeat

the ground circuit and greatly increase the possibility

of electrical shock.

9. Female Quick Disconnect Fitting – Connects to the

hydraulic hose and allows for easy removal.

10. Hydraulic Hose (Rebar Bender) – Connect one end

of this hose to the female quick disconnect fitting on

the electric-hydraulic pump, connect the other end (90°

fitting) to the hydraulic input port on the rebar bender

cylinder.

11. Hose Cap – When the rebar bender is not in use,

ALWAYS cover the hose’s male fitting with this cap.

This will prevent dirt and foreign matter from entering

the cylinder cavity.

12. Main and Upper Arm Rollers – Always keep large

and small rollers clean and lubricated to insure smooth

rolling. Remove any dirt or debris that may have

accumulated on the rollers during operation.

13. Hydraulic Cylinder – When actuated can apply a force

between 2~10 tons (2,032 ~10,160 kg.)

14. Rebar Adjustment Bolt – There is an adjustment bolt

on the side plate of the rebar bender. Adjust these bolts

to accommodate different size rebar.

15. Main Roller Shaft – To remove the large roller (main)

or stuck rebar from the unit, push the roller shaft inward

to release. Some units have a pin-clip mechanism for

the removal of the main roller. See Figure 14.

16. Electric Motor On/Off Switch – When placed in the

ON position, supplies 115VAC, 60Hz power to the

electric motor.

17. Straightening Roller – Accessory roller for

straightening rebar. For use with JB5090, JB7090,

JB8090 only.

Figure 6. Jimmy Hydraulic Rebar Bender Components

JIMMY SERIES HYDRAULIC REBAR BENDERS — COMPONENTS