SPRINGS, PULLEYS, CABLES AND MOUNTING HARDWARE USED TO

BALANCE YOUR GARAGE DOOR ARE UNDER EXTREME TENSION AT ALL

TIMES AND CAN CAUSE SEVERE INJURY OR DEATH IF DISTURBED.

DO NOT ATTEMPT ADJUSTMENT.

Figure 6, page 8 illustrates several positions suitable for

mounting the operator; right hand or left hand, either wall mount

or ceiling mount.

CHAIN COUPLING MOUNTING

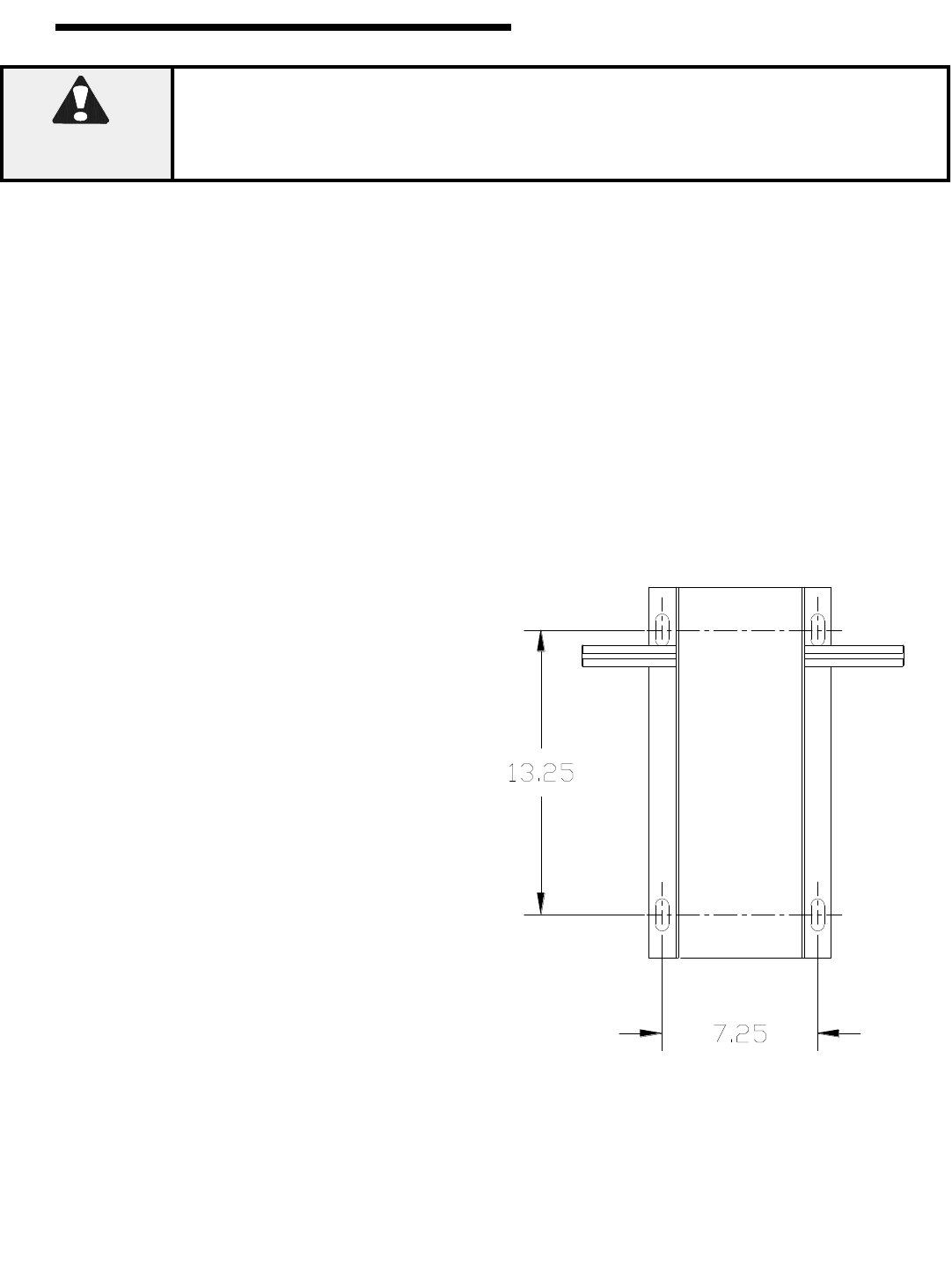

Refer to Figure 2 (at right), Figure 1, page 4 and Figure 7, page

9 for component identification and the operator mounting slot

locations. Place the sprockets [ 5 ] and [ 14 ] on the chosen side

of the torsion shaft of the door and on the corresponding end of

the output shaft of the operator, see Figure 3. The sprockets

should be kept as close as possible to the bearings. Fasten the

connecting link to each end of the door chain and loop the chain

over the sprocket [ 5 ] on the torsion shaft. Temporarily suspend

the operator in its mounting position using the chain over the

sprocket [ 14 ] at one end of the jackshaft and a rope or chain at

the mid point (to support the operator weight). With the chain

tight and straight and the jackshaft parallel with the torsion shaft,

trace the mounting slot on the mounting surface then lower the

operator to the floor.

IT IS ESSENTIAL THAT THE SURFACE

SUPPORTING THE OPERATOR BE RIGID

AND SECURE. FAILURE TO PROVIDE A FIRM

MOUNTING SURFACE WILL RESULT IN

DAMAGE TO THE DOOR TORSION SHAFT

AND THE PREMATURE FAILURE OF THE

OPERATOR.

If the construction permits, the operator should be mounted with

3/8 inch diameter bolts through the wall. If it is not feasible to go

through the wall, then use lag bolts to fasten the operator to the

mounting surface. Locate the four holes within the tracings of the

slots made in the previous step at the positions which will allow

for adjust-ment of the chain tension. After drilling the mounting

holes and instal-ling lag shields, if necessary, bolt the operator to

the mounting surface but do not completely tighten the bolts at

this time. Check the alignment of the sprockets, adjust their

positions on the shafts if necessary and tighten the set screws

securely on both sprockets. pulling downward on the operator to

remove slack from the chain, tighten the four mounting bolts.

Inspect the installation. There should be no slack in the chain but

neither should it be under severe tension which might shorten the

life of the bearings. If there is any flexibility in the system due

to construction of the surface supporting the operator or

noticeable deflection of the door shaft, it is advisable to install a

shaft support between the operator jackshaft and the door shaft

to prevent the loss of limit settings due to the possibility of the

chain jumping over the sprocket teeth. Shaft supports are

available from the factory.

If there isn‟t a keyway on the doorshaft, keep the sprockets

aligned and drill a 5/16” hole through the door drive sprockets

and door shaft. Insert roll pin, Item (2). See Figures 3 & 4.

BEFORE PROCEEDING WITH THE

OPERATOR INSTALLATION AND SETTINGS,

MAKE A FINAL CHECK FOR TIGHTNESS OF

ALL MOUNTING HARDWARE AND SET

SCREWS.

Proceed to “Chain Hoist and Floor Disconnect Installation”.

WARNING

107851

Figure 2

6

INSTALLATION INSTRUCTIONS