Thisunitisnotequippedwithafilteror rack.A field-pro-

videdhigh-velocityfilterisrequiredfortheunittooperate

properly.Table1listsrecommendedfiltersizes.

Afiltermustbeinplaceanytimetheunitisoperating.

Furnace

Cabinet Size

14-1/2"

17-112"

21"

24-1/2"

TABLE 1

Filter Size

Side Return

16X25X 1 (1)

16X25X 1 (1)

16X25X 1 (1)

16 X 25 X 1 (2)

Bottom Return

14X25X1 (1)

16X25X1 (1)

20X25X 1 (1)

24X25X 1 (1)

Use industry-approved standards to size and install the

supply and return air duct system. This will result in a quiet

and low-static system that has uniform air distribution.

NOTE - Do not operate the furnace with an external static

pressure that exceeds 0,5 inches w,c, Higher external stat-

ic pressures may cause erratic limit operation,

Supply Air Plenum

If the furnace is installed without a cooling coil, a removable

access panel must be installed in the supply air duct, The

access panel should be large enough to permit inspection

(either by smoke or reflected light) of the heat exchanger

for leaks after the furnace is installed, The furnace access

panel must always be in place when the furnace is operat-

ing and it must not allow leaks into the supply air duct sys-

tem,

Return Air Plenum

Return air must not be drawn from a room where this

furnace, or any other gas appliance (ie., a water heat-

er), is installed. When return air is drawn from a room, a

negative pressure is created in the room, If a gas ap-

pliance is operating in a room with negative pressure, the

flue products can be pulled back down the vent pipe and

into the room, This reverse flow of the flue gas may result

in incomplete combustion and the formation of carbon

monoxide gas. This toxic gas might then be distributed

throughout the house by the furnace duct system,

In upflow applications, the return air can be brought in

through the bottom or either side of the furnace. If a fur-

nace with bottom return air is installed on a platform, make

an airtight seal between the bottom of the furnace and the

platform to ensure that the unit operates properly and

safely, Use fiberglass sealing strips, caulking, or equiva-

lent sealing method between the plenum and the furnace

cabinet to ensure a tight seal, Ifa filter is installed, size the

return air duct to fit the filter frame.

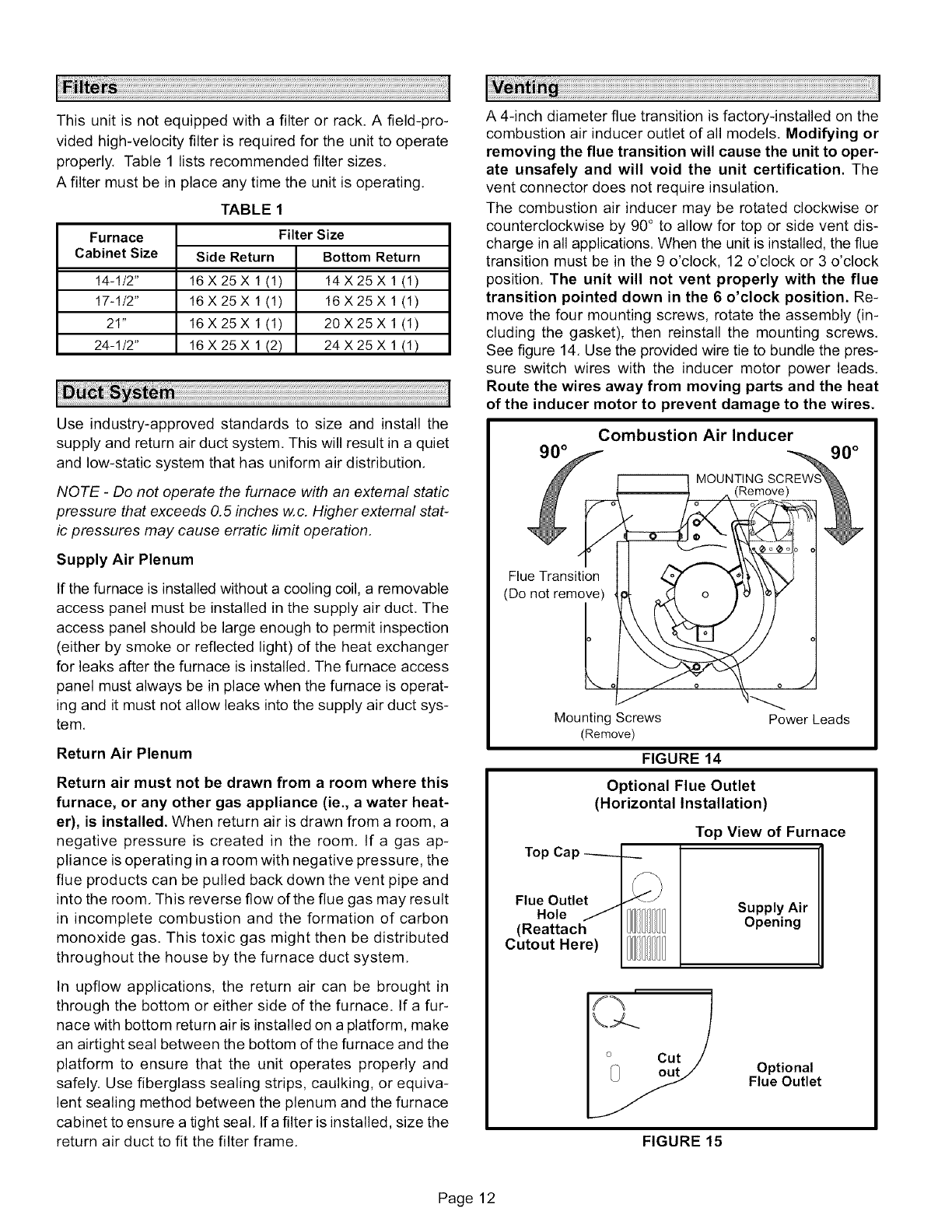

A 4-inch diameter flue transition is factory-installed on the

combustion air inducer outlet of all models. Modifying or

removing the flue transition will cause the unit to oper-

ate unsafely and will void the unit certification. The

vent connector does not require insulation.

The combustion air inducer may be rotated clockwise or

counterclockwise by 90° to allow for top or side vent dis-

charge in all applications. When the unit is installed, the flue

transition must be in the 9 o'clock, 12 o'clock or 3 o'clock

position. The unit will not vent properly with the flue

transition pointed down in the 6 o'clock position. Re-

move the four mounting screws, rotate the assembly (in-

cluding the gasket), then reinstall the mounting screws.

See figure 14. Use the provided wire tie to bundle the pres-

sure switch wires with the inducer motor power leads.

Route the wires away from moving parts and the heat

of the inducer motor to prevent damage to the wires.

Combustion Air Inducer

Flue Transition

(Do not remove)

Mounting Screws

(Remove)

FIGURE 14

Power Leads

Optional Flue Outlet

(Horizontal Installation)

Top View of Furnace

Top Cap ----__ _

Flue Outlet _<_J

Hole /

(Reattach II 111

Cutout Here)

Supply Air

Opening

Optional

Flue Outlet

FIGURE 15

Page 12