4

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

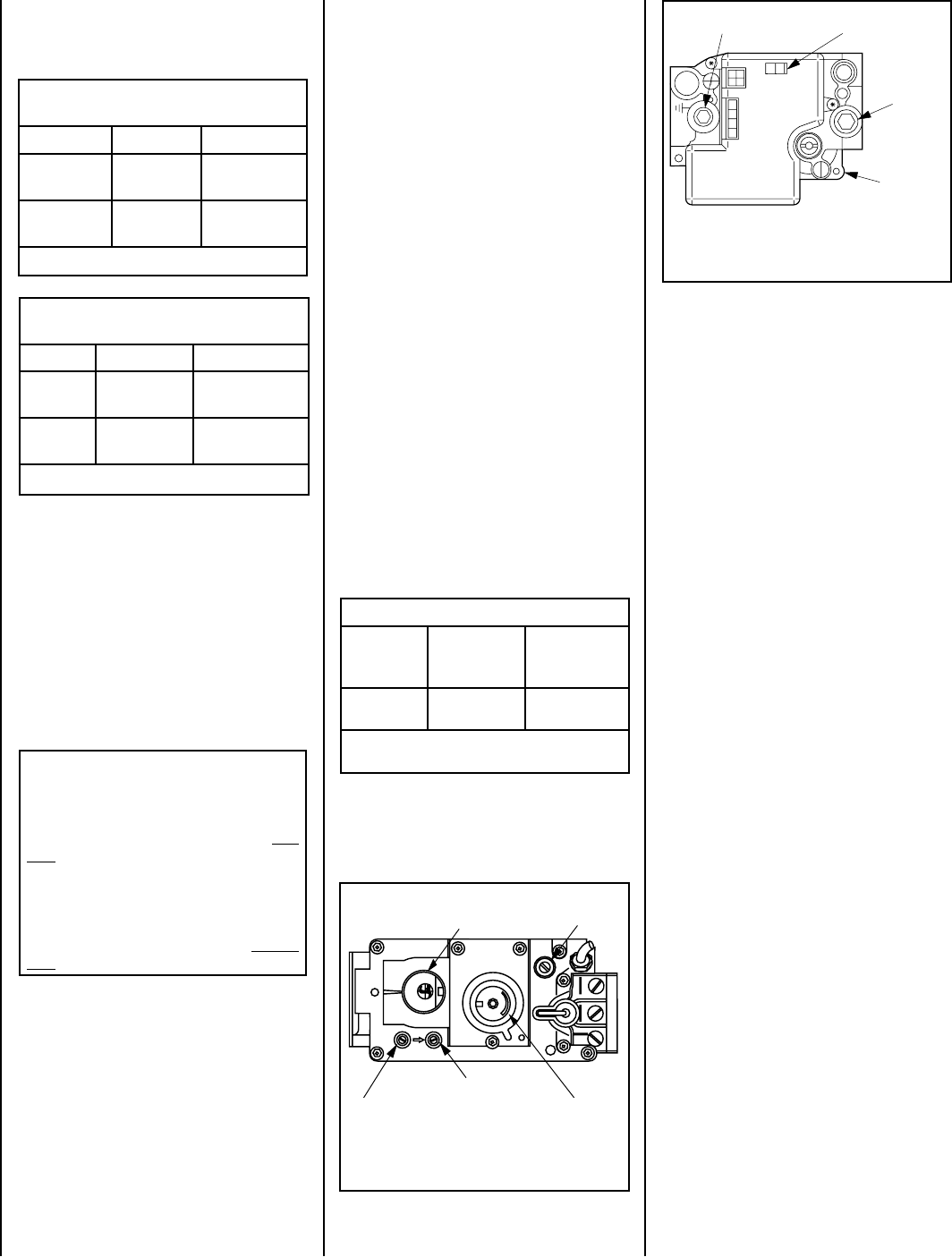

Test gauge connections are provided on the

front of the millivolt and electronic gas control

valve (identified IN for the inlet and OUT for the

manifold side). The control valves have a 3/8"

(10mm) NPT thread inlet and outlet side of the

valve (refer to Figures 1 and 2).

Propane tanks are at pressures that will cause

damage to valve components. Verify that the

tanks have step down regulators to reduce the

pressure to safe levels.

Gas Valve Diagrams

See Figure 1 for Millivolt models and Figure 2

For Electronic Models.

These appliances must not be connected to a

chimney or flue serving a separate solid fuel

burning appliance.

Manifold Gas Supply Pressure

(all models)

Fuel # Low High

Natural

Gas

(Lo) 2.2" WC

(0.55 kPa)

(Hi) 3.5" WC

(0.87 kPa)

Propane

(Lo) 6.3" WC

(1.57 kPa)

(Hi) 10.0" WC

(2.49 kPa)

Table 3

These appliances must be isolated from the

gas supply piping system (by closing their

individual manual shut-off valve) during any

pressure testing of the gas supply piping

system at test pressures equal to or less

than 1/2 psig (3.5 kPa).

These appliances and their individual shut-off

valves must be disconnected from the gas

supply piping system during any pressure

testing of that system at pressures greater

than 1/2 psig (3.5 kPa).

Orifice Sizes - Sea Level to High Altitude

(All Models)

These appliances are tested and approved for

installation at elevations of 0-4500 feet (0-1372

meters) above sea level using the standard burner

orifice sizes (marked with an "*" in Table 4 ).

For elevations above 4500 feet, contact your gas

supplier or qualified service technician.

Deration - At higher elevations, the amount

of BTU fuel value delivered must be reduced

by either:

• Using gas that has been derated by the gas

company.

• By changing the burner orice to a smaller

size as regulated by the local authorities having

jurisdiction and by the (USA) National Fuel Gas

Code NFPA 54/ANSI Z223.1 - latest edition or,

in Canada, the CAN/CSA-B149.1 codes - latest

edition.

Install the appliance according to the regulations

of the local authorities having jurisdiction and,

in the USA, the National Fuel Gas Code NFPA

54 / ANSI Z223.1 - latest edition or, in Canada,

the CAN/CSA-B149.1 - latest edition.

Flame breadth, height and width will diminish

4% for every 1,000 feet of altitude.

REQUIREMENTS FOR THE COMMON-

WEALTH OF MASSACHUSETTS

These fireplaces are approved for installation in

the US state of Massachusetts if the following

additional requirements are met:

• Install this appliance in accordance with

Massachusetts Rules and Regulations 248

C.M.R.

• Installation and repair must be done by a

plumber or gas fitter licensed in the Com-

monwealth of Massachusetts.

• The exible gas line connector used shall

not exceed 36 inches (92 centimeters) in

length.

• The individual manual shut-off must be a

T-handle type valve.

Massachusetts Horizontal Vent Requirements

In the Commonwealth of Massachusetts, hori-

zontal terminations installed less than seven

(7) feet above the finished grade must comply

with the following additional requirements:

• A hard wired carbon monoxide detector

with an alarm and battery back-up must be

installed on the floor level where the gas

fireplace is installed. The carbon monoxide

detector must comply with NFPA 720, be

ANSI/UL 2034 listed and be ISA certified.

• A metal or plastic identication plate must

be permanently mounted to the exterior of

the building at a minimum height of eight (8)

feet above grade and be directly in line with

the horizontal termination. The sign must

read, in print size no less than one-half (1/2)

inch in size, GAS VENT DIRECTLY BELOW.

KEEP CLEAR OF ALL OBSTRUCTIONS.

NEW YORK CITY, NEW YORK (MEA)

Installation of these fireplaces are approved

for installation in New York City in the US state

of New York.

Inlet Gas Supply Pressure

(all models)

Fuel # Minimum Maximum

Natural Gas

4.5" WC

(1.12 kPa)

10.5" WC

(2.61 kPa)

Propane

11.0" WC

(2.74 kPa)

13.0" WC

(3.23 kPa)

Table 2

Gas Pressure - All Models

Tables 2 and 3 show the appliances' inlet and

manifold gas pressure requirements:

Figure 2

Honeywell Electronic

Gas Valve

ON/OFF Switch

Electronic

Gas Control

Valve

Inlet

Pressure

Port

Manifold Pressure Port

OFF

IN

PSI

ON

CONTROL

IGNITER

H

I

L

O

W

HTPTHTPT

P

I

L

O

T

P

I

L

O

T

O

N

it

O

F

F

IN

OUT

HI/LO Variable

Flame Height

Adjustment

Figure 1 - SIT Millivolt Gas Valve

Manifold Pressure Tap

Inlet Pressure Tap

Pilot Adjustment

Screw

Main Gas Control Knob

OFF/PILOT/ON

Burner Orifice Sizes (all models)

Elevation

Feet (meters)

Natural

Gas

drill size (inches)

Propane

Gas

drill size (inches)

0-4500

(0-1372)

(0.125")

*

21L81 •

#41

(0.096")

*

21L82 •

Table 4

* Standard size installed at factory

• Part /Cat. Number