18

Gas Line Installation

This stove must be connected to the gas line in accordance with local

codes and/or the National Fuel Gas Code, ANSI Z223.1 (In Canada, the

current CAN/CSA B149.1 installation code). The gas line screws into the

gas valve at the back of the stove 2-1/2” in from the left side of the stove

and 8-1/2” up from the base of the unit. After connecting the gas line, all

joints in the line and connections at the valve should be checked for leaks.

After connecting the gas line, all joints in the line and connections at the

valve should be checked for leaks before final positioning of the unit.

Conduct a gas leakage test of the appliance piping and control system

downstream of the shutoff valve in the supply line to the appliance.

Gas Pressure Requirements

A MAJOR CAUSE OF OPERATING PROBLEMS WITH GAS

APPLIANCES IS IMPROPER GAS PRESSURE!

The most important item to check during the initial installation

and the first thing to check when operating problems occur is

gas pressure! This appliance will not function properly unless

the required gas pressure is supplied. See the table on this

page for gas pressure requirements.

Two pressure taps are provided on the appliance’s valve to check gas

pressures. To access the taps, remove the two socket head screws from

the valve control panel. The taps are located below the on/off/pilot knob.

The left tap is the inlet (supply) pressure side. To check inlet pressure

(with the appliance burning) insert a small flat-bladed screwdriver into

the tap and turn a half-turn counterclockwise. Cover the tap with the

line from the manometer and check the pressure. Close the tap gently

but securely after completing the check. The manifold (outlet) tap is to

the right of the inlet tap. To check manifold pressure (with the appliance

burning at the high burn setting) insert a small flat-bladed screwdriver

into the tap and turn a half-turn counterclockwise. Cover the tap with the

line from the manometer and check the pressure. Again, close the tap

gently but securely after completing the check. Check the taps for gas

leaks with a gas leak test solution (retighten if necessary).

If the pressure is not sufficient, make sure the gas supply line is large

enough, the supply regulator improperly adjusted and the total gas load

for the residence does not exceed the amount supplied.

LP and Natural Gas Supplies

This appliance is equipped from the factory for use with natural gas only

as specified on the Safety / Listing label attached to the appliance. This

appliance can only be operated using propane gas (LP) if a certified fuel

conversion kit provided by Lennox Hearth Products is installed by a

qualified service technician.

Also check the orifice size on the label on the igniter bracket. It must be

the correct size for the fuel and altitude.

Do not run propane tank dry. Running the tank dry may cause

a hazardous condition due to pressure drop in empty tank.

Solid fuel is NOT to be used with this unit.

Fuel

Type

Inlet Pressure Manifold Pressure

Desired Minimum Maximum On Hi

Fire

On Lo

Fire

Natural

Gas

7" WC 5" WC 10.5" WC 3.5" WC 1.8" WC

LP Gas 11" WC 11" WC 13" WC 10" WC 6.0” WC

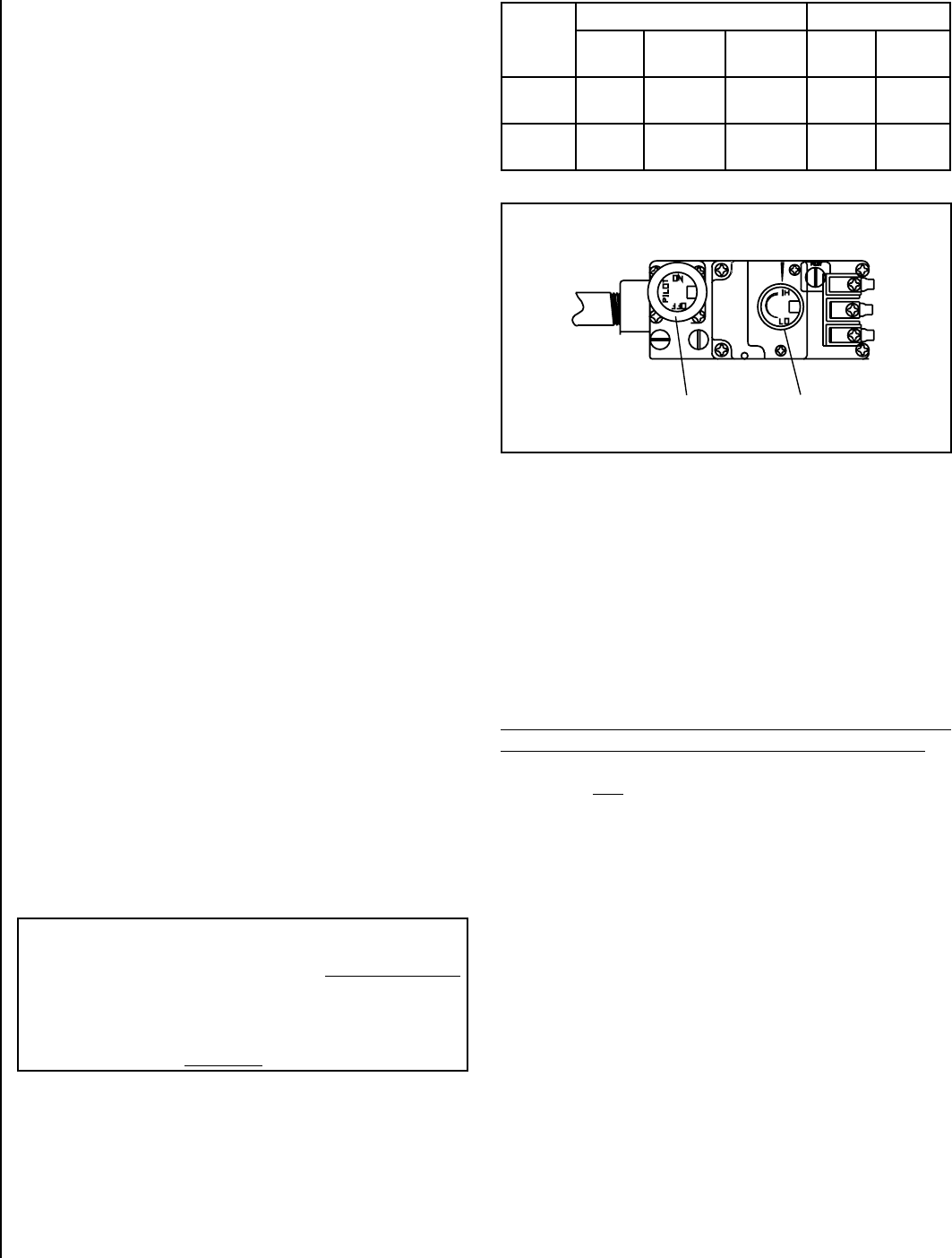

SIT Millivolt Gas Valve

Gas Control Knob

(Pilot / On / Off)

Flame Height Control

Knob (HI/LO)

The appliance must be isolated from the gas supply piping system

by closing its equipment shutoff valve during any pressure testing of

the gas supply piping system at test pressures equal to or less than

1/2 psig (3.5 kPa).

The appliance and its appliance main gas valve must be disconnected

from the gas supply piping system during any pressure testing of that

system at test pressures in excess of 1/2 psig (3.5 kPa).