7

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

LENNOX MERIT

®

SERIES B-VENT GAS FIREPLACES • 42" LMBV MODELS • INSTALLATION INSTRUCTIONS

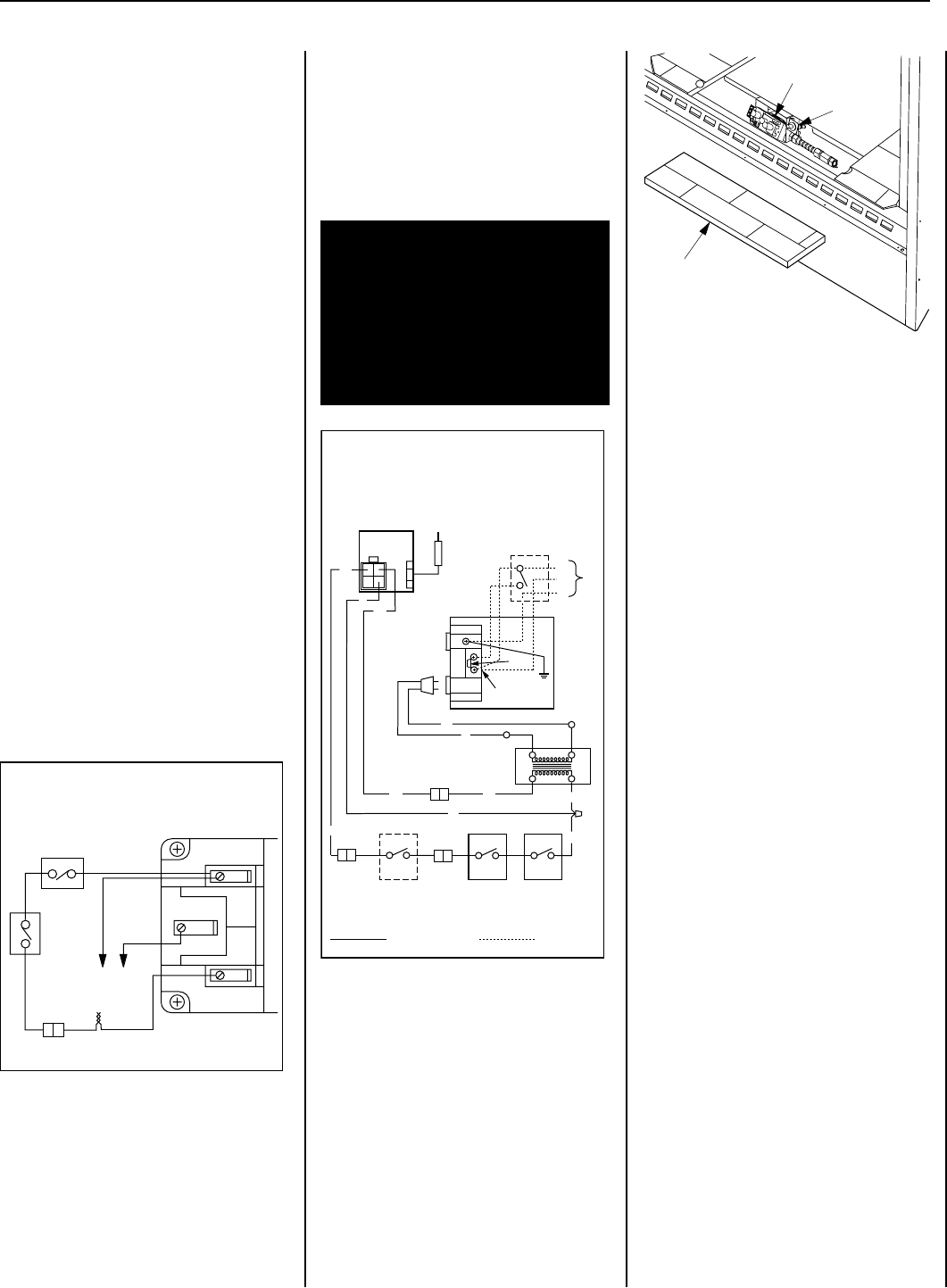

Figure 11

Step 5. Field Wiring – Refer to Section A for

millivolt appliances and Section B for electronic

appliances.

A. Millivolt Wiring – The gas valve has been set

in place and has been pre-wired at the factory. No

additional wiring is required unless the optional

wall switch or optional remote control kit is to

be installed. Locate the optional wall switch or

optional remote control in the desired location

and connect the millivolt wire (see Figure 11 ).

CAUTION: DO NOT CONNECT THE WALL

SWITCH TO A 120V POWER SUPPLY.

Note: Optional wall switch not supplied. If the

optional wall switch is not installed, the ends of

the 15' coiled wire must be connected with a wire

nut (not supplied) for the appliance to operate.

Figure 12

Step 6. Connecting Gas Line – Make gas line

connections. All codes require a shut-off valve

mounted in the supply line. Figure 15 illustrates

two methods for connecting the gas supply. The

ex-line method is acceptable in the U.S., how-

ever, Canadian requirements vary depending on

locality. Installation must be in compliance with

local codes. The gas control valve is located in

the lower control compartment. To access the

valve remove the refractory access panel and

set aside (Figure 13 ).

B. Electronic Wiring – The electronic appliance

must be connected to the main power supply.

To install:

1. Route a 3-wire 120V 60Hz power supply to

the appliance junction box and ground. (See

Figures 12 and 14 ).

IMPORTANT: Ground lead must be connected

to the green screw located on the outlet box.

See Figure 12 . Failure to do so will result in a

potential safety hazard. The appliance must

be electrically grounded in accordance with

local codes or, in the absence of local codes,

the National Electrical Code, ANSI/NFPA

70-(latest edition). (In Canada, the current

CSA C22-1 Canadian Electrical Code.)

The millivolt control valve has a 3/8"

(10 mm) NPT thread inlet port. The electronic

control valve has a 1/2" (13 mm) NPT thread

inlet port and is tted with a 1/2" x 3/8" (13

mm x 10 mm) NPT fitting. Both the millivolt

and electronic models are tted with a 3" (76

mm) long nipple, 3/8" NPT. Plan the connec-

tions accordingly.

Secure all joints tightly using appropriate

tools and sealing compounds (ensure propane

resistant compounds are used in propane

applications).

Turn on gas supply and test for gas leaks, us-

ing a gas leak test solution (also referred to as

bubble leak solution).

Note: Using a soapy water solution (50% dish

soap, 50% water) is an effective leak test solu-

tion but it is not recommended, because the

soap residue that is left on the pipes/fittings

can result in corrosion over time. Never use

an open ame to check for leaks.

A. Light the appliance (refer to the lighting

instructions label in the control compartment

or in the Care and Operation Instructions).

B. Brush all joints and connections with the gas

leak test solution to check for leaks. If bubbles

are formed, or gas odor is detected, turn the

gas control knob to the “OFF” position. Either

tighten or refasten the leaking connection and

retest as described above.

C. When the gas lines are tested and leak free,

be sure to rinse off the leak testing solution.

D. When the gas lines are tested and leak free,

observe the individual tongues of ame on

the burner. Make sure all ports are open and

producing ame evenly across the burner. If

any ports are blocked, or partially blocked,

clean out the ports.

Figure 13

Refractory

Access Panel

SIT Valve Shown

Gas Controls

on Valve

Piezo

Ignitor

2. Locate and install a low voltage (24V) wall

switch (not supplied) in the desired location.

Connect the low voltage wire to this switch

(see Figure 12 ).

3. After wiring is complete, replace the appliance

junction box cover and secure with the hex head

screws previously removed.

Maximum overall height of the vent system and

appliance should not exceed 40 feet (12.19 m).

Install the B-vent system in accordance with

the vent manufacturer's instructions.

CAUTION: THIS APPLIANCE CANNOT BE

VENTED HORIZONTALLY.

Note: Refer to the vent manufacturers instal-

lation instructions for variations of venting

techniques. If common venting of several units

is contemplated, it should be discussed with an

architect and the local Building Department.

Install the B-vent system in accordance with

the vent manufacturer's instructions.

SIT Millivolt Wiring Diagram

* For Wall Switch Attachment Only.

If any of the original wire as supplied must be replaced, it

must be replaced with Type AWM 200°C – 18 GA. wire.

Thermopile

TH

TP

TH

TP

Limit

Switch

Damper Switch

BK

BK

BK

BK

WHT

*

1. If any of the original wire as supplied must be replaced,

1. it must be replaced with Type AWM 200°C – 18 GA. wire.

2. 120V, 60Hz – Less than 3 amps.

BK

Junction Box

Transf.

120 V.

24 V

Factory Wired

Field Wired

BL

Electronic Wiring Diagram (Honeywell)

(Optional ON/OFF Switch Wiring)

R

BK

BL

To Opposite Side

G

W

OPT. ACCESSORY

SWITCH

120

VAC.

BK

LIMIT

SWITCH

W

Gas Valve

B

BL

OPTIONAL

ON/OFF SWITCH

OR

WALL SWITCH

R

R

IGNITER

CONTROL

PILOT

ASSEMBLY

Break

Off Tab

DAMPER

SWITCH

BK

BK

WHT BK

BK

SIT Millivolt Wiring Diagram

* For Wall Switch Attachment Only.

If any of the original wire as supplied must be replaced, it

must be replaced with Type AWM 200°C – 18 GA. wire.

Thermopile

TH

TP

TH

TP

Limit

Switch

Damper Switch

BK

BK

BK

BK

WHT

*

1. If any of the original wire as supplied must be replaced,

1. it must be replaced with Type AWM 200°C – 18 GA. wire.

2. 120V, 60Hz – Less than 3 amps.

BK

Junction Box

Transf.

120 V.

24 V

Factory Wired

Field Wired

BL

Electronic Wiring Diagram (Honeywell)

(Optional ON/OFF Switch Wiring)

R

BK

BL

To Opposite Side

G

W

OPT. ACCESSORY

SWITCH

120

VAC.

BK

LIMIT

SWITCH

W

Gas Valve

B

BL

OPTIONAL

ON/OFF SWITCH

OR

WALL SWITCH

R

R

IGNITER

CONTROL

PILOT

ASSEMBLY

Break

Off Tab

DAMPER

SWITCH

BK

BK

WHT BK

BK