11

LDVR Series Direct Vent Gas Fireplace

10007317

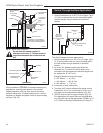

Outside Corner

Inside Corner

Termination Clearances

Termination clearances for buildings with combustible and noncombustible exteriors.

A =

Combustible

6"(152mm)

Noncombustible

2"(50mm)

B =

Combustible

6"(152mm)

Noncombustible

2"(50mm)

A

Balcony -

with no side wall

G =

Combustible &

Noncombustible

12"(305mm)

G

Balcony -

with perpendicular side wall

H = 24"(610mm)

J = 20"(508mm)

H

J

B

Recessed Location

C = Maximum depth of 48"

(1219mm) for recessed

location.

D = Minimum width for back wall

of a recessed location.

Combustible 38"(965mm)

Noncombustible 24"(610mm)

E = Clearance from corner in

recessed location.

Combustible 6"(152mm)

Noncombustible 2"(50mm)

C

D

C

E

V

V

Combustible &

Noncombustible

V

V

V

General Information Assembling Vent Pipes

Canadian Installations:

Venting system must be installed in accordance with the

current CSA-B149.1 installation code.

USA Installations:

The venting system must conform with local codes and/

or the current National Fuel Gas code ANSI Z223.1/

NFPA 54.

Only venting components manufactured by CFM Corpo

-

ration can be used in Direct Vent systems.

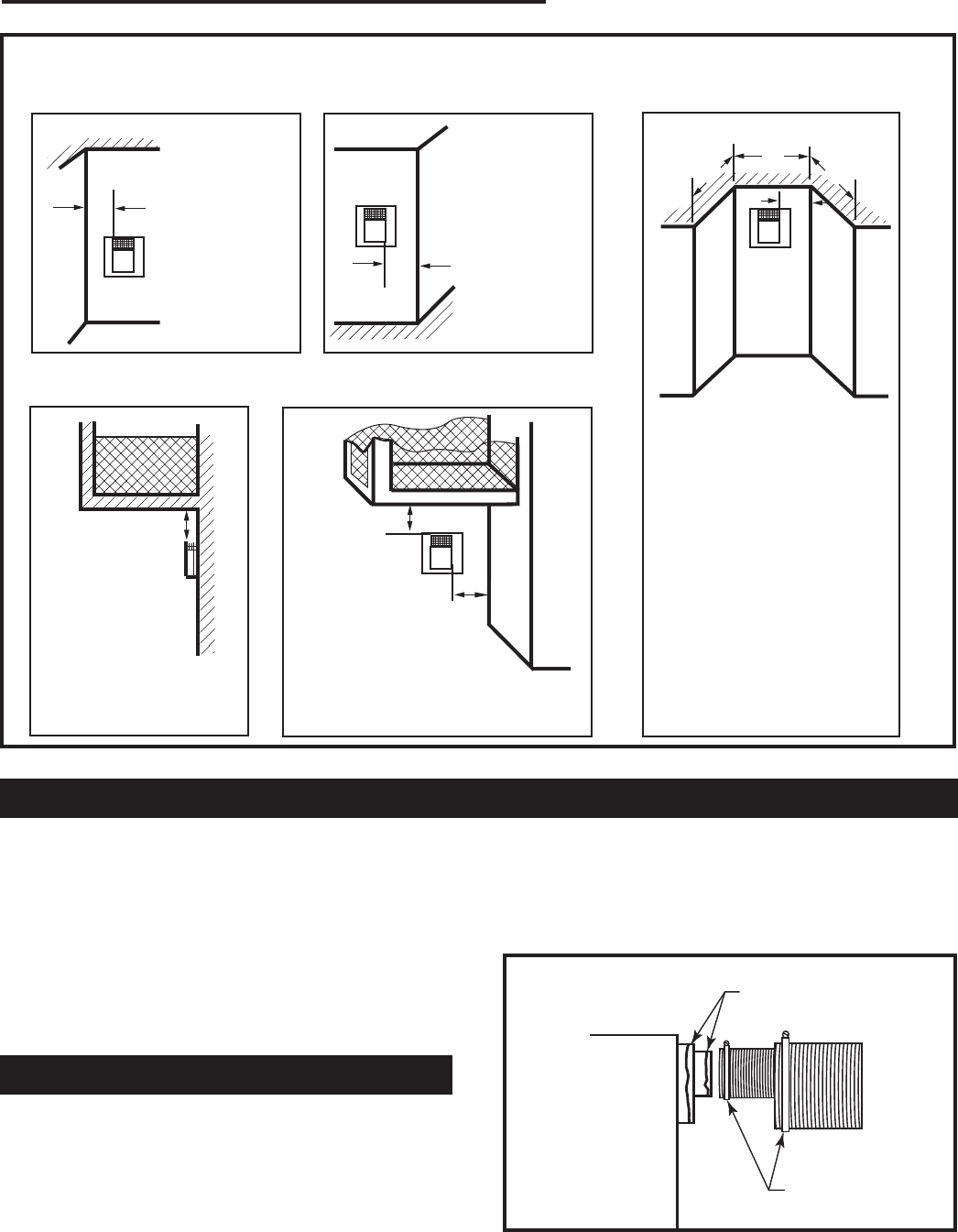

Flex Vent Pipes

Before joining the flex vent pipe to the unit, apply a

bead of high temperature sealant* (provided) to the 4”

pipe exiting the fireplace. Secure flex vent piep in place

with a hose clamp (provided).

*Be sure the flex pipe overlaps at least 1” (25mm) onto

the collars of the fireplace and termination. If the ter

-

mination has an internal bead, be sure to overlap and

secure 1” (25mm) past the bead.

584-15

Fig. 10 Termination clearances.

* Be sure the vent is actually crushed before proceed-

ing. Apply a tug to be sure the vent will not slip off the

collars.

Repeat process with 7” flex vent pipe. The same proce-

dure must be performed on the vent side.

FP1471

flex vent

Apply High Temperature

Sealant

Hose Clamp

FP1471

Fig. 11 Apply high temperature sealant to 4” and 7” pipes.