Note - It is recommended that rack be converted

to 20 inch filter size if filter is installed elsewhere

in return air duct.

3-In applications where rack uses a 16 inch

(50.8cm) filter, remove filler piece before cutting

rack opening. See figure 4.

4 - Cut four strips from rollofadhesive-backedfoam

tape (provided) to fit filter rack flanges, Apply to

flanges.

5 - Secure filter rack to cabinet as shown in figure 4.

6 - Cut opening in filter rack as shown in figure 4,

7 - In applications where rack uses a 16 inch (50,8cm)

filter, remove rack from cabinet, re-install filler

piece, then re-install rack to cabinet.

8-Install existing filter, unless filter is located

elsewhere in the return air duct,

9- Attach door to filter rack with thumb screws

provided.

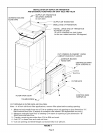

II - Internal Filter Rack

(Used with kit CAT#16L25)

Note - If filter is not to be located inside of unit,

installation of this filter kit is not required.

1 - Lay G26 unit on its side and cut out return air

opening in cabinet at knockout guides, See G26

installation instructions.

2 - Install filter rack top and bottom inside unit as

shown in figure 5, tn right side installations

wiring must be carefully worked around.

3 - Install existing filter,

4 - Slide door into filter rack bottom seam and align

with filter rack top securing hole. Attach with

thumb screws provided.

5- Securewiring awayfrom filter access areawith two

provided wire ties. Use existing screws in existing

screw locations to prevent accidental damage to

control board(s)/wiring by drilling of new holes.

B - Supply Air Transition Installation

1 - Cut four strips from roll ofadhesive-backedfoam

tape (provided) to fit supply air transition flanges

at G26 unit connection. Apply to flanges. See

figure 4 or 5,

2- Position supply air transition on unit top as

shown in figure 4 or 5.

3- If required, internally insulate transition with

foil-faced insulation (field provided) and fasten

with kit provided insulation pins and washers,

4- Use four screws and/or bend cabinet flanges

over transition tips to secure transition.

C - Unit Installation

1 - Align unit with existing supply air plenum (coil

cabinet in air conditioning applications) and

return air plenum.

Note - If required, use existing G14 isomode pads

to achieve this alignment.

2 - Make connections to unit, In bottom return air

applications, follow the instructions provided

with the G26 unit, note especiallythe warnings in

the "Return Air Opening Guidelines" section.

3 - ff air conditioning coil was removed, re-install

coil, reconnect line set and coil drain. See

condensing unit installation instructions for

re-processing of refrigerant system.

Note - Coil drain line must not be connected to

heat exchanger condensate drain line. If lines

were connected, debris from evaporator could

affect heat exchanger operation.

4- Make tow voltage wiring entrance to unit on

opposite side from return air connection to

prevent blocking filter access. Connect as

illustrated in G26 installation instructions.

5 - Connect high voltage wiring as outlined in G26

installation instructions,

6- Connect gas piping as outlined in G26

installation instructions.

Consult local codes for flexible connector

installation restrictions on G26 furnace.

7 - Connect venting as outlined in G26 installation

instructions.

Note - Mufflers can not be used in G26

installation. Check existing venting for size

(diameter and length). It should meet the

specifications as outlined in G26 installation

instructions.

8 - Connect heat exchanger condensate drain line as

shown in figure 6 and as outlined in G26 unit

installation instructions, (A 1/2" PVCto 1/2" CPVC

bushing is provided for connecting PVC to

existing CPVC condensate line,)

9 - Continue with Unit Start-up Section as outlined

in G26 installation instructions.

Note - See G26 installation instructions for heat

anticipation settings.

Page 4