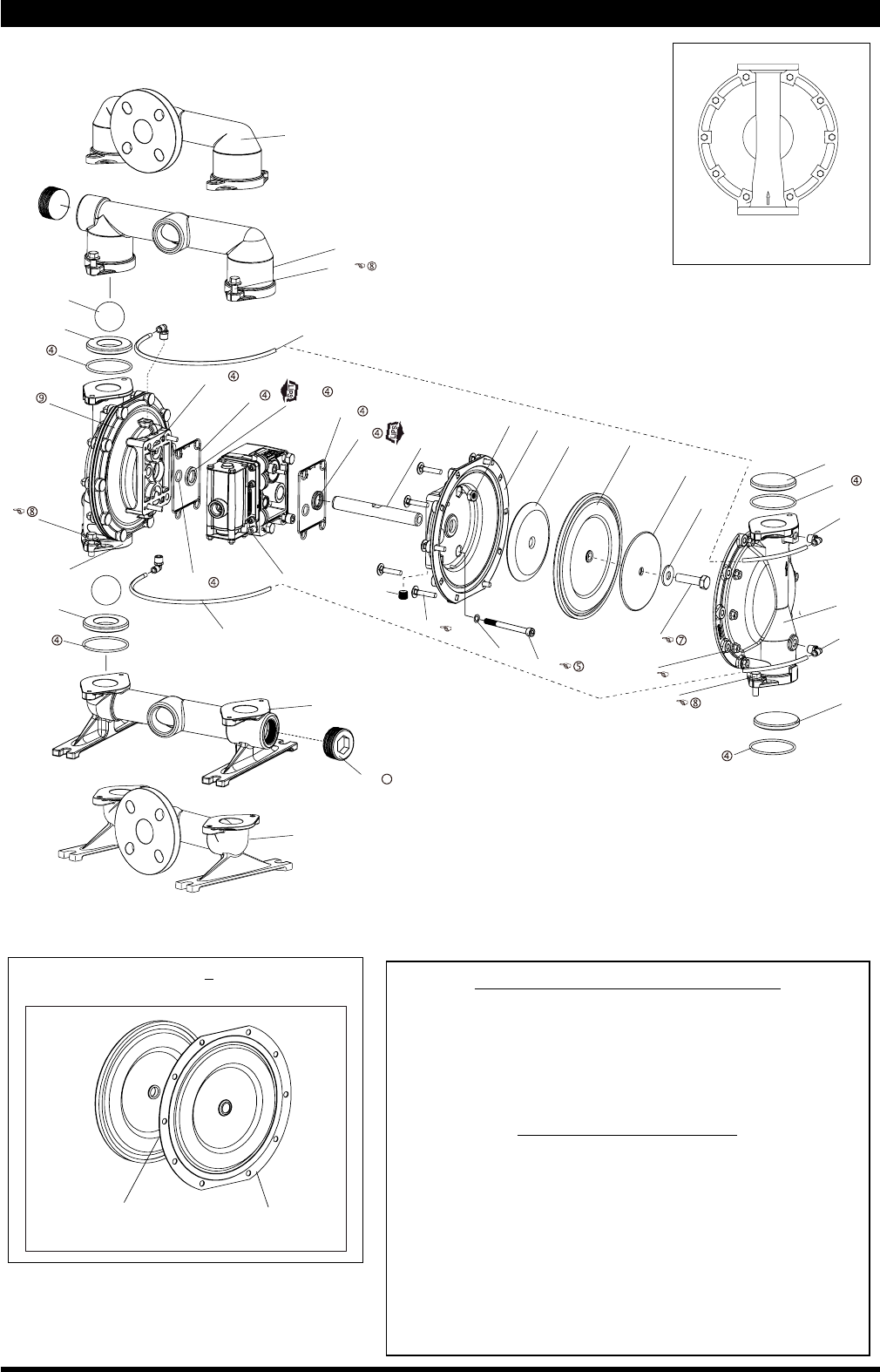

PH15F-XXX-XXX-X (en) Page 5 of 8

15

181

70

1

68

26

144

175

43

78

27

131

180

21

21

19

22

61

26

78

60

63

60

5

69

195

19

70

144

126�

77

77

76

15a

76

9

14

29

26

6

8

19

19

(models PH15F-AXX-XXX

and PH15F-BXX-XXX)

(model PH15F-FXX-XXX)

2

61

(model PH15F-FXX-XXX)

ASSEMBLY TORQUE REQUIREMENTS

NOTE: DO NOT OVERTIGHTEN FASTENERS.

ALL FASTENERS ARE METRIC.

(14) Cap Screws 50-55 Ft-Lbs (67.8 - 74.6 Nm).

(26) Manifold Screws 20 - 25 Ft-Lbs (27.1- 33.9 Nm).

(27) Fluid Cap 15-20 Ft-Lbs (20.3 - 27.1 Nm).

(131) Screws 12-17 Ft-Lbs (16.3 - 23 Nm).

LUBRICATION / SEALANTS

Apply Lubriplate FML-2 grease to all “O” rings, “U” cups and mating parts.

Apply Loctite® 262™ to threads at assembly.

Apply PTFE tape to threads at assembly.

Apply Loctite 271™ to threads.

Apply anti-seize compound to threads and bolt and nut flange heads

which contact pump case when using stainless steel fasteners.

Apply 96998 3/8” wide x 1/8” thick Joint Sealant (aproximately 27.12”

long) to air cap (item 68 only) diaphragm bead groove. Use ONLY 1

wrap of sealant. DO NOT overlap seam. Fill seam with heavy duty an-

aerobic pipe sealant. Seam to be located between bolt positions 1 and

3 (refer to “Torque Sequence” diagram).

Lubriplate FML-2 is a white food grade petroleum grease.

PARTS LIST / PH15F-XXX-XXX-X FLUID SECTION

View for PH15F-XXX-XXT-X (PTFE diaphragm)

conguration only.

(Santoprene)

8

(PTFE)

7

FOR THE AIR MO-

TOR SECTION, SEE

PAGES 6 & 7.

Torque Sequence

Figure 2

3

2

7

5

1

8

10

6

4

9