–90–

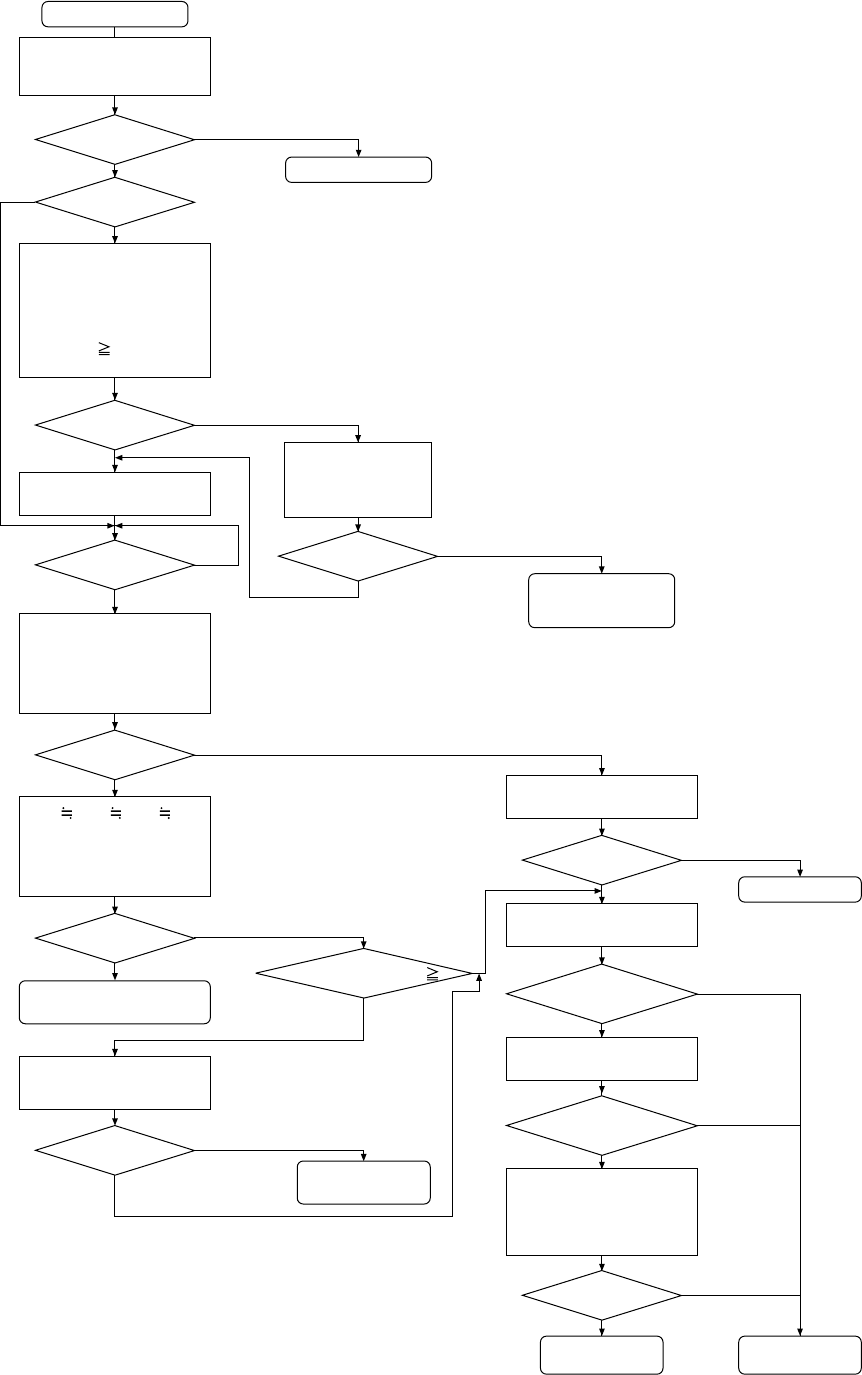

(4) Troubleshooting the major components of the BC controller

1) Pressure sensor

Pressure sensor troubleshooting flow

Check on the LED monitor dis-

play.

• TH2 or LPS of outdoor unit.

• HPS of outdoor unit

• PS1, PS3 of BC controller and

confirm the following relationship

HPS > PS1

PS3 > TH2 or LPS

(puressure calculated value)

Check that refrigerant pip-

ing and transmission line

connections are in agree-

ment between outdoor

unit and BC controller.

START

Check pressure sensor, PS1,

PS3, connectors for discon-

nection, looseness, or incor-

rect attachment.

OK?

Stop the unit (compres-

sor OFF).

At least

10 minutes passed since

stopping?

Check PS1, PS3 on LED

monitor display and confirm

that none of the detected

pressure values is below

1kg/cm

2

G (0.098MPa).

OK?

OK?

OK?

OK?

Change board.

Repair faulty connection.

Change pres-

sure sensor.

OK?

Replace the wrong

puressure sensor with the

correct pressure sensor, and

confirm It’s detected pres-

sure is indicated correctly.

Short connectors 2 and 3 on the

board and check the pressure.

Pressure

range within 0 to 1kg/cm

2

G

(0.098MPa)

Pressure

of at least 32kg/cm

2

G

(3.14MPa) indicated?

Remove the pressure sensor

connector from the board, and

check the pressure.

Check for faulty connector on

applicable pressure sensor.

Correct refrigerant

piping and trans-

mission line.

OK?

OK?

Note 3

Take corrective action.

HPS PS1 PS3 TH2

or LPS (pressure calcu-

lated value) (The differ-

ence is less than

1kg/

cm

2

G (0.098MPa)

No board or pressure

sensor abnormality.

Check that refrigerant piping and

transmission line connections are

in agreement between outdoor

unit and BC controller.

Confirm the

following relationship PS1

PS3?

Correct refrigerant

piping and the trans-

mission line.

Unit running?

Note 1

No

Note 2

No

No

Note 2

No

No

No

Ye s

No

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

No

Note 4

No

No

No

Yes

Yes

Yes

No

No

Ye s