Panel B

The cooktop sides of the slide-in range fit over

the cutout edge of your countertop.

If you have a square finish (flat) countertop and

the opening width is 30" (76.2 cm), no

countertop preparation is required.

Formed front-edged countertops: Must have

molded edge shaved flat 1/2" (1.3 cm) from

each front corner of opening.

Tile countertops may need trim cut back

1/2" (1.3 cm) from each front corner and/or

rounded edge flattened.

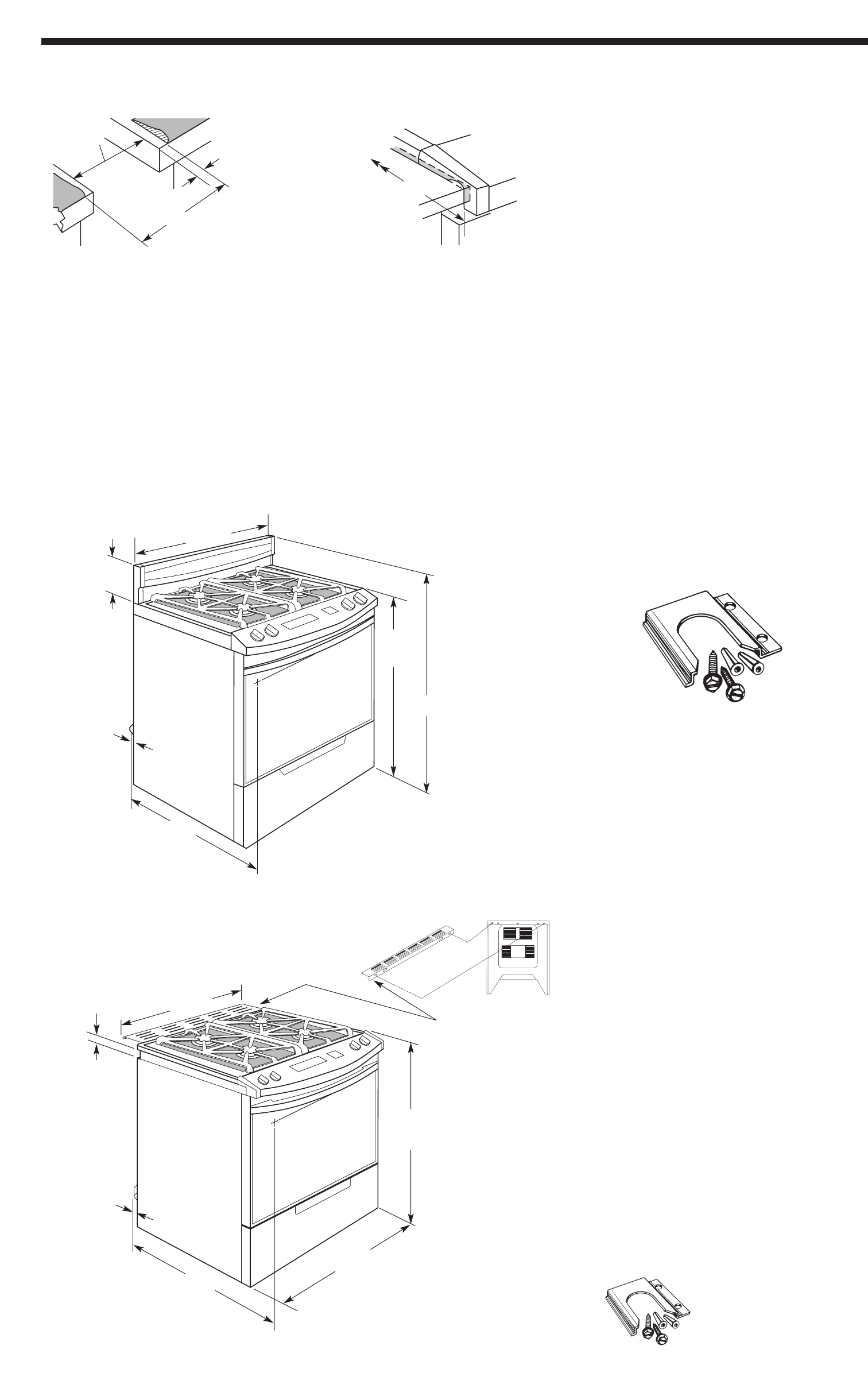

Product dimensions

Cooktop sides of range fit over

edges of countertop opening.

Slide-in ranges:

countertop preparation

Freestanding Range

If countertop opening width is greater than

30" (76.2 cm), adjust the 1/2" (1.3 cm) dimension.

Countertop must be level. Place level on

countertop, first side to side; then front to back.

If countertop is not level, range will not be level.

Oven must be level for satisfactory baking

conditions.

Formed or tiled countertop

trimmed 1/2" (1.3 cm) back

at front corners of

countertop opening.

30-7/8"

(78.4 cm)

1/2"

(1.3 cm)

Slide-in Range

30"

(76.2 cm)

opening

width

8-1/4"

(21 cm)

1"

(2.54 cm)

spacer

30" (76.2 cm)

range width

44-3/8"

(112.7 cm)

36-1/8"

(91.8 cm)

cooktop

height

28"

(71.1 cm)

depth

with

handle

1-1/2"

(3.8 cm)

1"

(2.54 cm)

spacer

30" (76.2 cm)

rear vent width

36-1/8"

(91.8 cm)

cooktop

height

28"

(71.1 cm)

depth

with

handle

Mobile home installation

The installation of this range must conform to the

Manufactured Home Construction and Safety

Standards, Title 24 CFR, Part 3280 (formerly the

Federal Standard for Mobile Home Construction and

Safety, Title 24, HUD, Part 280); or when such

standard is not applicable, the Standard for

Manufactured Homes Installations (Manufactured

Home Sites, Communities and Setups), ANSI

A225.1/NFPA 501A*, or with local codes.

In Canada, the installation of this range must conform

with the current standards CAN/CSA-Z240 — latest

edition**, or with local codes.

When this range is installed in a mobile home, it must

be secured to the floor during transit. Any method of

securing the range is adequate as long as it conforms

to the standards listed above.

Copies of the standards listed may be obtained from:

*

National Fire Protection Association

One Batterymarch Park

Quincy, Massachusetts 02269

**CSA International

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

Tools needed for

installation:

The floor anti-tip bracket must

be installed. To install the anti-tip

bracket shipped with the range,

see Panel D and the anti-tip

bracket template.

Anti-tip bracket:

Assemble the required tools and parts before starting

installation. Read and follow the instructions provided

with any tools listed here.

• level

• Phillips scewdriver

• flat-blade screwdriver or 5/16”"(7.9 mm) nut driver

• 3/8" ( 9.5 mm) ratchet

• adjustable wrench

• pliers

• hammer

• measureing tape or ruler

• hand or electric drill

wood floor: 1/8" (0.3 cm) drill bit

concrete/ceramic floor: 3/16" (0.48 cm) carbide-

tipped masonry drill bit

• L.P. gas conversion requires: pin pick up (claw

attachment)

• 5/16" nut driver

30"

(76.2 cm)

width

Parts supplied for

installation:

(Bracket must be securely mounted to sub-floor.

Thickness of flooring may require longer screws to

anchor the bracket to sub-floor.)

anti-tip

bracket

2 screws

(#10 x 1-1/2")

2 plastic

anchors

25"

(63.5 cm)

IMPORTANT:

Rear vent must not

be obstructed for

proper ventilation on

all slide-in models.

See Step 7, Panel D.

• burner grates and caps

• vent cap

• L.P. conversion orifice spud kit:

1 – 0.95 mm (0.0374") cooktop (blue)

2 – 0.67 mm (0.0264") cooktop (black)

1 – 1.05 mm (0.0413") cooktop (green)

1 – #65 (0.0350") broil burner