364861-UIM-H-0712

16 Johnson Controls Unitary Products

Twinning Operation

Heating - On a call for heat (W signal) from the wall thermostat, both

furnaces will start the ignition sequence and the burners on both fur-

naces will light. About thirty seconds after the burners light, the blowers

on both furnaces will come on in heating speed. When the thermostat is

satisfied, the burners will all shut off and, after the selected blower off

delay time, both blowers will shut off at the same time. The twinning

control ensures that both blowers come on and shut off at the same

time.

Cooling - On a call for cooling (Y signal) from the wall thermostat, both

furnace blowers will come on at the same time in cooling speed. When

the thermostat is satisfied, both blowers will stay on for 60 seconds,

then will shut off at the same time.

Continuous Fan - On a thermostat call for continuous fan (G signal),

both furnace blowers will come on at the same time in cooling speed

and will stay on until the G signal is removed.

STAGING

This control can also be used along with a two-stage wall thermostat to

stage two twinned furnaces, making them operate like a single two-

stage furnace. This allows only one furnace to supply heat during times

when the heat output from one furnace is sufficient to satisfy the

demand. When one duct system is used for two furnaces, it is neces-

sary that the two blowers operate in unison. The twinning function of

this board ensures that both blowers turn on and off simultaneously,

and operate on the same blower speed. Even when only one furnace is

supplying heat, both furnace blowers must run.

The twinning feature of this board can also be used for staging of two

furnaces. With this feature, a single wire is connected between the

TWIN terminal on one furnace board to the TWIN terminal on the sec-

ond furnace board. The board then communicates the blower status

from one furnace to the other along this wire. This communication

makes the second furnace blower come on at the same time, and on

the same speed, as the first furnace blower. To ensure stable communi-

cation, the common terminal of each control must be connected.

Staging Instructions

Connect the control wiring as shown in Figure 22.

1. Connect the low voltage wiring from the wall thermostat to the ter-

minal strip on the control board of Furnace #1. For staging applica-

tions, the wire from thermostat W1 is connected to the W

connection on the board on Furnace #1. The wire from thermostat

W2 is connected to Furnace #2 through a separate relay, as

described below.

2. Connect a wire from the TWIN terminal of Furnace #1 to the TWIN

terminal of Furnace #2.

3. Install a separate 24V relay as shown in the diagram below. Use of

this relay is required, as it ensures that the transformers of the two

furnaces are isolated, thus preventing the possibility of any safety

devices being bypassed.

4. Connect the 24V common between furnace #1 and furnace #2.

Staging Operation

Heating - On a call for first-stage heat (W1 signal) from the wall thermo-

stat, Furnace #1 will start the ignition sequence and the burners will

light. About thirty seconds after the burners light, the blowers on both

furnaces will come on in heating speed. When the thermostat is satis-

fied, the burners will shut off and, after the selected blower off delay

time, both blowers will shut off at the same time. On a call for second

stage of heat, the burners of Furnace #2 will also light and both blowers

will run. The twinning control ensures that both blowers come on and

shut off at the same time.

Cooling - On a call for cooling (Y signal) from the wall thermostat, both

furnace blowers will come on at the same time. When the thermostat is

satisfied, both blowers will stay on for 60 seconds, then will shut off at

the same time.

Continuous Fan - On a thermostat call for continuous fan (G signal),

both furnace blowers will come on at the same time in cooling speed

and will stay on until the G signal is removed.

SECTION VII: CONDENSATE PIPING AND

FURNACE VENTING CONFIGURATION

CONDENSATE DRAIN LOCATION

As shipped from the factory:

• For all 040, 060, & 080K input furnaces the main drain is plumbed

through the casing right-side opening when viewed from the front

of the furnace.

• For all 100, 120, & 130K input furnaces the main drain is plumbed

through the casing left-side opening when viewed from the front

of the furnace.

The condensate hoses must slope downwards at all points.

When drain hose routing changes are required (shown in Figures 25 -

28), be sure to cap all un-used openings.

If rerouting hoses - excess length should be cut off so that no sagging

loops will collect and hold condensate - which will cause the furnace to

not operate.

No hose clamps are needed for connecting to the condensate pan.

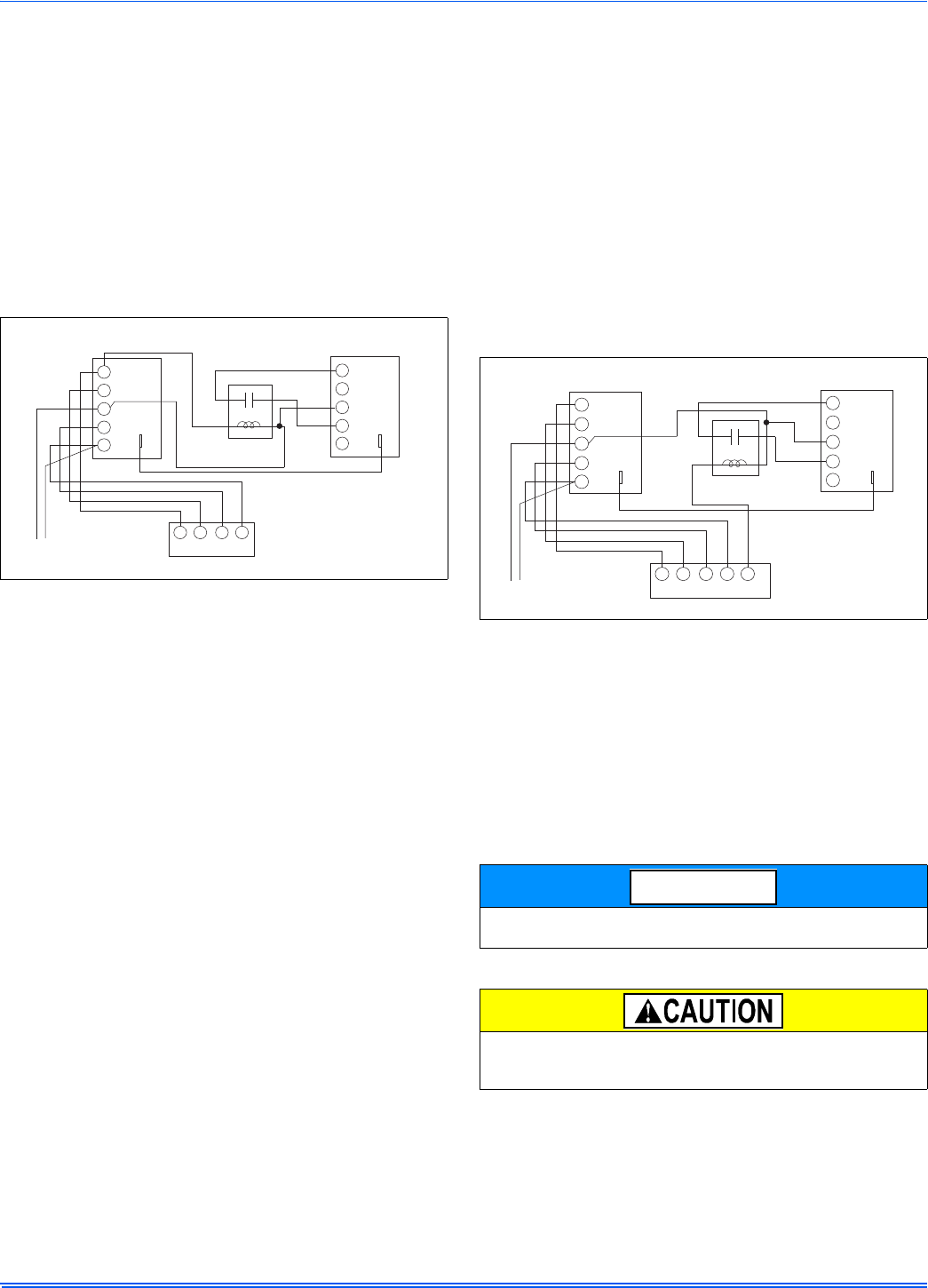

FIGURE 21: Twinning Wiring Diagram

W

G

C

R

Y

TWIN

TOA/C

WALL THERMOSTAT

WG

R

Y

ISOLATION

RELAY

FURNACE 2

CONTROL BOARD

W

G

C

R

Y

TWIN

FURNACE 1

CONTROL BOARD

FIGURE 22: Staging Wiring Diagram

The Figures 25 - 28 show the condensate drain arrangement for the

various possible furnace and vent blower positions.

The furnace condensate pan is self priming and contains an internal

trap to prevent flue gas leaking. Do not install an external condensate

trap.

W

G

C

R

Y

TWIN

TOA/C

WALL THERMOSTAT

W1 G

R

Y

ISOLATION

RELAY

FURNACE 2

CONTROL BOARD

W

G

C

R

Y

TWIN

FURNACE 1

CONTROL BOARD

W2

NOTICE