Installation plate (1)

Center of

ø 3 in.

(75 mm)

hole

8-11/16 in.

(220 mm)

or more

4-11/16 in.

(120 mm)

or more

2-13/16 in. (70 mm) or more

5-1/8 in. (130 mm) or more for left

and left back piping (using spacer)

Ceiling

Wall

Wall

Attachment screw (2)

* Same for left hole.

Insert

the

scale. *

Align the

scale with

the line. *

Level

• Make ground wire a little longer than

others. (More than 1-9/16 in. [40 mm])

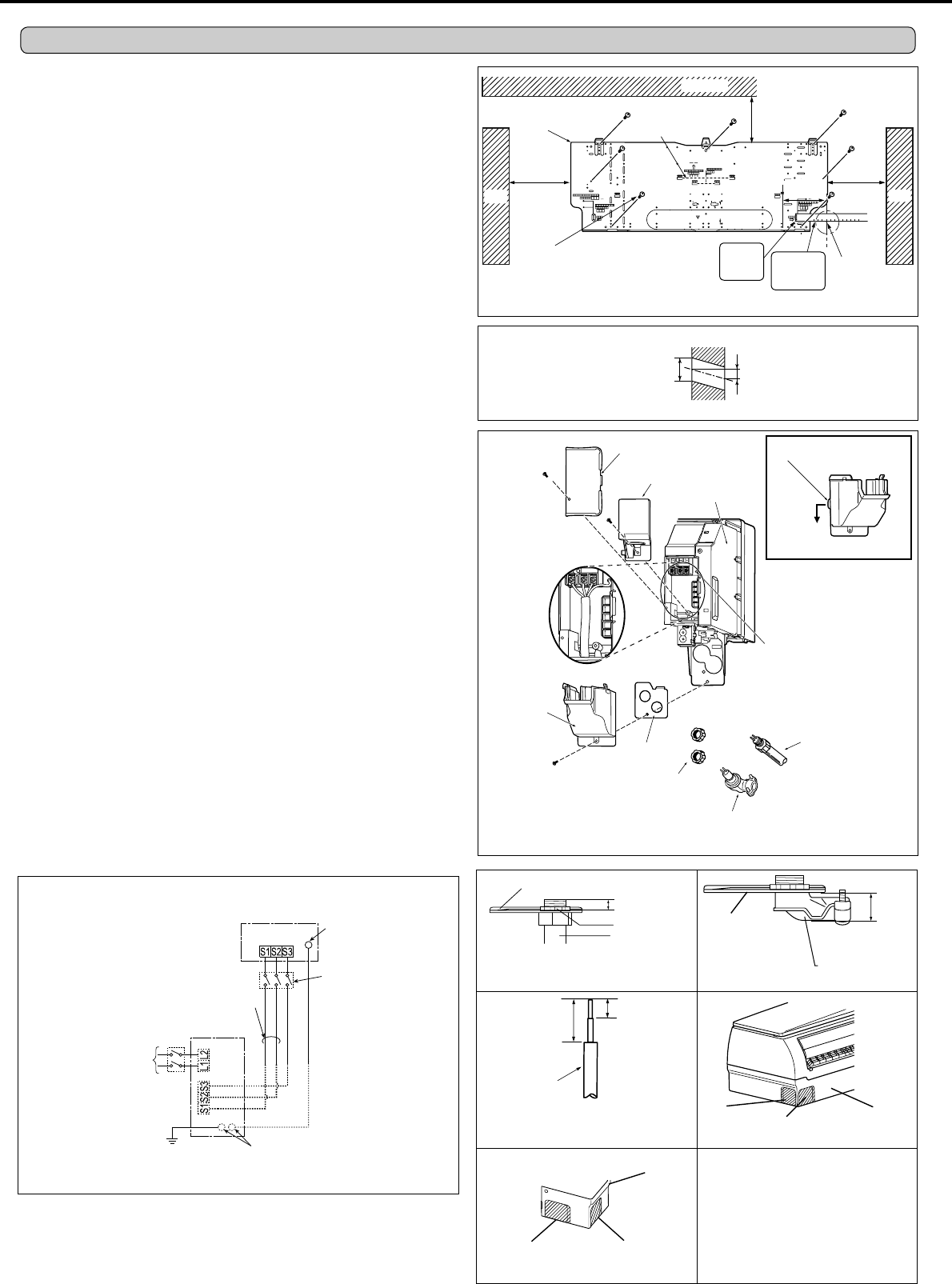

2-1. ATTACHING THE INSTALLATION PLATE

• Find a stud in the wall to attach installation plate (1) horizontally on the wall with screws (2).

• To prevent installation plate (1) from vibrating, be sure to install the attachment screws

in the holes indicated in the illustration. For added support, additional screws may also

be installed in other holes.

,IWKHUHFHVVHGEROWLVWRRORQJFKDQJHLWIRUDVKRUWHURQH¿HOGVXSSOLHG

2. INDOOR UNIT INSTALLATION

Wall

Outdoor side

2-2. DRILLING

1) Determine where the holes will be located on the wall.

2) Drill a ø 3 in. (75 mm) hole. The outdoor side should be 6/32 to 9/32 in. (5 to 7 mm)

lower than the indoor side.

3) Insert wall hole sleeve (C).

2-3. CONNECTING WIRES FOR INDOOR UNIT

Note:

When the indoor unit is powered from the outdoor unit, depending on local code, a discon-

nect switch needs to be installed to a power supply circuit.

1) Open the front panel.

2) Place the upper part of the indoor unit on the installation plate.

3) Remove electrical cover.

4) Remove VA clamp.

5) Remove corner box.

6) Remove cable guide.

7) Remove conduit plate.

8) Attach conduit pipe (for rear piping) / elbow joint (for right, left, or downward piping) to

conduit plate with lock nut. The thread of the installed conduit pipe / elbow joint appear-

ing inside should be less than 3/8 in. (10 mm). (Fig. 1) Elbow joint should appear less

than 1-3/16 in. (30 mm) outside. (Fig. 2)

9) Process the end of ground wire (Fig. 3). Connect it to the ground terminal of electrical

parts box.

10) Process the end of indoor/outdoor unit connecting wire (A) (Fig.3). Attach it to the

terminal block. Be careful not to make mis-wiring. Attach the wire to the terminal block

securely so that its core cannot be seen, and no external force affects the connecting

section of the terminal block.

11) Firmly tighten the terminal screws. After tightening, verify that the wires are tightly fas-

tened.

12) Reinstall conduit plate.

13) Reinstall cable guide.

14) According to the piping direction, remove the shaded part of the left side of box (Fig.4)

or corner box (Fig. 5).

15) Reinstall VA clamp.

16) Reinstall electrical cover.

17) Reinstall panel assembly.

6/32-9/32 in.

(5-7 mm)

ø 3 in.

(75 mm)

Lead

wire

5/8 in.

(15 mm)

2-3/16 in.

(55 mm)

Less than 3/8 in.

(10 mm)

Conduit plate

Conduit pipe or

elbow joint

Lock nut

Elbow joint

(for right, left, or downward piping)

Less than 1-3/16 in.

(30 mm)

Fig. 1 Fig. 2

Fig. 3

Fig. 4

Corner box

Remove panel

for piping on right

side of unit

Remove panel for

piping on bottom

side of unit

Fig. 5

Box

Remove panel for piping

on bottom left side of unit

Remove panel

for piping on

left side of unit

4 in.

(100 mm)

Remark:

* A disconnect switch is required.

Check the local code.

**Use a ring tongue terminal in

order to connect a ground wire

to terminal.

Power supply

208/230 V AC,

1phase 2 wires,

60 Hz

INDOOR UNIT

Terminal block

208/230 V AC

1phase, 60 Hz

OUTDOOR UNIT

Terminal

block 1

Ground

Grounding terminal**

Grounding

terminal**

Disconnect

switch*

Pull tab to remove cable guide.

• Connect wires to the appropri-

ate terminals

• For future servicing, leave some

slack in the connecting wires.

Electrical cover

VA Clamp

Indoor

terminal

block

Electrical box

Cable guide

Grounding

terminal

Conduit pipe

Lock nut

Conduit plate

Elbow joint

Conduit plate

or