23

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

LENNOXHEARTHPRODUCTS•MERIT

®

SERIESDIRECT-VENTCONTEMPORARYDESIGNGASFIREPLACES•MODELMLDVTCD-35•INSTALLATIONINSTRUCTIONS

D. Install Firestop / Spacers at ceilings and walls

- When Secure Flex penetrates a wall or ceiling,

a firestop / spacer is required: use the SF4.5 VF

firestop / spacer for ceilings and the SF4.5 HF

firestop / spacer for walls. See the appropriate

sections and Figures shown throughout the vent-

ing section for their installation requirements.

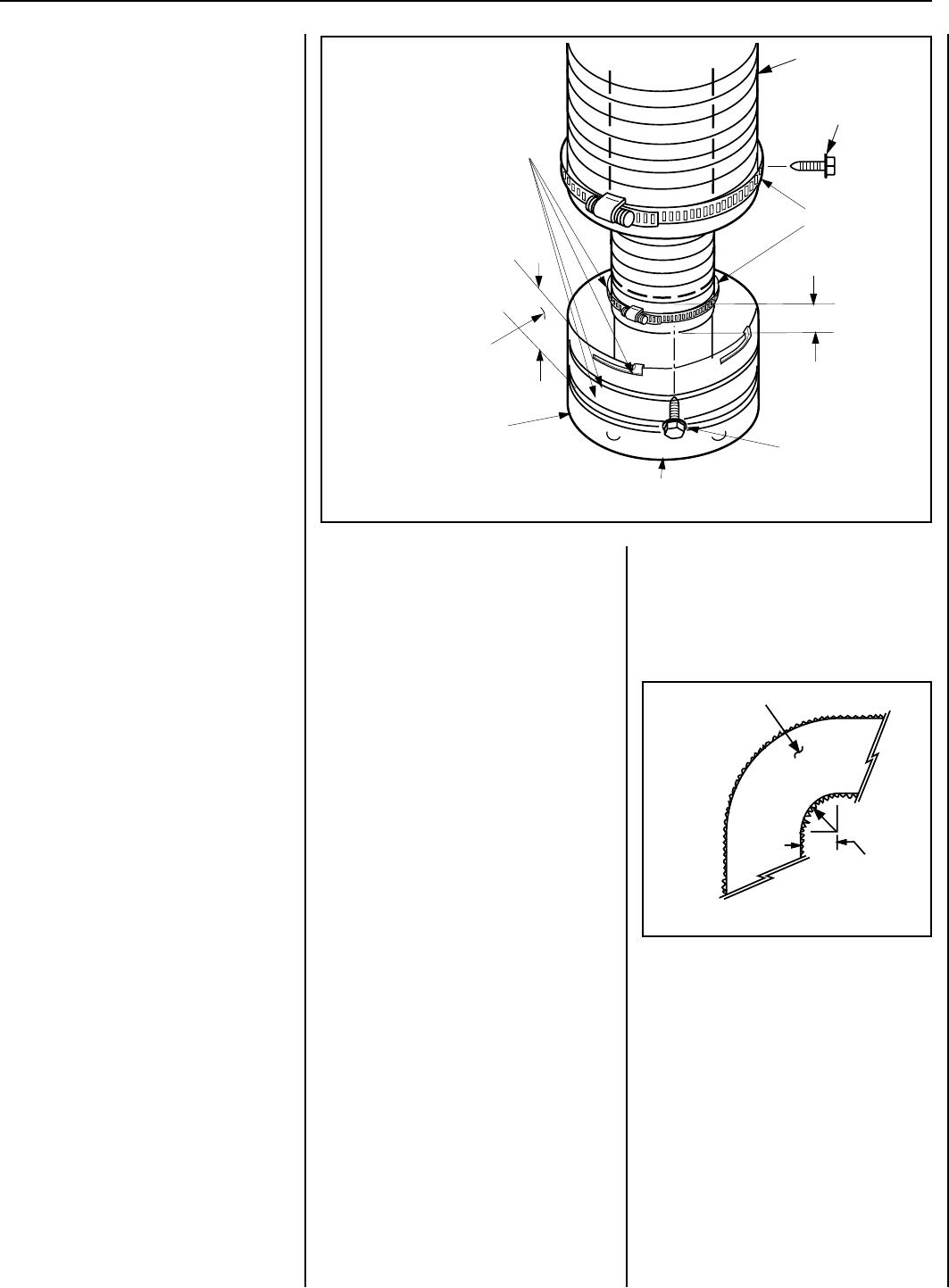

APPLY ONLY MIL-PAC BLACK

HIGH TEMPERATURE SEALANT

(Cat. No. 10K81) to the outside

surface of both collars of the

adapter (be especially careful to

fill the grooves of the outer collar

to be covered by the flexible pipe)

and slide flexible pipe over inner

and outer adapter collars.

1 3/4 inch (44 mm) Flexible

Pipe and Adapter Outer Collar

Overlap

Adapter (SV4.5RF)

Attach adaptor to appliance

Collar, or secure vent sections

Flex Vent

Gear Clamps

Securing Screw

- 3 places, 120° apart

(equally spaced) just

below gear clamp

1 3/4 in. (44 mm) Flexible

Pipe and Adapter Inner Collar

Overlap

VERTICAL OR HORIZONTAL VENTING USING

KITS AND COMPONENTS

Secure Flex™ venting kits and components

may be used in any venting application in place

of rigid Secure Vent™ (SV4.5) direct-vent

components. All restrictions, clearances and

allowances that pertain to the rigid piping apply

totheexibleventing.Secure Flex kits may

not be modified; also, under no circumstances

may separate sections of flex pipe be joined

together.

Using adapter (SV4.5RF), Secure Flex kits

may be added to the end of a vent run made

up of rigid Secure Vent (SV4.5) vent sections

provided that doing so does not violate any of

the venting length, height, routing, horizontal

to vertical ratio requirements or clearance

considerations detailed in this manual.

Secure Flex kits come with an adapter that

can be fitted to the inclined channel end of

the last Secure Vent (SV4.5) vent section in a

rigid system in the exact same fashion as any

other Secure Vent section. Align the dimpled

end of the adapter over the previously installed

section or appliance collar, adjusting the radial

alignment until the four locking dimples of the

adapter are aligned with the inlets of the four

incline channels of the last vent section or collar.

Push on the adapter until it fully engages, then

twist the adapter clockwise running the dimples

down and along the incline channels until they

seat at the end of the channels.

Attach the flexible vent to the adapter as fol-

lows (see also Figure 33):

A. Install the Inner Flex Pipe -

1. Install the small gear clamp loosely around

theinnerexibleventpipe,pushitbackout

of the way.

2. Apply a bead of Mill-Pac Black (700° F) high

temperature sealant - Catalog No. 10K81

to the inner adapter collar, approximately

1/2 inch from the end.

3.Pullandextendtheinnerexibleventpipe.

4.Slidetheinnerexpipeovertheadaptercol-

lar.Ensuretheexibleventpipecompletely

engages the adapter collar to a distance of 1

3/4 inches from the end, and that it is free

from damage or tears.

5. Slide the gear clamp down and tighten it

fullytosecuretheexibleventtotheadapter

inner collar approximately 3/4 inch from the

endoftheex.

6. Install three screws, 120 degrees apart,

throughtheexibleventpipeandintothe

adapter collar just below the gear clamp to

provide additional security to the connec-

tion.

B. Install the Outer Flex Pipe -

1. Install the large gear clamp loosely around

theouterexibleventpipe,pushitbackout

of the way.

2. Apply a bead of Mill-Pac Black (700° F, high

temperature sealant - Catalog No. 10K81)

to the outer adapter collar; to the grooves

of the collar which extend approximately 1

inchfromtheendandtotheatsurface,

approximately 1-3/8 inches from the end.

3.Pullandextendouterexibleventpipe.

4.Slidetheouterexpipeovertheadaptercol-

lar.Ensuretheexibleventpipecompletely

engages the adapter collar to a distance of

1-3/8 inches from the end, and that it is free

from damage or tears.

5. Slide the gear clamp down and tighten it

fullytosecuretheexibleventtotheadapter

outer collar approximately 3/4 inch from the

endoftheex.

6. Install three screws, 120 degrees apart,

throughtheexibleventpipeandintothe

adapter collar just below the gear clamp to

provide additional security to the connec-

tion.

C. Route Flex Vent -

Ensurethattheexventisproperlyroutedto

provide the required clearance. Do not allow the

exibleventtobendinaradiustighterthan5"

(127 mm). Refer to Figure 34. Space out the

internalexventspacersevenly-approximately

every 6 inches - and avoid kinking of inner pipe.

Supporthorizontalsectionsofexwithmetal

straps at 2 foot (0.61 m) intervals.

E. Attach Flex Vent to Termination -

Secure Flex components can be purchased

separately and attached to bulk lengths of Se-

cure Flexexibletubingcuttosizeatthejob

site.SecuretheexibleventtotheSecure Flex

terminations in the same manner (see Figure

33) as it was attached to the adapter.

Note: Secure Flex vent must be attached to Se-

cure Flex terminations only. DO NOT substitute

Secure Vent terminations or the Secure Vent

adapter for Secure Flex components. The col-

lars of Secure Flex terminations and adapters

have a different diameter than that used with

the Secure Vent pipe. Additionally, Secure Flex

components have an extended length center

tube for use in attaching the flexible vent.

Figure 33

Flexible Vent

Section

5” (127 mm)

Radius

Minimum

Figure 34

NOTE: Outer pipe is pulled away to

show the detail of the inner pipe.

Securing Screw - 3 places,

equally spaced, just below

gear clamp.