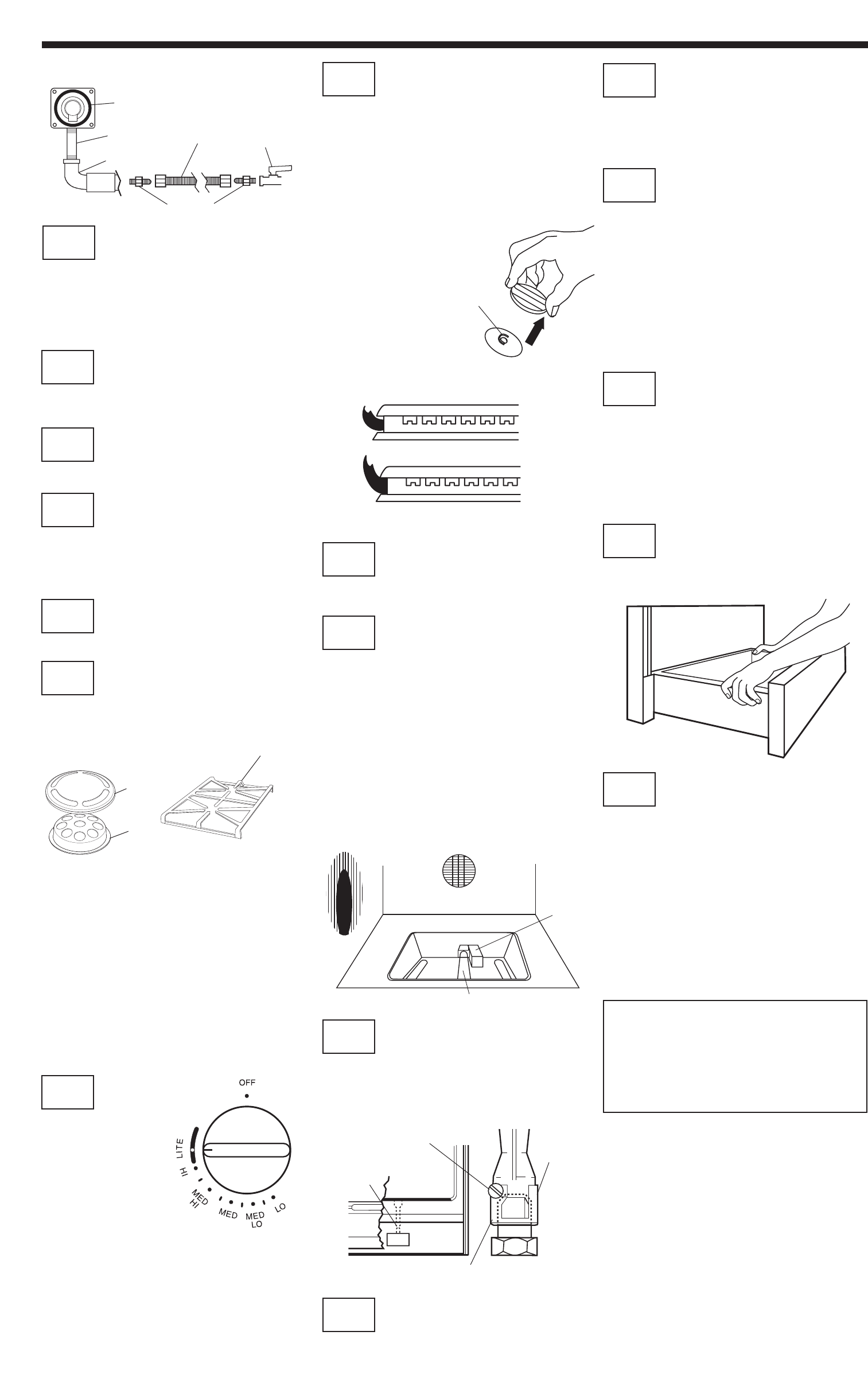

The cooktop LOW burner flame should be a steady

blue flame approximately 1/4" (0.64 cm) high. It

can be adjusted using the adjustment screw in the

center of the valve stem. The valve stem is located

directly underneath the control knob.

If the LOW flame needs to be adjusted:

a. Remove the control knob.

b. Hold the knob stem with a pair of pliers. Use

a small flat-head screwdriver to

turn the screw located in the

center of the control knob stem

until the flame is the proper

size.

c. Replace the control

knob.

d. Test the flame by

turning the control from

“LO” to “HI”, checking the

flame at each setting.

Push “CANCEL/OFF” pad. Insert oven

bottom tabs into slots in oven burner

area. Check that tabs are correctly

placed in slots. If the oven bottom is not positioned

properly, poor baking performance could occur.

Replace oven racks.

Adjust the height of top burner

flames (some models)

Panel E

Remove vent cap, cooktop burner caps

and grates from parts package. Align

notches in burner caps with pins in

burner base. Burner caps should be level when

properly positioned. Place burner grates over

burners and caps. Place vent cap over vent dome.

Plug into a grounded 3 prong outlet.

“8888” should appear in clock display.

Electronic Ignition System —

Initial lighting and gas flame adjustments.

Cooktop and oven burners use electronic ignitors

in place of standing pilots. When the cooktop

control knob is turned to the “LITE” position, the

system creates a spark to light the burner. This

sparking continues as long as the control knob is

turned to “LITE”.

When the oven control is turned to the desired

setting, a glow bar heats up bright orange and

ignites the gas. No sparking occurs and the glow

bar remains on while the burners operate.

Check the

operation of

the cooktop

burners. Push in and

turn each control knob

to the “LITE” position.

The flame should light

within 4 seconds. The

first time a burner is

lighted it may take

longer than 4 seconds

to light because of air in

gas line.

If burners do not light properly, turn cooktop control

knob to the “OFF” position. Check that the power

supply cord is plugged in and the circuit breaker or

fuse has not blown. Check that the gas shutoff

valves are set to the “OPEN” position. Repeat Step

22. If a burner does not light at this point, contact

your KitchenAid dealer or authorized service

company for assistance.

Check the operation of the oven

burner. Push the “BAKE” pad and

“350˚F” will appear in the temperature

display. Press the “Start” pad. “LO” will appear in

the display; then “170˚F.” The oven burner should

light in 50 to 60 seconds. This delay is normal. The

oven safety valve requires a certain time before it

will open and allow gas to flow.

Electric ignitors are used to light the oven and broil

burners.

Do not insert any object into the opening of the

protective shield that surrounds the ignitor.

Do not clean the area.

Check the oven burner for proper flame.

This flame should have a 1/2" (1.3 cm)

long inner cone of bluish-green, with an

outer mantle of dark blue, and should be clean and

soft in character. No yellow tips, blowing or lifting of

flame should occur.

Remove the oven rack. Remove the

oven bottom and place it on a protected

surface.

burner

grate

vent

cap

vent

dome

ignitor

oven

rear

oven burner

If the oven flame needs to be adjusted,

locate the air shutter near the center

rear of range. Loosen the locking screw

and rotate the air shutter until the proper flame

appears. Tighten locking screw.

oven burner

air shutter

location

locking screw

oven burner

air shutter

— rotate to

adjust for

proper

flame

brass orifice

hood (nut)

Check the operation of the

oven broil burner. Close the oven door.

Press the “BROIL” pad. “500˚F” will

appear in the temperature display. Press the “Start”

pad. The oven broil burner should light in 50 to 60

seconds. This delay is normal. The oven safety

valve requires a certain time before it will open and

allow gas to flow. The first time broil burner is

lighted, it may take longer to light because of air in

gas line. The first few times burner is used sparks

may appear. This is normal.

NOTE:

Oven door must be shut for broil burner to

operate.

Look through oven window to check

broil burner for proper flame. The flame

should have a uniform, light blue

appearance around the burner surface. No yellow

tips, blowing or lifting of the flame should occur.

NOTE:

The first few times the broil burner is used,

yellow sparks may appear in the flame. This is

normal and will stop after burner has been used a

few times.

Press the “CANCEL/OFF” pad. If the

broil burner flame needs adjustment,

contact your KitchenAid dealer or

authorized service company for assistance.

Insert storage drawer into slide rails

on sides of drawer opening. Lift front

of drawer slightly and push firmly to

close drawer.

L.P. gas conversion

No attempt shall be made to convert the range

from the gas specified on the model/serial rating

plate for use with a different gas without consulting

the servicing gas supplier. An L.P. Gas Conversion

Kit is included in your literature package.

high flame

low flame

adjustment

screw

To get the most efficient use from

your new range, read your Use and

Care Guide. Keep Installation

Instructions and Guide close to

range for easy reference.

Top burner flame appearance:

20.

24.

29.

25.

26.

21.

22.

23.

27.

28.

30.

31.

32.

1/2" (1.3 cm) flare union adapters

pressure regulator

and valve assembly

flexible

connector

3" (7.6 cm)

connector

90° elbow

Assemble the flexible connector from

the gas supply pipe to the pressure

regulator, located in the lower left side

of the storage drawer area, in this order: shutoff

valve, 1/2" (1.3 cm) flare union adapter, flexible

connector, 1/2" (1.3 cm) flare union adapter. Seal

all openings in floor or wall wherever range is

installed.

Use pipe-joint compounds appropriate

for use with L.P. gas to seal all gas

connections. If flexible connectors are

used, be certain connectors are not kinked.

All connections must be wrench-tightened.

manual

shutoff valve

Open the shutoff valve in the gas

supply line. Wait a few minutes for the

gas to move through the gas line.

Test for gas leaks. Leak testing shall be

conducted according to the following

instructions: Test all connections by

brushing on an approved non-corrosive leak-

detection solution. Bubbles will show a leak.

Correct any leak found.

16.

17.

18.

19.