PLANNING YOUR INSTALLATION – Model CI1000HT

PAGE 6

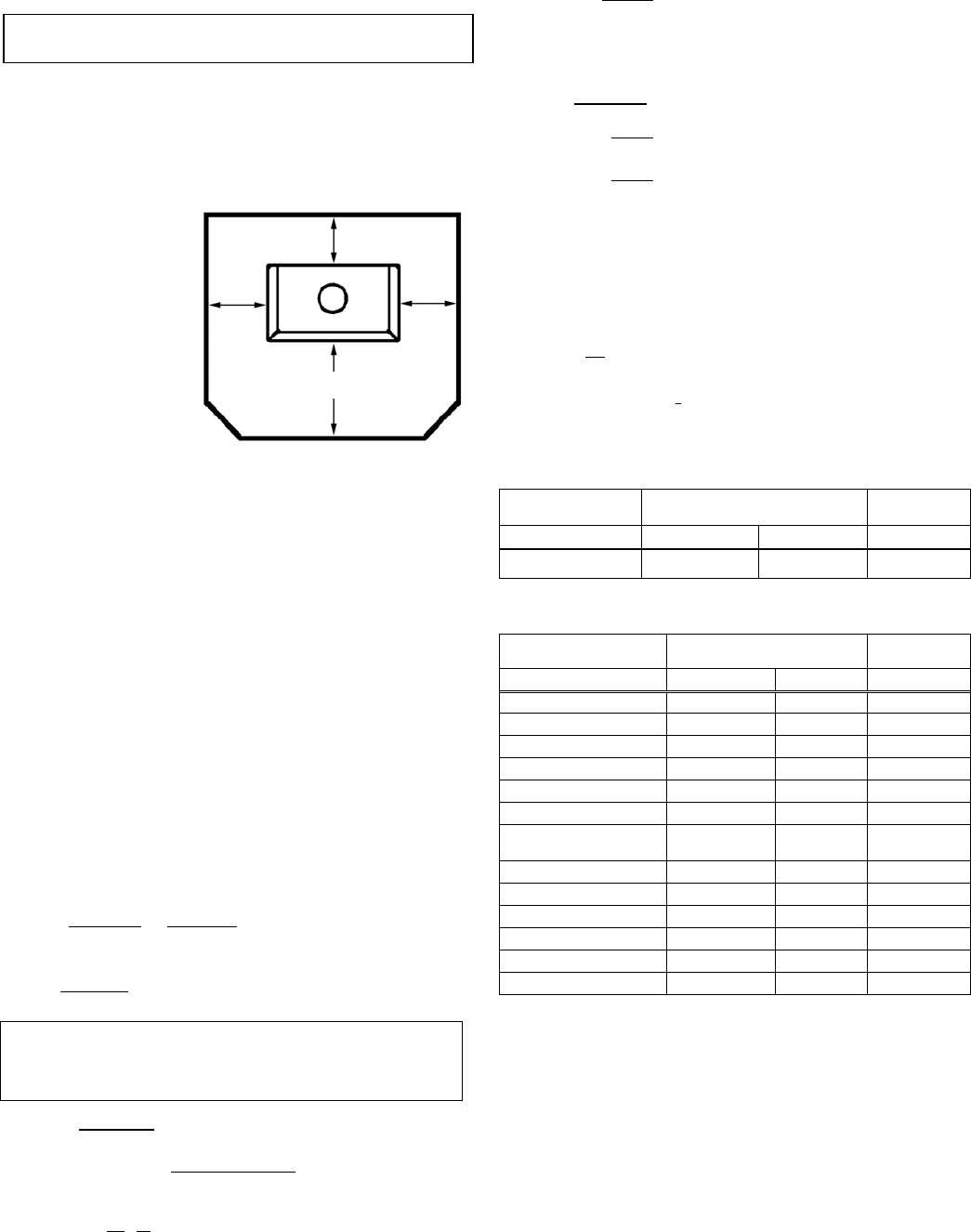

Top View

FOR INSTALLATIONS IN CANADA

MODEL CI1000H

T

FLOOR PROTECTION

The floor protector must meet or exceed the minimum ther-

mal requirements as defined on this page (see Floor Pro-

tection Using Alternate Material As Floor Protector). If the

floor protection is to be stone, tile, brick, etc., it must be

mortared or grouted to form a continuous noncombustible

surface. If a chimney connector extends horizontally over

the floor, protection

must also cover the

floor under connector

and at least 2" (51

mm) to either side.

The floor protector must

fully cover the area

beneath the appliance

and extend 18” to the

front, 8” to the sides,

and 8” from the back as

shown in the illustration

to the right.

FLOOR PROTECTION USING ALTERNATE MATERIAL

AS FLOOR PROTECTOR

The hearth pad or alternate material used as a floor pro-

tector must be constructed of a durable noncombustible

material having an equal or better thermal conductivity

value (lower k value) of k = .84 BTU / IN FT

2

HR °F or a

thermal resistance that equals or exceeds r = 1.19 HR °F

FT

2

IN/BTU with a minimum thickness of 1.45”. With these

values, determine the minimum thickness of the alternate

material required using the formula(s) and the table

shown here (see chart – Approved Alternative Materials

for Floor Protection).

Note: Any noncombustible material having a thickness of

1.45" (37 mm) whose k value is less than .84 or whose r

value is more than 1.19 is acceptable. If the alternate ma-

terial used has a higher k value or lower r value will re-

quire a greater thickness of the material used. In some

cases, if the k value is less or the r value higher, a thinner

material may be used.

Methods of determining floor protection equivalents:

To determine the thickness required for the alternate ma-

terial when either the k value or r value is known, use ei-

ther the k formula

or r formula:

Example: Durock Cement Board is to be used for the

floor protection. How thick must this material be? The fol-

lowing formulas

give the means of determining minimum

thickness required.

T

M

= minimum thickness required for alternate material

k

M

= k value per inch of alternate material

T

L

= minimum thickness of listed material

r

M

= r value per inch of alternate material

Using the k formula

:

Desired thickness k value of desire Minimum

of the alternate = material (per inch)

x thickness

material k value of listed of listed

material (per inch) material

T

M

(inches) = k

M

x T

L

.84

T

M

(inches) = 1.92 x .1.45”

.84

Answer using k: ~2.287 x ~1.45” = ~ 3.316” = ~ 3 5/16”

~ 3 5/16” thickness Durock Cement Board will be required.

Using the r formula:

T

M

(inches) = 1.19 x T

L

r

M

T

M

(inches) = 1.19 x .1.45”

.52

Answer using r: ~2.287 x 1.45” = ~3.316 =~ 3 5/16”

~ 3 5/16” thickness Durock Cement Board will be required.

At times it is important to know what combination of materials are

acceptable for use as floor protection. The “R values” are used to

determine acceptable combinations of materials because “R val-

ues” are additive where r and k values are not.

“R value” = 1

= r x thickness of material used

k

Example: “R value” = 1/k = r x thickness of material used. Given that

the required “R value” for a suitable floor protector used must be equal to

or greater than:“R” = r x T

L

= 1.19 x 1.45” = ~ 1.73.

Listed Material

Listed Material Thermal Values Listed Min.

Thickness

k (per inch) r (per inch) T

L

Listed Material → .84 1.19 1.45”

Approved Alternate Materials for

Floor/Hearth Protection (**)

Alternative

M

ate

ri

a

l

s

↓

Thermal Values * Minimum

Thickness

k (per inch) r (per inch) T

M

Kaowool M Board .47 2.13 * 1.45”

Micore 160 .35 2.86 * 1.45”

Micore 300 .46 2.18 * 1.45”

Durock Cement Board 1.92 .52 3.5/16”

Hardibacker 1.95 .51 3 3/8”

Hardibacker 500 2.30 .44 4”

Cultered Stone

Hearthstone

2.82 .35 4 7/8”

Wonderboard 3.23 0.31 5 9/16”

Face brick 9.00 0.11 15 9/16”

Common brick 5.00 0.20 8 5/8”

Cement mortar 5.00 0.20 8 5/8”

Ceramic tile 12.5 .08 21 9/16”

Marble ~20.0 ~.05 34 9/16”

Note: To convert inches to millimeters divide by .03937.

(*) After minimum thickness is calculated, the thickness can be

no less than 1.45” (36.8mm).

(**) If the floor protector to be used is a noncombustible mate-

rial and is NOT listed on this chart on this chart, the manufac-

turer of the material must provide either the listed k-value per

inch or r-value per inch and the minimum thickness will need to

be calculated per instructions on this page.

8" (203 mm)

8"

(203 mm)

18" (457 mm)

8"

(203 mm)