16

099565

psi

Pump

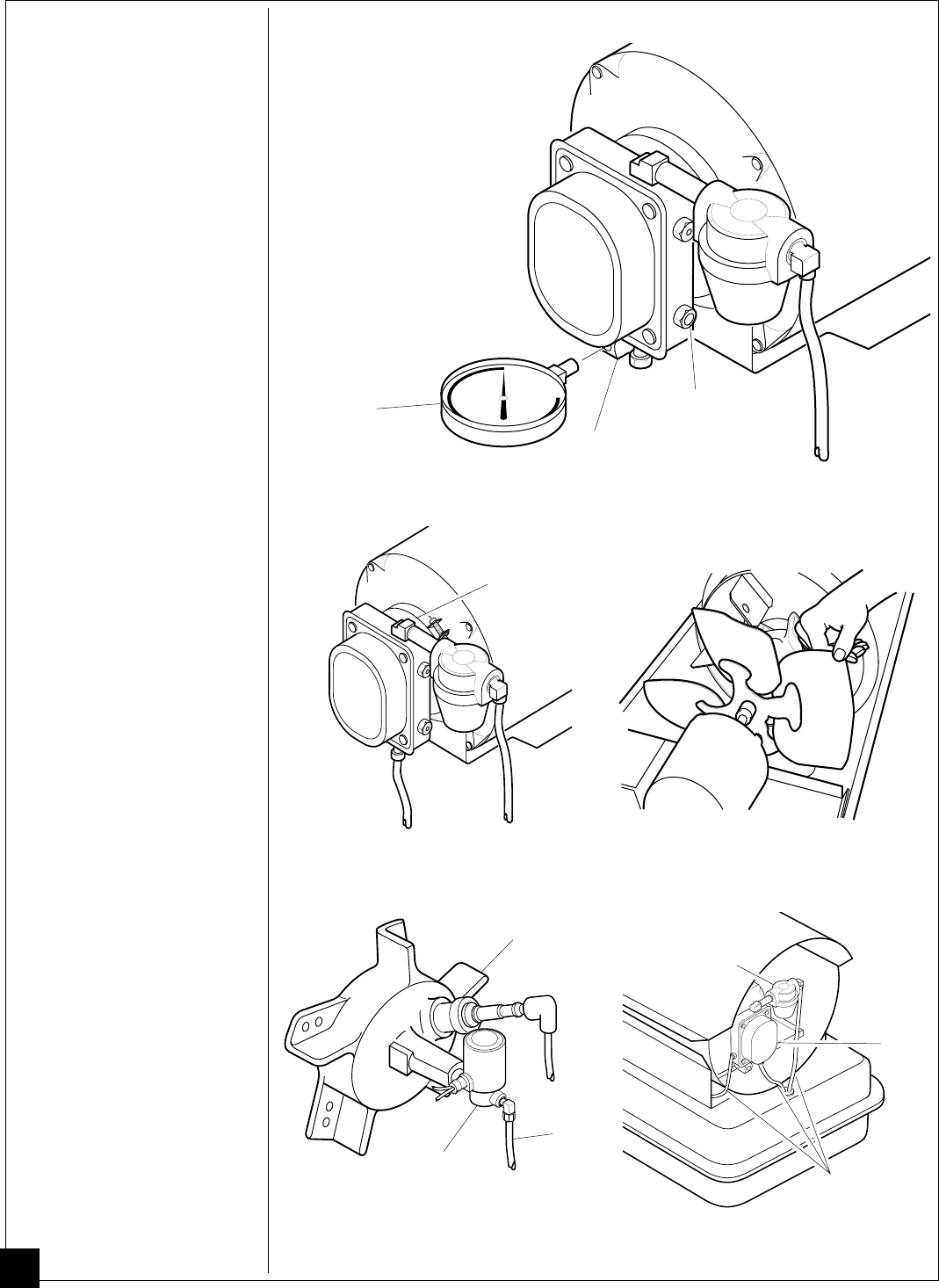

(Procedure if pump is binding)

1. Remove upper shell (see page

14).

2. Loosen hex screw on flange

clamp at rear of motor with

5/16" nut-driver (see Figure

11).

3. Turn fan with hand (see Figure

12).

4. If fan turns freely, tighten

screw on flange clamp.

5. If fan does not turn freely,

replace pump.

6. Replace upper shell.

Fuel Lines

(Procedure for tightening

fuel lines)

1. Remove upper shell (see page

14).

2. Use 7/16" wrench and tighten

fuel lines at solenoid valve (see

Figure 13), pump, and pump

fuel filter assembly (see Figure

14).

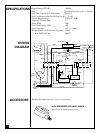

Pump Pressure

Adjustment

1. Remove pressure gage plug

from fuel pump port marked

“GAGE.”

2. Install accessory pressure

gage (part number M4574) to

fuel pump port marked

“GAGE” (see Figure 10).

3. Start heater (see Operation,

page 8). Allow motor to

reach full speed.

4. Adjust pressure to 100 psi.

Use small flat blade screw-

driver to turn slotted screw at

fuel pump port marked

“PRESS ADJ.” Turn screw

clockwise to increase

pressure. Turn screw

counterclockwise to decrease

pressure.

5. Remove pressure gage.

Replace pressure gage plug

in fuel pump port marked

“GAGE.”

Figure 10 - Adjusting Pump Pressure

Figure 11 - Location of Screw

on Flange Clamp

Hex Screw On

Flange Clamp

Figure 12 - Turning Fan with Hand

Fuel

Line

Solenoid

Valve

Burner Head

Pump

Pump

Fuel Filter

Assembly

Figure 13 - Fuel Line at

Solenoid Valve

Figure 14 - Fuel Lines at Pump and

Pump Fuel Filter Assembly

Fuel

Lines

Pressure

Gage

Fuel Pump Port

Marked “PRESS ADJ”

Fuel Pump Port

Marked “GAGE”