12

APPLICATION/INSTALLATION GUIDELINES

Location Guidelines

To ensure an adequate air supply,

locate drycoolers in a clean air

area, away from loose dirt and for-

eign matter that may clog the coil.

In addition, drycoolers must not

be placed near steam, hot air, or

fume exhausts. Also, drycoolers

should be no closer than 3 feet

from a wall, obstruction or adja-

cent unit with no obstructions over

the unit. Install drycoolers in a

level position to assure proper vent

and drain.

All drycooler legs have mounting

holes for securing the unit to steel

supports or concrete pads.

For roof installation, mount dry-

coolers on steel supports in accor-

dance with local codes. To

minimize sound and vibration

transmission, mount steel sup-

ports across load-bearing walls.

For ground installations, a con-

crete pad will support the load.

Drycooler Installation

The drycooler should be located

for maximum security and main-

tenance accessibility. Avoid

ground level sites with public

access or areas which contribute

to heavy snow or ice accumula-

tions. Utilize centrifugal fan dry-

coolers when placing a drycooler

in a building.

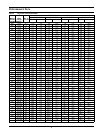

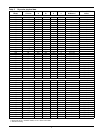

Electrical Requirements of

the Drycooler

Electrical service is required for

all drycoolers at the location of the

outdoor system. The power supply

does not necessarily have to be the

same voltage supply as required

by the indoor unit. This separate

power supply may be 208, 230,

460 or 575 volt, 60 Hz. For electri-

cal characteristics of the standard

voltage drycoolers, see Full Load

Amps (FLA) of the drycooler in

Tables 6 and 7 and FLA of the

pump, if used, in Table 8. Dual

element, time delay type fuses or

“HACR” circuit breakers at the

main power source. The only elec-

trical connection between the

indoor unit and the drycooler is a

two wire control interlock which is

field-connected when provided.

Glycol/Inhibitor Solution

The percentage of glycol to water

will be determined by the outdoor

ambient in which the system is

operating. Just as critical is the

inhibitor used with the glycol.

Commercial ethylene glycol

(Union Carbide Ucartherm, Dow

Chemical Dowtherm SR-1, and

Texaco E.G. Heat Transfer Fluid

100), when pure, is generally less

corrosive to the metals than water.

It will, however, assume the corro-

sivity of the water from which it is

prepared and may become increas-

ingly corrosive with use if not

properly inhibited. Proper inhibi-

tor maintenance must be per-

formed to prevent corrosion of the

glycol system. Consult glycol man-

ufacturer for testing and mainte-

nance of inhibitors.

Automotive antifreeze is unac-

ceptable and must not be used

in any glycol fluid system.

There are two basic concepts of

corrosion inhibition: They are clas-

sified as corrosion inhibitors or

environmental stabilizers. The cor-

rosion inhibitors function by form-

ing a surface barrier that protects

the metals. Environmental stabi-

lizers decrease corrosion by stabi-

lizing or favorably altering the

overall environment. An alkaline

buffer, such as borax, is a simple

example, since its prime purpose is

to maintain an alkaline condition

(ph above 7).

The quality of the water of dilu-

tion must be considered because

water may contain corrosive ele-

ments which reduce the effective-

ness of the inhibited formulation.

Surface waters that are classified

as soft and are low in chloride and

sulfate ion content (less than

100 ppm each) should be

employed.

Piping Considerations

CAUTION: When using water

under pressure to test the system

for leaks, immediately charge the

tested system with glycol. Com-

plete system drain-down cannot be

assured. Replacing broken, frozen

piping is a needless exercise. A

preferred test method utilizes com-

mon refrigerant gas pressurized

with nitrogen. A refrigerant type

leak detector will find even the

smallest leak when properly used.

Galvanized pipe or other com-

ponents should not be used

with an inhibited glycol system.

All fluid piping must comply

with local codes. Care in sizing

pipes will help reduce pumping

power and operating costs.

Manual shut-off valves and unions

should be installed at the supply

and return line of each major sys-

tem component. This permits rou-

tine service or emergency isolation

of the component.

Where connecting to a city water

supply, provide a disconnection

means. A city water source is desir-

able for initially charging the sys-

tem and as an emergency standby

cooling source.

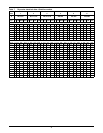

The minimum glycol temperature

to be supplied from the drycooler

determines whether the supply

and return lines should be insu-

lated to prevent condensation (see

Table 9).

Vents are required at system high

points to vent trapped air when

filling the system.

Since the system is not open to the

atmosphere, an expansion tank

must be provided for expansion

and contraction of the fluid with

temperature change. A relief

valve is also necessary.

A fill port is necessary for charg-

ing the system with glycol.

Depending on the complexity of the

system, various other devices may

be specified, such as pressure

gauges, valves, pumps and sensors.