Operation with Advanced Microprocessor with Graphics Control

22

3.7.2 Select Options

The following table is a list of options which should match the options installed with your unit and

should not need to change during normal operation.

3.7.3 Calibrate Sensors

The temperature and humidity sensors can be calibrated by selecting this menu item. “SENSOR”

shows the actual sensor reading or raw reading. “CALIBRATED” shows the sensor reading after the

calibration offset has been added. The temperature sensor can be calibrated ±5°F and the humidity

sensor can be calibrated ±10% RH. When calibrating the humidity sensor, the value shown will

always be % RH, even though absolute humidity control may be selected. If absolute humidity control

is selected, the Normal Status Display will display the adjusted reading and may not agree with the

relative humidity reading displayed while in calibration.

3.7.4 Calibrate Valve Actuator

For systems that use a valve actuator for chilled water or GLYCOOL cooling, the actuator timing may

be calibrated or adjusted. This is the time it takes for the valve to travel from full closed to full open.

It is programmable from 0 to 255 seconds. The factory default time is 165 seconds and should not be

changed unless the actual valve travel time is not correct. The full valve travel time is used by the

control to determine the appropriate valve position. For example, if the valve travel time is 165 sec-

onds and 50% cooling is being called for, the valve will open for 83 seconds to achieve 50% open. To

change the valve travel time, first enter the “CALIBRATE ACTUATOR” screen. The display will show

the present period used by the control for valve actuator full travel. Press ENTER and adjust the time

using the UP/DOWN arrows. When the correct time is displayed, press ENTER to store the new time

to memory.

3.7.5 Select Control Algorithm (Chilled Water and SCR Reheats only)

The type of system control method used by the microprocessor can be selected from the front panel.

The default setting is INTELLIGENT, which approximates the actions that a human operator would

take to maintain precise, stable control. The control logic uses Artificial Intelligence techniques

including “fuzzy logic” and “expert systems” methods to maintain precise, stable control and increase

reliability by reducing component cycles. PROPORTIONAL is a standard control method that uses

one gain factor (temperature sensitivity adjustment). TUNABLE PID (Proportional, Integral, and

Derivative) uses three gain factors selected by the operator. PID allows precision tuning, but requires

an experienced operator and seasonal adjustments. Note that if PID is selected, it is used for temper-

ature control while humidity will continue to use proportional control. For chilled water units with

the optional Variable Speed Drive, Intelligent is required for proper operation. Refer to 4.0 - System

Performance with Advanced Microprocessor Controls for more details on types of control.

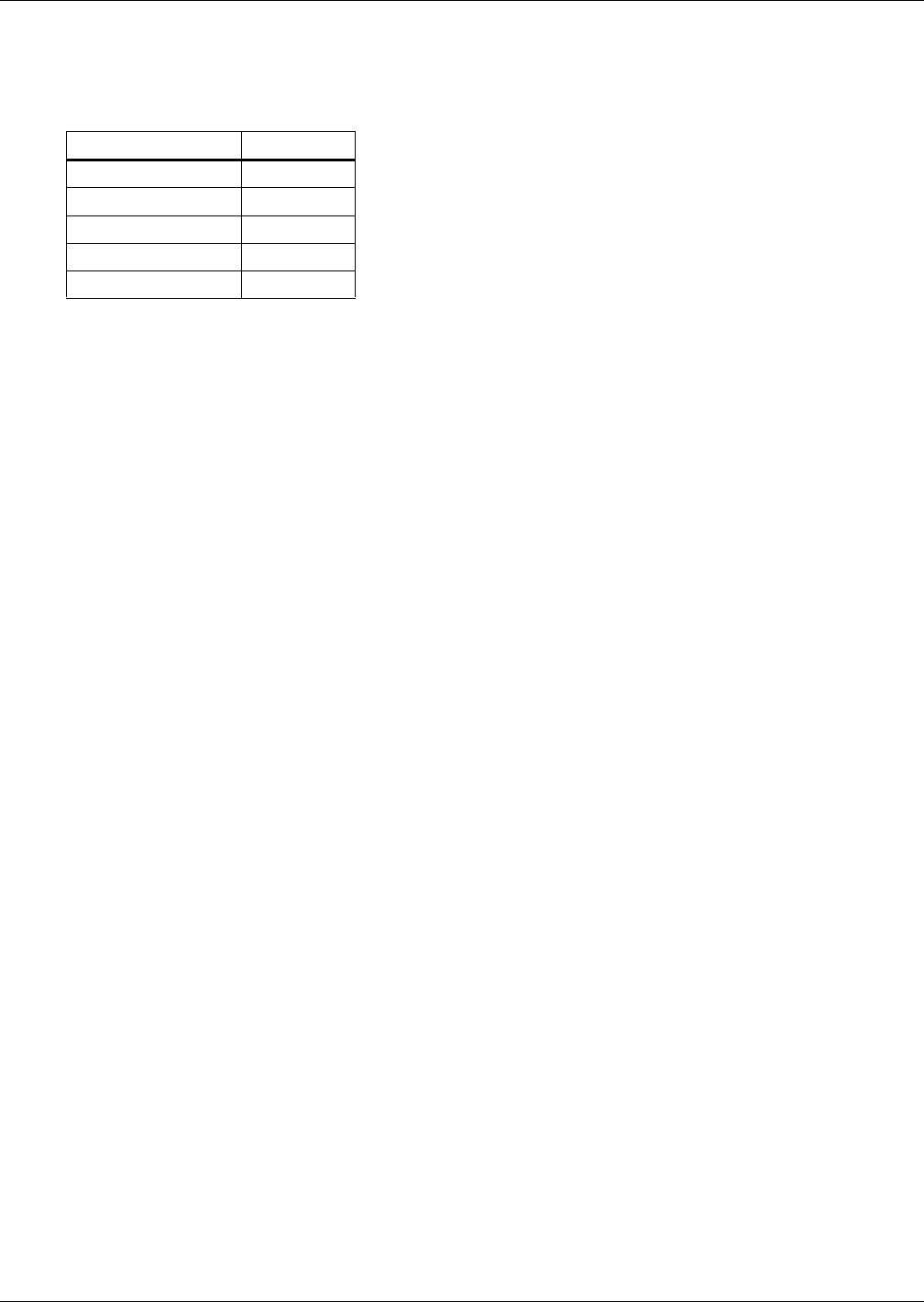

Table 10 Unit options

Option Selection

Reheat

1

YES or NO

Humidity YES or NO

Dehumidify YES or NO

Hot Gas Reheat

2

YES or NO

Stages of Reheat

3

2

1

Heating cannot be disabled on units with SCR reheats.

2

Hot gas reheat not available on units with SCR reheats.

3

Heat stages not selectable on units with SCR reheats.