Page 7 of 8PE10P-X-X-A0S

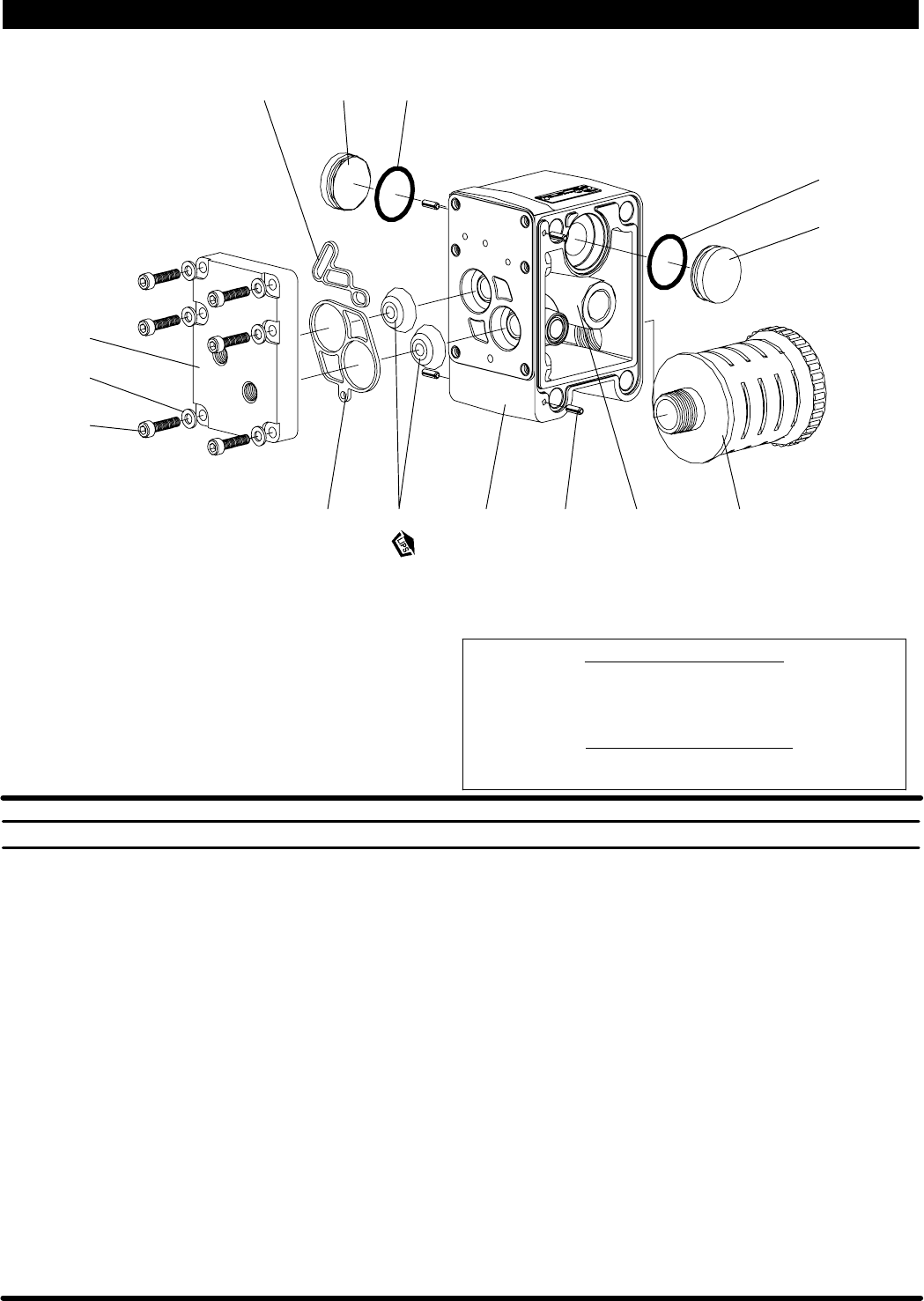

PARTS LIST / PE10P-X-X-A0S AIR SECTION

. TORQUE REQUIREMENTS ,

NOTE: DO NOT OVERTIGHTEN FASTENERS.

ALL FASTENERS ARE METRIC.

Torque (134) screw to 35 - 40 in. lbs (4.0 - 4.5 Nm).

LUBRICATION / SEALANTS

k Apply Lubriplate FML -2 grease to “O” rings, “U” Cups & mating parts.

U Apply anti-seize compound to threads at assembly.

U

. 134

133

121

173 k

121

132 k 176 k

Figure 3

101

181 103 201

173 k

160

166 k

TROUBLE SHOOTING

Product discharged from exhaust outlet.

S Check for diaphragm rupture.

S Check tightness of (6) diaphragm washer.

Air bubbles in product discharge.

S Check connections of suction plumbing.

S Check “O” rings between intake manifold and inlet side fluid caps.

S Check tightness of (6) diaphragm washer.

Motor blows air or stalls.

S Check (176) check valve for damage or wear.

S Check for restrictions in valve / exhaust.

Low output volume, erratic flow, or no flow.

S Check air supply.

S Check for plugged outlet hose.

S Check for kinked (restrictive) outlet material hose.

S Check for kinked (restrictive) or collapsed inlet material hose.

S Check for pump cavitation -- suction pipe should be sized at least as

large as the inlet thread diameter of the pump for proper flow if high

viscosity fluids are being pumped. Suction hose must be a non-col-

lapsing type, capable of pulling a high vacuum.

S Check all joints on the inlet manifolds and suction connections.

These must be air tight.

S Inspect thepumpfor solid objectslodgedin the diaphragmchamber

or the seat area.