11

COMPONENT ASSEMBLY/INSTALLATION

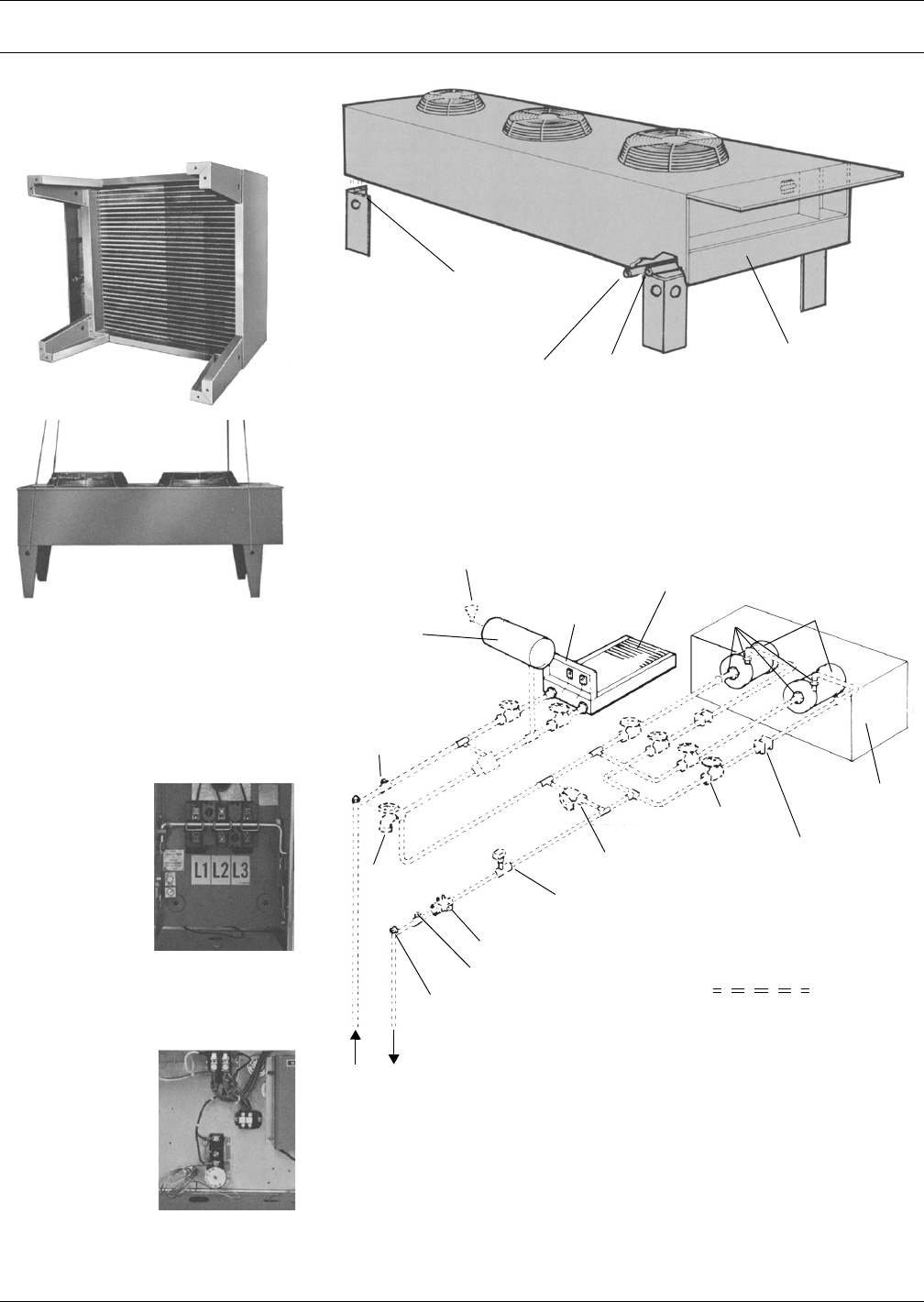

Leg Assembly

The legs are shipped loose and are

to be field mounted as shown with

the hardware provided.

Rigging

Holes in the drycooler legs permit

lifting the unit. Spreader bars are

required. Four, 6 and 8 fan models

have additional lifting eyes.

High Voltage Electrical

Connections

Line Voltage is

connected to the

terminal strip

or directly to

the factory sup-

plied locking

disconnect

(optional).

Check voltage

and compare to nameplate.

Low Voltage Electrical

Connections

A control inter-

lock between the

indoor and out-

door equipment

must be mini-

mum 16 ga. for

up to 75 ft. or not

to exceed 1 volt

drop in control

line.

Typical rigging

Figure 7 General arrangement diagram

Secure each leg to drycooler

frame at all four points shown

using hardware provided

Models 620 through 940 have 2 sets

of connections on end of unit

Electrical service

supply by others

Outlet

Inlet

Models 069-491

Pump

housing

Optional dual pump

system shown

Drycooler coil

Drycooler

electric box

Glycol

pumps

Fill*

Expansion

tank field

installed at

highest point

in system

Unions*

U

n

i

o

n

s

*

M

i

x

i

n

g

v

a

l

v

e

*

Hose

bib*

Pressure

port*

Air vents at top of risers*

Pressure port*

Flow regulating valve*

Flow switch supplied

with dual pump systems*

Check valves*

on dual pump

systems only

Gate or ball*

valve for

isolation (typ)

Gate or ball*

valve for bypass

Flow direction

* Components are not supplied by Liebert,

and all components shown may not be

necessary for system operation.

Field piping