page 5

TOOL ASSEMBLY

WARNING!

To reduce the risk of injury, always unplug vacuum

cleaner before attaching or removing accessories

or making adjustments. Use only specifically

recommended accessories. Others may be

hazardous.

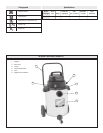

Assembling Dolly (Fig. 1)

Assemble as shown in the diagram. You will need a hammer and a

Phillips screwdriver.

1. Place wheels on rear frame (B) by tapping in the axle (C), fitting the

wheel (D) on the axle and tapping a cap nut (E) on with a hammer.

2. Insert caster socket (G) into front frame (F) and secure it with the

phillips screw (I).

3. Align front frame (F) and rear frame (B) so that they fit together and

fit lip of tank (J) into the grooves in front and rear frames.

4. Secure frame (B and F) to the tank by placing the hex bolts (K)

through the holes in dolly and securing them with nut (N) and washer

(M) as shown.

5. Insert caster (H) into caster socket (G) and push down until caster

snaps into place.

Installing Handle (Fig. 2)

You will need either a flat blade screwdriver or a socket driver and a

wrench or a pair of pliers.

1. Place dolly handle between tank and side handle on either side of

the tank.

2. Fasten tightly with slotted hex head screws.

Fig. 2

Fig. 1

A

E

D

C

G

F

H

I

B

J

L

M

N

K

OPERATION

Vacuuming Wet Materials (Fig. 3)

When vacuuming wet materials, either the filter cartridge or the

foam sleeve is required. Remove all dry pick-up filters. A float valve

shuts off suction when the tank is full (Fig. 3). If you are vacuuming a

large amount of liquid, the filter cartridge can become saturated and a

mist can appear from the exhaust port. If this happens, dry the filter by

running the vacuum (without picking up anything) for 10

minutes.

WARNING!

If the float is clean and moves freely and the

suction does not shut off when tank is filled (you

will be able to see water in the exhaust port),

send motorhead to the nearest

MILWAUKEE

service facility for repair.

Fig. 3

float

float cage