- 85 -

Piping connection

Please follow the following procedures, during the piping connection work is carried out. If the procedures are

not followed properly, the refrigerant and valve sheet might gush out from the ball valve. It might cause the injury.

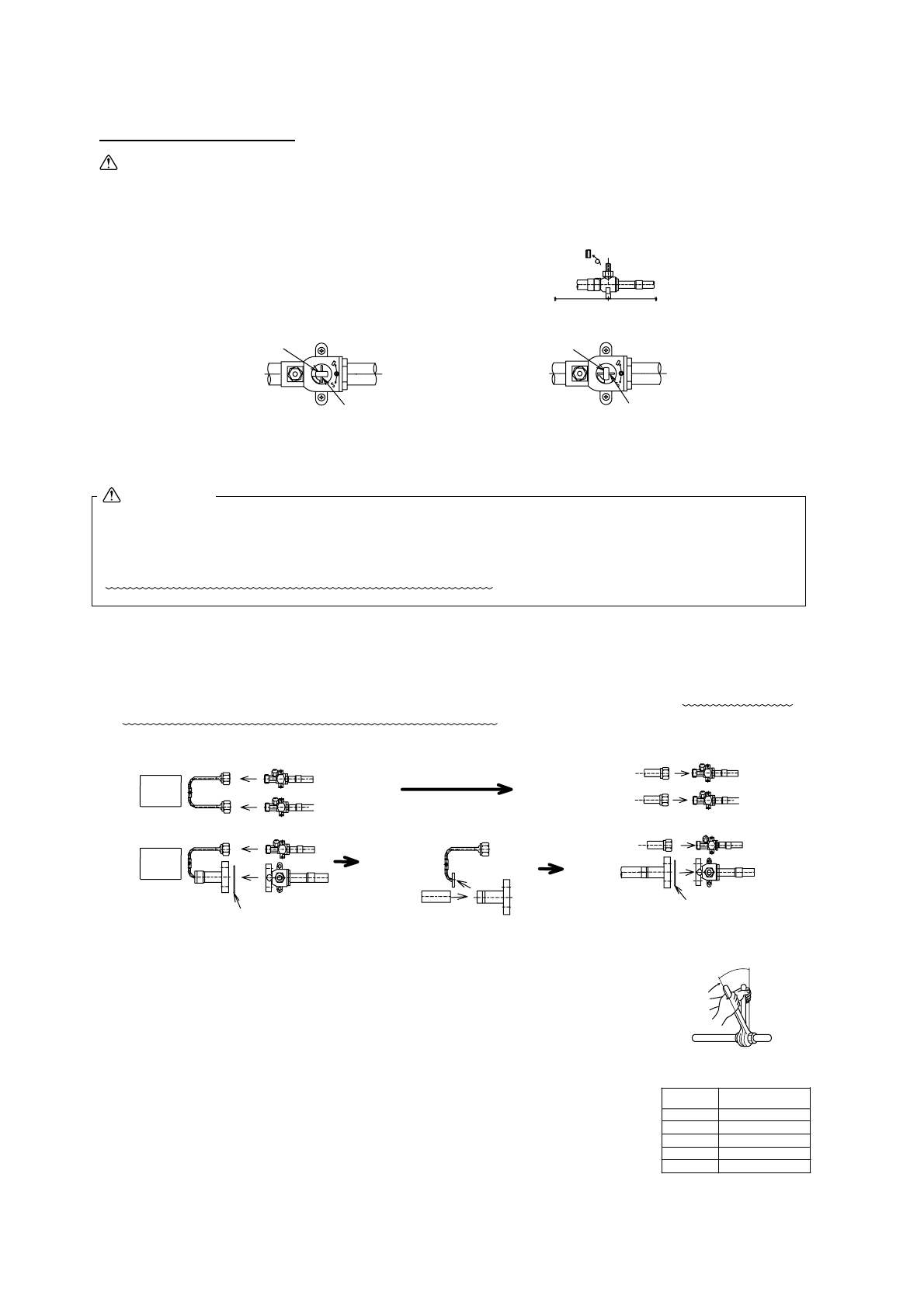

1. PROCEDURE TO CONNECT THE EXTENSION PIPE

Proceed with the connection as follows.

(1) Open the ball valve cap at first. (Fig. 1)

(2) Check the ball valve section is completely closed. (Fig. 2)

2. HANDLING PRECAUTIONS

(1) The extension pipes should be connected under closing condition. (Fig. 2)

Do leak test the part of flange and flare.

(2) Before charging the refrigerant, vacuum the extension pipes and indoor side to clear all

the air and water.

(3) Charge the additional amount of refrigerant according to the installation manual.

(4) Do leak test again.

(5) Turn the ball valve knob to “Open” position. (Fig. 3)

(6) Finally, put the cap back to the ball valve.

(3) Remove the connection pipe assy. (Fig. 4)

Throw away the packing. (Except the PUH-5)

(4) Remove the by-pass tube. (Except the PUH-5) (Fig. 5)

Braze the extension pipe with the flange assy. (Except the PUH-5)

(5) Connect the extension pipes with the ball valves (the flare nut type).

(Only the PUH-5) (Fig. 6)

Connect the extension pipes with the ball valves (the flare nut and the flange type). (Fig. 6) Use the attached

new packing certainly between the ball valve and the flange.

There will be small amount of refrigerant gushed out of the by-pass tube at the moment. Loosen and tighten the

flare nut using a double-ended wrench. (Fig. 7 and Table. 1)

Coat the flare contact surface and both surface of packing with refrigerator oil.

Do not brazing work before removing the connection pipe assy. (Except the PUH-5)

Fig. 1

Fig. 2

Valve knob

Close

Fig. 3

Valve knob

Open

Pin

Pin

Packing (throw away)

Flange assy

Extension pipe

Extension pipe

use the attached new packing

By-pass tube

Unit side

Unit side

Connection Pipe assy

Unit side

Unit side

Extension pipe

Fig. 5

Fig. 4

Fig. 6

Fig. 7

Connection Pipe assy

PUH-5

PU(H)

8-20

pipe diameter

(Nm) / (kgcm)

(mm)

Tightening torque

6.35

14 to 18 / 140 to 180

9.52

35 to 42 / 350 to 420

12.7

50 to 57.5 / 500 to 575

15.88

75 to 80 / 750 to 800

19.05

100 to 140/1000 to1400

Table. 1

Warning

Caution: