NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

4

IMPORTANT

Keep your house well ventilated

during the curing process. The

odor and haze emitted by the

curing process can be quite

noticeable and may set off a

smoke detector.

Lighting Millivolt Appliances

To light millivolt appliances refer to the detailed

lighting instructions found on

Page 16 (Eng-

lish) and

Page 17 (French). Millivolt appliance

lighting instructions may also be found on the

pull-out lighting instruction labels located in the

control compartment (below glass door).

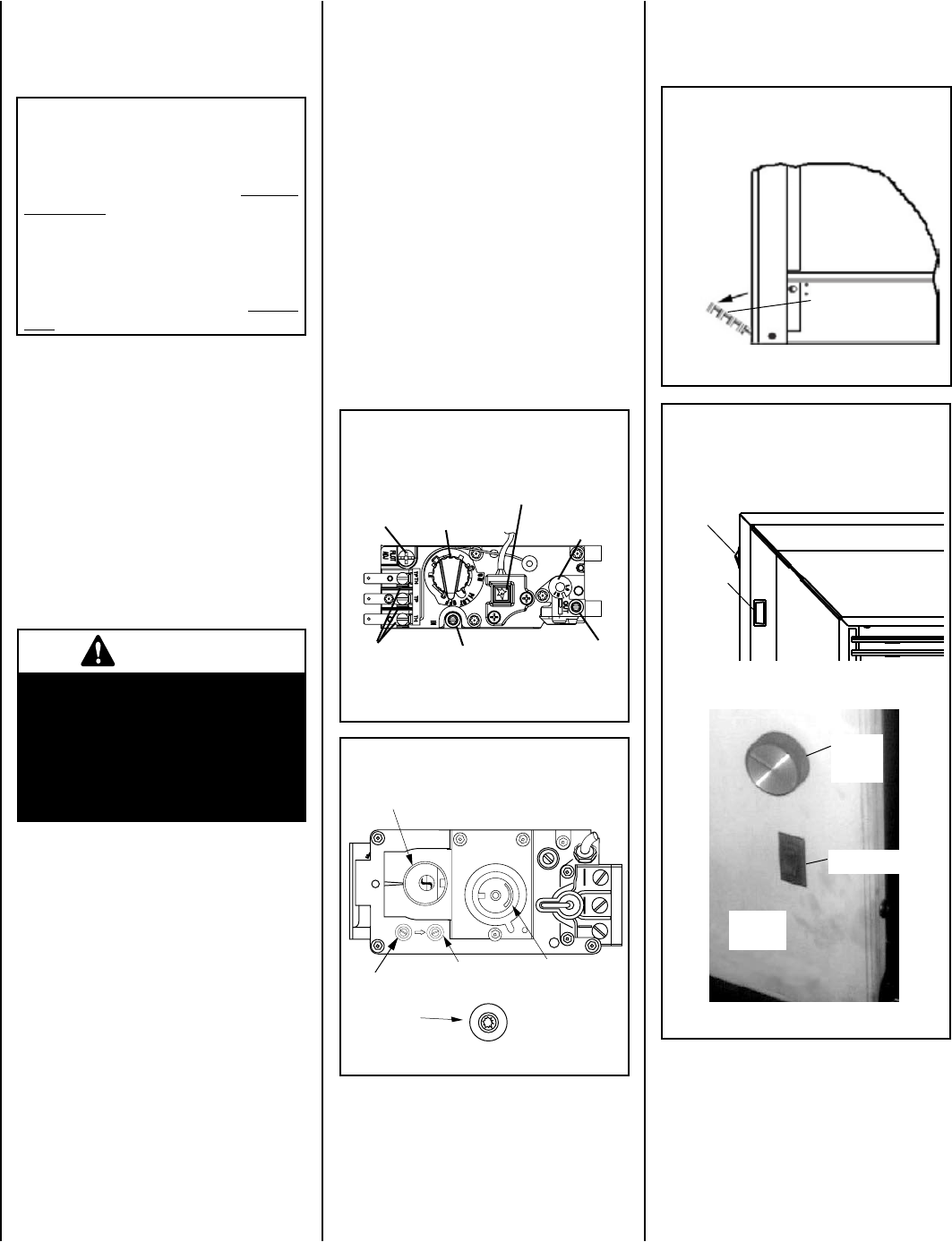

Figure 4

Burner On/Off Switch and Rheostat Location

If optional surround is installed

Control Compartment Access

Pull down hinged door to access control compartment

Pull down lower

louver (hinged)

Side View of Insert

Figure 3

Burner On/Off

Switch

Rheostat

(blower

speed

control)

Left Front

surround

Panel

Units with Beveled Surround

Units with Flat Surround

Left Front

surround

Panel

Rheostat

(blower

speed

control)

Burner On/Off

Switch

CONTROL COMPARTMENT ACCESS

Pull down hinged door to access control

compartment

(see Figure 3).

Test gauge connections are provided on the

front of the millivolt gas control valve (identi

-

fied IN for the inlet and OUT for the manifold

side). See

Figures 1 & 2.

This appliance must not be connected to a

chimney or flue serving a separate solid-fuel

appliance.

Burn-in Period

During the first few burns of these appliances

there will be some odor due to the curing of the

high temperature paint and burning off of lubri

-

cants used in the manufacturing process.

Depending on your use, the burn-in period may

take a few hours or a few days.

Do not turn on

blower during Burn-In period.

GAS CONTROLS

See Figure 3, showing how to access the

control compartment.

These millivolt appliances are fitted with a burner

ON/OFF Switch, located on the side surround

panel as shown in

Figure 4 on Page 4. Once

the pilot is lit, and valve knob is in the ON posi

-

tion, the ON/OFF switch will control the appliance

ON/OFF operation. To operate, toggle the switch

between its ON and OFF positions.

Variable Flame Height Adjustment

These millivolt appliances are equipped with a

variable gas control valve. Flame height may be

adjusted through a range between fixed low and

high settings by rotating the HI/LO knob on the

valve (see Figures 1 & 2) alternately, while the

appliances are in operation.

O

N

O

F

F

P

I

L

O

T

L

O

H

I

Figure 1

GAS CONTROL

KNOB

INLET

PRESSURE

TAP

PILOT

ADJUSTMENT

SCREW

WIRING

TERM-

INALS

OUTLET

PRESSURE

TAP

TP/TH

PIEZO

IGNITER

TH

TP

H

I

L

O

W

TPTH TP TH

P

I

L

O

T

P

I

L

O

T

O

N

it

O

F

F

IN

OUT

Figure 2

MODEL EDVI25

SIT Millivolt Gas Valve Controls

MODELS: EDVI30 & EDVI35

Honeywell Millivolt Gas Valve Controls

CONVERTIBLE

HI/LO REGULATOR

(adjusts flame height

and heat output)

GAS CONTROL

KNOB

INLET

PRESSURE

TAP

OUTLET

PRESSURE

TAP

CONVERTIBLE

HI/LO REGULATOR

(adjusts flame height

and heat output)

PIEZO

IGNITER

This appliance must be isolated from the

gas supply piping system (by closing its

individual manual shut-off valve) during

any pressure testing of the gas supply

piping system at test pressures

equal to

or less than 1/2 psig (3.5 kPa).

This appliance and its individual shut-off

valve

must be disconnected from the gas

supply piping system during any pressure

testing of that system at pressures

greater

than 1/2 psig (3.5 kPa).