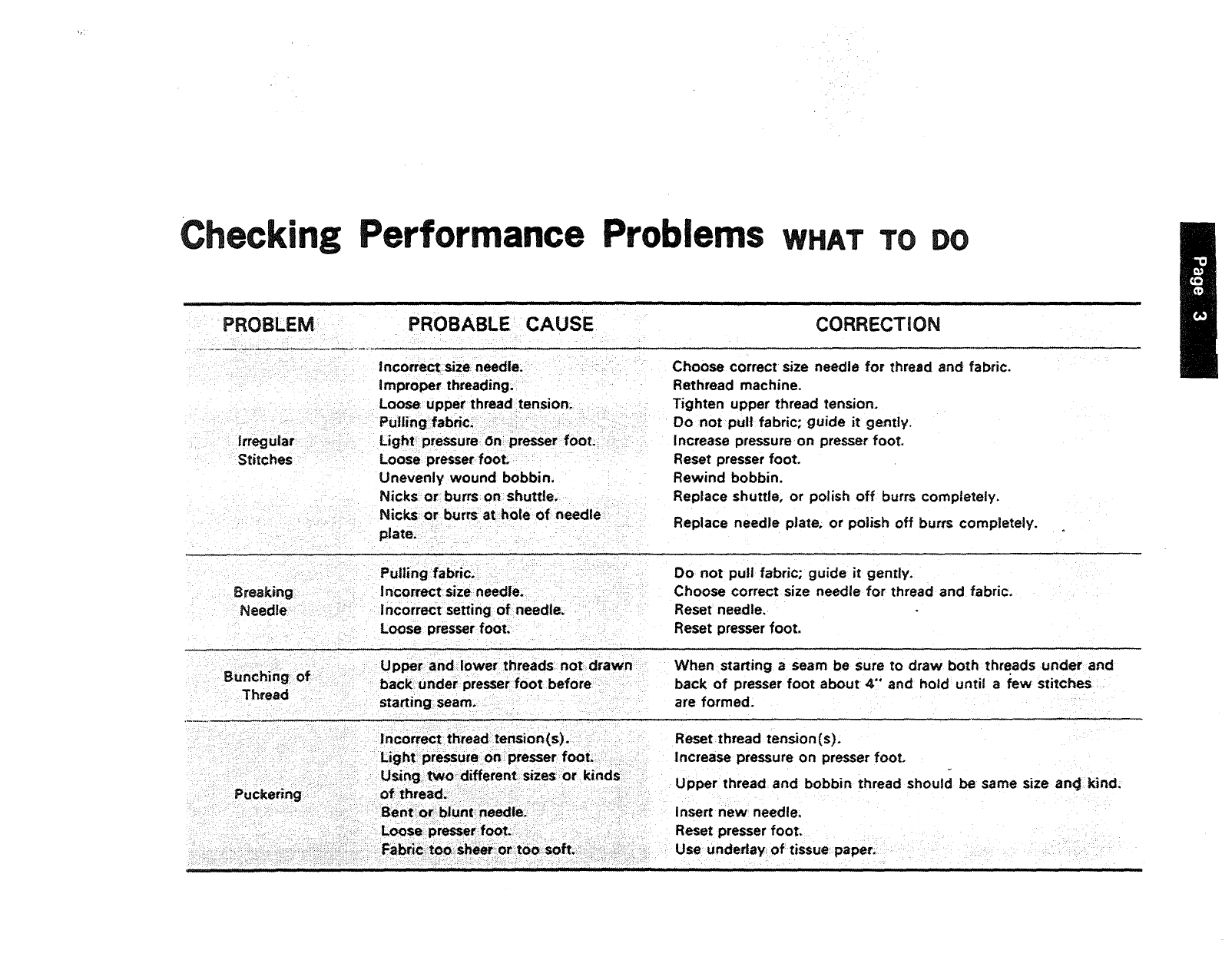

Checking Performance Problems WHATTO DO

i i i i

PROBLEM PROBABLE CAUSE CORRECTION

|rregular

Stitches

Incorrect size needle.

improper threading;

Light pressure on presser foot.

Loose presserfoot,

Unevenly wound bobbin,

Nicks or burrs on shuttle,

Nicks or burrs at hole of needle

plate, i!; _

Choose correct size needle for thread and fabric.

Rethread machine.

Tighten upper thread tension.

Do not pull fabric; guide it gently.

Increase pressure on presser foot.

Reset presser foot.

Rewind bobbin.

Replace shuttle, or polish off burrs completely,

Replace needle plate; or polish off burrs completely.

Breaking

Needle

Pulling fabric.

Incorrect size needle.

Incorrect setting of needle.

Loose presser foot;

Do not pull fabric; guide it gently.

Choose correct size needle for thread and fabric.

Reset needle.

Reset presserfoot,

Bunching of

Thread

backunder presser foot before

starting; seam.

lnco, ectthreadltensiOn(s).....

Light pressure on presser foot:

Using: twodifferent sizes or kinds

of thread.;

Bent: or blunt needle.

Loose presser: foot_:

Fabri¢! too::sheer!or tOO..soft; _

Hi i i i

When starting a seam be sure to draw both threads under and

back of presser foot about 4" and hold until a few stitches

are formed.

Reset thread tension(s).

Increase pressure on presser foot.

Upper thread and bobbin thread should be same size ancj kind.

insert new needle;

Reset presser foot.

Use underlay of tissue paper.

J i i i i ii ii = i r i .