11

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

Planning Installation

Safety and General

Installation

Operation

Maintenance

Troubleshooting

Parts / Accessories

Manufactured Home Installations

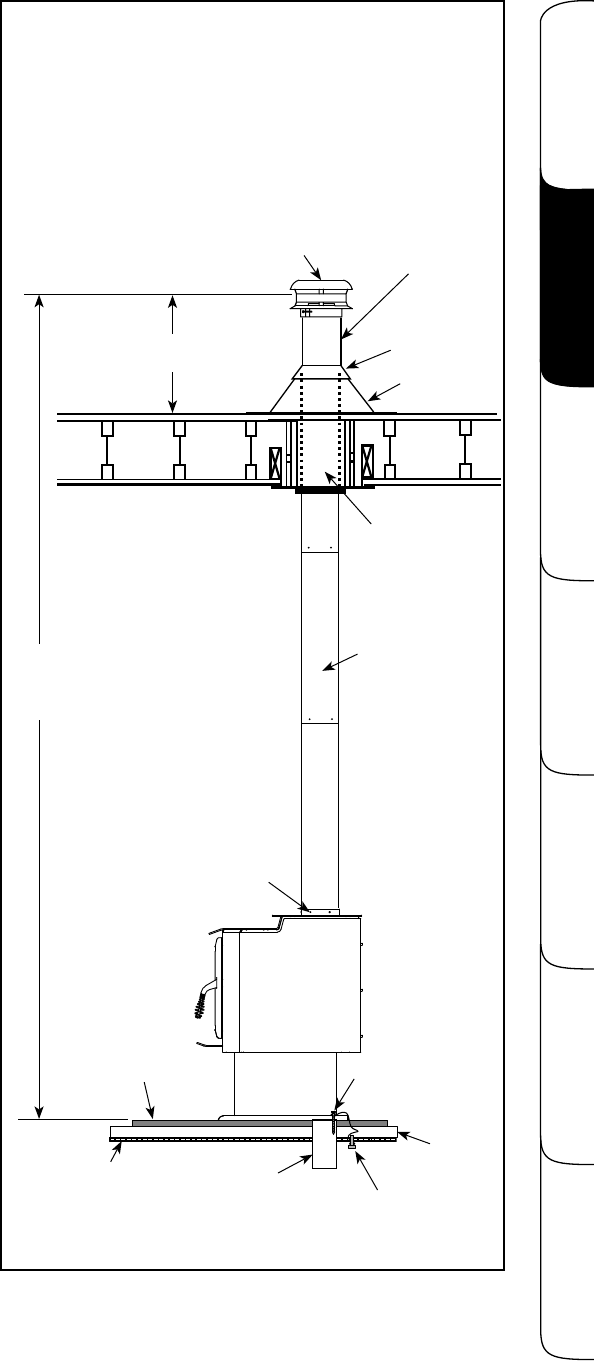

(ref. Figure 8)

This appliance is approved for installation into a manufactured

(mobile) home.

Installation should be in accordance with the Mobile Home

Construction and Safety Standard, Title 24 CFR, Part 3280 (in

Canada CAN/CSA Z240 MH), or, when such a standard is not

applicable, the Standard for Mobile Home Installations, ANSI

A225.1.

All mobile home installations require an outside air kit (see Page 27 for

ordering information). The stove must be secured to the floor and grounded

to the chassis of the mobile home (see Page 14 for detailed instructions).

WARNING: DO NOT INSTALL IN SLEEPING ROOM OF A MOBILE

HOME.

CAUTION: THE STRUCTURAL INTEGRITY OF THE MOBILE HOME

FLOOR, WALL AND CEILING/ROOF MUST BE MAINTAINED.

Approved Chimney* - Your stove is approved for use with Class A, UL

103 HT (U.S.) / ULC-S629 (Canada) Listed Residential Type and Building

Heating Appliance Chimney (HT chimney - 2100° Fahrenheit) and double

wall connector pipe from Security™ Chimneys.

Clearances to connector shall be measured from 6” flue collar. Restrictions

apply! Read instructions before installing.

YOUR CHIMNEY INSTALLATION MUST COMPLY WITH LOCAL

BUILDING AND FIRE CODES.

Termination Cap

with Spark Arrestor

Remove, if mobile

home is transported

Storm

Collar

Flashing

Support

Box

DVL Close

Clearance

Connector Pipe

Floor

Protector

3 Feet

Minimum

Double Wall Pipe

Using 6” Diameter Type L-Vent Connector Pipe

Mobile (Manufactured) Home Installation Shown

Figure 8 - Typical Installation

Minimum of

12-15’ of Flue

to achieve a

stable draft.

Fasten each stove pipe

connection with at least

3 sheet metal screws.

Mobile home installations

require a spark arrestor at the

chimney termination.

All mobile home installa-

tions require an outside

air kit (see Page 27 for

ordering information)

and the stove must be

secured to the floor and

grounded to the mobile

home chassis.

Install Outside Air

Kits per instructions

on Page 15

INSTALL VENTING SYSTEM PER VENT MANUFACTURERS

INSTRUCTIONS!

Fasten stove pipe to

flue collar using 3

sheet metal screws.

Secure to floor per

instructions on Page 14

Grounded to Steel Chassis

using a #8 AGW copper

wire or equivalent.

Chassis

Floor

Planning Installation

CHIMNEY INSTALLATION

• Install chimney as per manufacturer’s instructions. Some brands of

pipe may require removal of the spacer ring in the flue collar.

• All horizontal runs of pipe should be as short as possible and are

required by NFPA No. 211 to have an upward pitch or rise in the same

direction the smoke travels of no less than 1/4” to the linear foot. The

connector pipe must meet minimum clearances in any direction to

walls or other combustible materials. It must attach to a listed double

wall metal chimney at least 6” in diameter or to a masonry chimney

with a flue passage of at least 48 square inches.

• It is required that a chimney connector pipe not extend further than

the inner wall of the flue when it is connected to a masonry chimney

and that it either be cemented to the masonry or be installed without

cement in a thimble connected to the masonry wall. When the

connector is inserted into a thimble, the joint must be tight enough

so that it will not be dislodged in normal use. Install connector at

no less than the minimum clearances from the ceiling when using a

90-degree elbow to pass through combustible constructions.

• Chimney connector pipes should never pass through a floor, ceiling,

fire wall, partition, or combustible construction of any type unless

certain precautions are taken. The best method is to use a listed

thimble and a listed chimney in accordance with the manufacturer’s

directions. NFPA No. 211 gives approved methods for passing a flue

pipe through combustible constructions (see Page 12).