WLM2203A-XXPage4of4

PLACING INTO SERVICE

AIR AND LUBRICATION REQUIREMENTS

Filteredair willhelpextendthe lifeofthepump, allowingthepumpto op-

erate more efficiently and yield longer service life to moving parts and

mechanisms.

• Installanairlinefiltertoprovidegoodqualitycleananddryair.Install

it up stream from the regulator.

• Use an airregulator ontheair supplyto control thepump cyclerate.

Install the regulator as close as possible to the pump.

• Inmostinstallations,lubricationisnotrequired.Ifthepump needsto

havelubrication,installanairlinelubricatorandsupplyitwithagood

grade of non-detergent oil or other lubricant compatible with Nitrile

seals and set at a rate not to exceed one drop per minute.

INSTALLATION

• Mount and secure the pump as required for the application.

• Attach a ground wire from the pump ground screw to a suitable

ground.

• Connectafluidhosetothepumpoutlet.Inmostcasesapipesealant

should be used on thread connection. Tighten all fittings. Use cau-

tion not to damage threads.

OPERATION

START-UP

1. Turn the air regulator to “0” pressure setting.

2. Immerse the lower pump end into the material.

3. Open the dispensing device.

4. Startthepump cyclingslowly byraisingthe pressureto 1.4- 2.1bar

(20 - 30 p.s.i.).

5. Close the dispensing device. Allow the pump to stall and build line

pressure.Check foranyleaks andtightenfittingsas needed.Adjust

pressure as required for the application.

SHUTDOWN

• Disconnecttheairsupplyfromthepumpifitistobeinactiveforafew

hours. Open the dispensing device to relieve line pressure.

SERVICE

PUMP DISASSEMBLY / REASSEMBLY

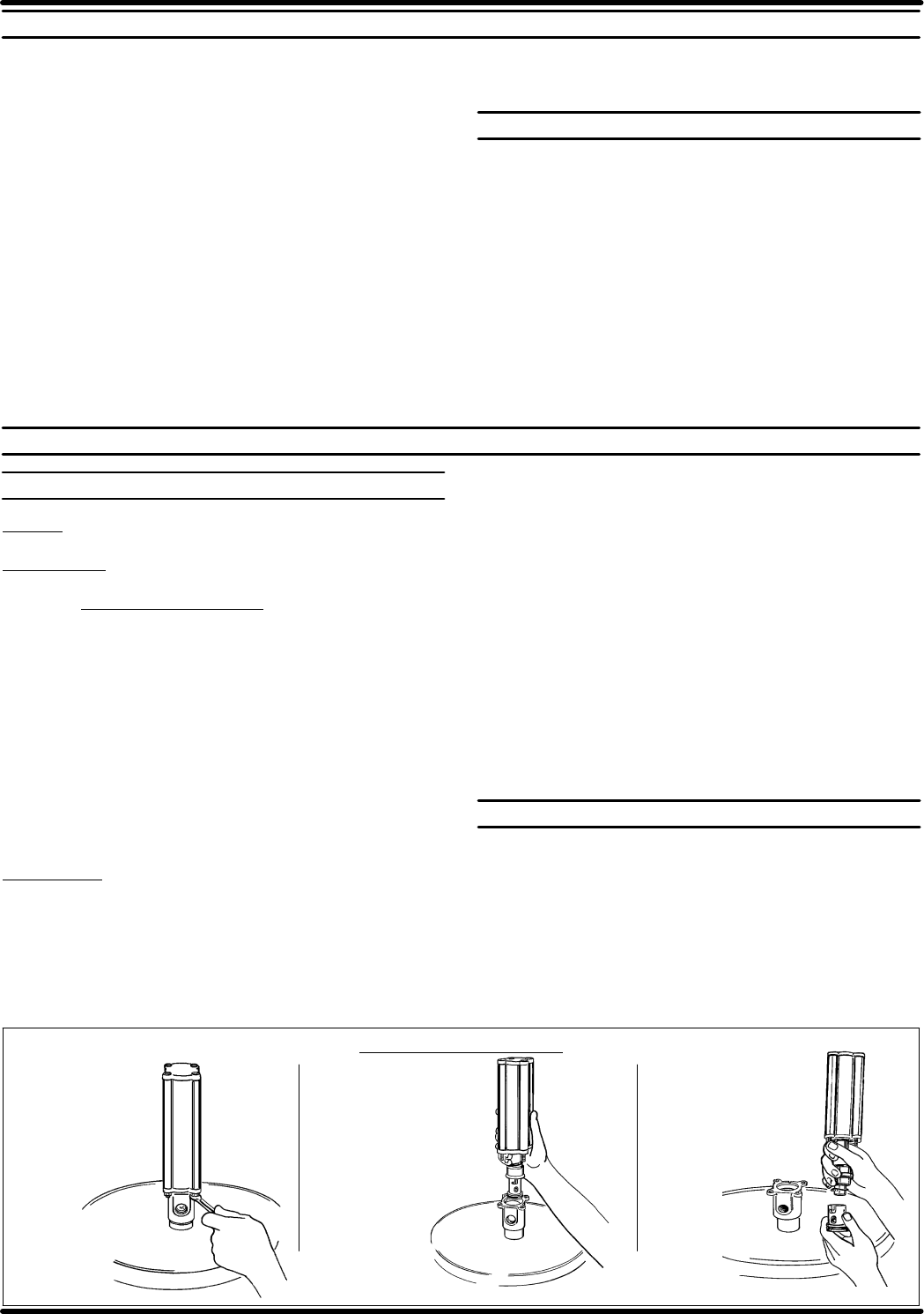

NOTICE: The unique design of this pump allows for quick basic pump

service without total removal from the drum (refer to the views below).

DISASSEMBLY

- Allthreadsarerighthand.Refertofigure2.These

proceduresarefortheinstallationofrepairkitparts.Disconnectair

supply andrelieve all systempressure

prior to servicing. Carefully

removetheparts,inspectpartsfordamage,nicksorexcessivewearand

determine if any parts will need replacement.

Follow the three disassembly steps in the detail views below and place

the pump on a clean bench.

1. Remove (1)bolts.Remove(18)packing, (17)bushingand(16) “O”ring.

2. Remove (36) adapter, releasing (10) muffler.

3. Grasp the (11) cylinder and remove the (20, 14) piston assembly.

4. Remove(15)lowercap and(3)trackgasket. Remove(12)retaining

ring and (48) washer, then pull (14) piston off (20) piston rod.

5. Remove(2) cap and (3) track gasket. Push onthe large o.d. end of

the(7)spooltoremovethe(4)sleeve.Grabthenoseof(7)spooland

pull out. Repeat for other sleeve and spool.

REASSEMBLY

- Thoroughly clean and lubricate all seals and

bores with Shell Gadus S2U1000 upon assembly. Replace allsoft

parts with new ones included in the repair kit.

Note: Refer to the illustration (figure 2) for “U” cup lip seal direction.

1. Replace the seals on both the (7) spools and (4) sleeves.

2. Locate the valve chamber on the (11) cylinder where the 3/8’’ dia.

hole is locatedand installone of the(4) sleeves.Insert the(7) spool

from the opposite end. Next, install the remaining sleeve and spool.

3. Replace the (3) track gasket and install (2) cap.

4. Replacethe(13)piston “U”cups(refertofigure 2forproper orienta-

tion).Replace the (19)“O”ringand assemble(14) pistonto(20)pis-

ton rod and retain with (48) washer and (12) retaining ring.

5. Installthe (20, 14) pistonassembly using great care tocollapse the

outer lip of the second “U” cup, allowing it to slip into the cylinder.

6. Replacethe (3) track gasket andinstall the(15) cap. Installthe (16)

“O” ring ontothe piston rod, replace(17) bushing and (18)packing.

7. Replace the (25) “O” ring and re-attach the (24) inner check.

8. Slidethe pump assembly back into the (26)base / lowerpump sec-

tion.Pressthesectionstogetherandaligntheairinletandpumpout-

letasrequiredand replacethefour(1)boltsand(27) nuts(tighten to

9 Nm (79.7 in. lbs).

TROUBLE SHOOTING

If the pump will not cycle or will not deliver material.

• Becertaintocheckfornon-pumpproblemsincludingkinked,restric-

tiveorpluggedinlet/outlethoseordispensingdevice.Depressurize

the pump system and clean out any obstructionsin the inlet / outlet

material lines.

• Check all seals, including track gaskets.

• Check direction of “U” cup lips.

C) Unlock the (24) inner

check from the pistonrod.

Figure 5

Figure 4

B) Grasp the lower motor cap

and pull out the motor and

upper section of the lower

section.

PUMP DISASSEMBLY DETAIL

Figure 3

A) Remove the four

nuts from the base

of the Air Motor.

PN 97999-865