7

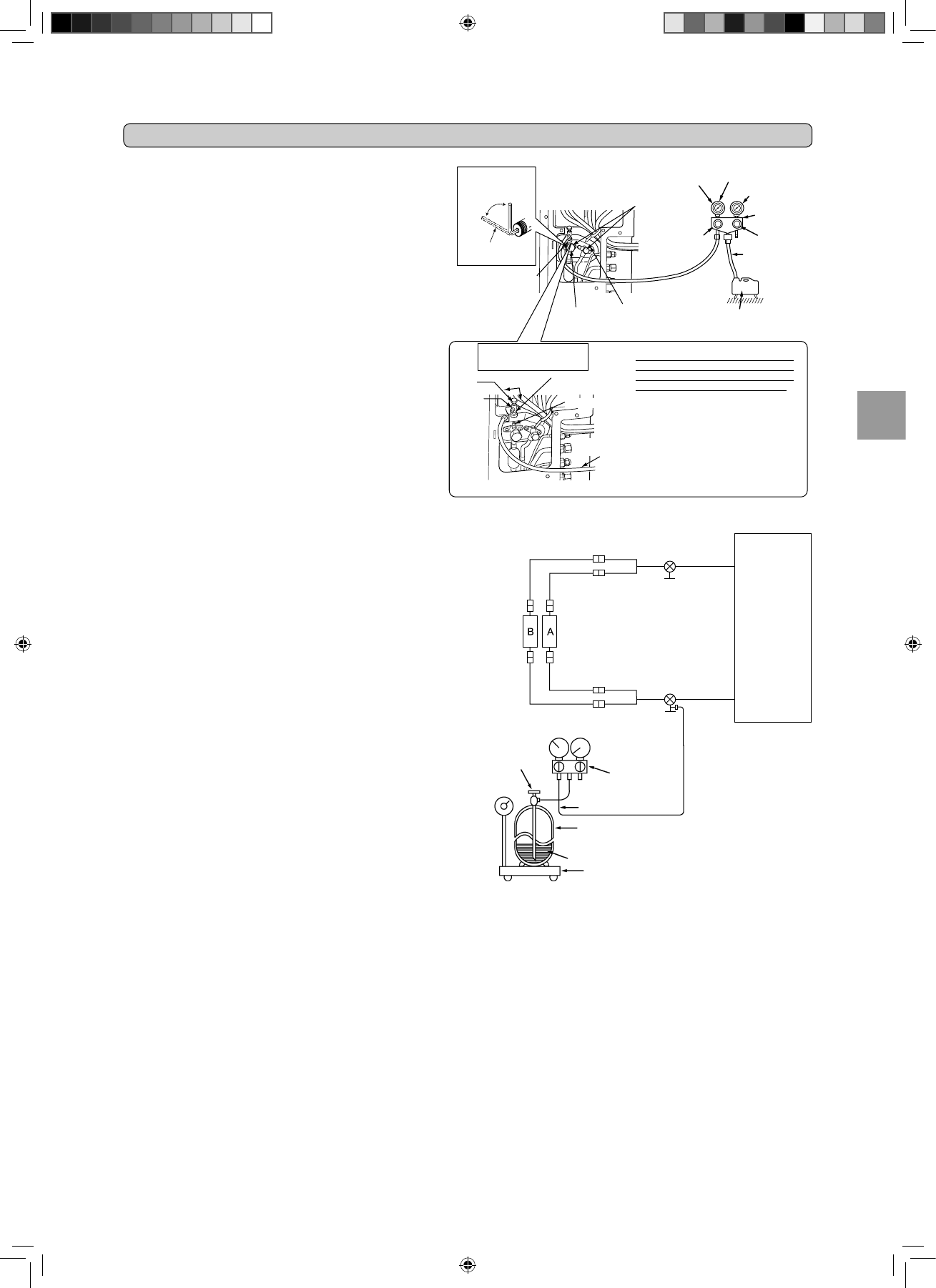

4-1.PURGINGPROCEDURESANDLEAKTEST

Stop valve

for GAS

Stop valve cap

(Torque 19.6 to

29.4 N•m, 200 to

300 kgf•cm, 15 to

22 ft

•lb)

Gauge manifold

valve(forR410A)

Compound pressure

gauge(forR410A)

–0.101MPa

[–760 mmHg

(-30in.Hg)]

Handle

Low

Handle High

Vacuum pump

(forR410A)

*Close

*Open

Hexagonal wrench

*4 to 5 turns

Stop valve

for LIQUID

4. PURGINGPROCEDURES,LEAKTEST,ANDTESTRUN

Pressure gauge

(forR410A)

Precautions when using

the control valve

When attaching the control valve to

theserviceport,valvecoremayde-

form or loosen if excess pressure is

applied.Thismaycausegasleak.

Service port

Charge hose

(forR410A)

Body

Close

Open

Control

valve

A

When attaching the control valve to

the service port, make sure that the

valve core is in closed position, and

then tighten part A. Do not tighten

partAorturnthebodywhenvalve

core is in open position.

4-2.GASCHARGE

Perform gas charge to unit.

1 Connectgascylindertotheserviceportofstopvalve.

2 Performairpurgeofthepipe(orhose)comingfromrefrigerantgas

cylinder.

3 Replenishspeciedamountoftherefrigerant,whileoperatingtheair

conditioner for cooling.

Note:

Incaseofaddingrefrigerant,complywiththequantityspeciedforthe

refrigeratingcycle.

CAUTION:

Whenchargingtherefrigerantsystemwithadditionalrefrigerant,besure

touseliquidrefrigerant.Addinggasrefrigerantmaychangethecomposi

-

tionoftherefrigerantinthesystemandaffectnormaloperationoftheair

conditioner.Also,chargethesystemslowly,otherwisethecompressor

will be locked.

Tomaintainthehighpressureofthegascylinder,warmthegascylinder

withwarmwater[under40°C(140°F)]duringcoldseason.Butneveruse

nakedreorsteam.

Union

Stop valve

Liquid pipe

Union

Union

Union

Indoor

unit

Stop valve with

service port

Gas pipe

Refrigerant gas

cylinder

operating valve

(forR410A)

Gauge manifold

valve(forR410A)

Chargehose(forR410A)

Refrigerantgascylinder

for R410A with siphon

Electronic scale for

refrigerant charging

Refrigerant(liquid)

Outdoor

unit

1)Removeserviceportcapofstopvalveonthesideoftheoutdoorunit

gas pipe. (The stop valve will not work in its initial state fresh out of

thefactory,totallyclosedwithcapon.)

2)Connectgaugemanifoldvalveandvacuumpumptoserviceportof

stop valve on the gas pipe side of the outdoor unit.

3)Runthevacuumpump.(Vacuumizeformorethan15minutes.)

4)Checkthevacuumwithgaugemanifoldvalve,thenclosegauge

manifold valve, and stop the vacuum pump.

5)Leaveasitisforoneortwominutes.Makesurepointergaugemani

-

foldvalveremainsinthesameposition.Conrmthatpressuregauge

shows–0.101MPa[Gauge][–760mmHg(-30in.Hg)].

6)Removegaugemanifoldvalvequicklyfromserviceportofstop

valve.

7)Afterrefrigerantpipesareconnectedandevacuated,fullyopenall

stop valves on both sides of gas pipe and liquid pipe. Operating with

-

outfullyopeninglowerstheperformanceandthiscausestrouble.

8)Referto1-4.,andchargetheprescribedamountofrefrigerantif

needed.Besuretochargeslowlywithliquidrefrigerant.Otherwise,

compositionoftherefrigerantinthesystemmaybechangedandaf

-

fect performance of the air conditioner.

9)Tightencapofserviceporttoobtaintheinitialstatus.

10)Leaktest

Service port cap

(Torque 13.7 to

17.7 N•m, 140 to

180 kgf

•cm, 10 to

13 ft

•lb)

Charge hose

(forR410A)

JG79A039H01_En.indd 7 5/9/2008 2:23:44 PM