PD07P-X-X (en) Page 5 of 8

)

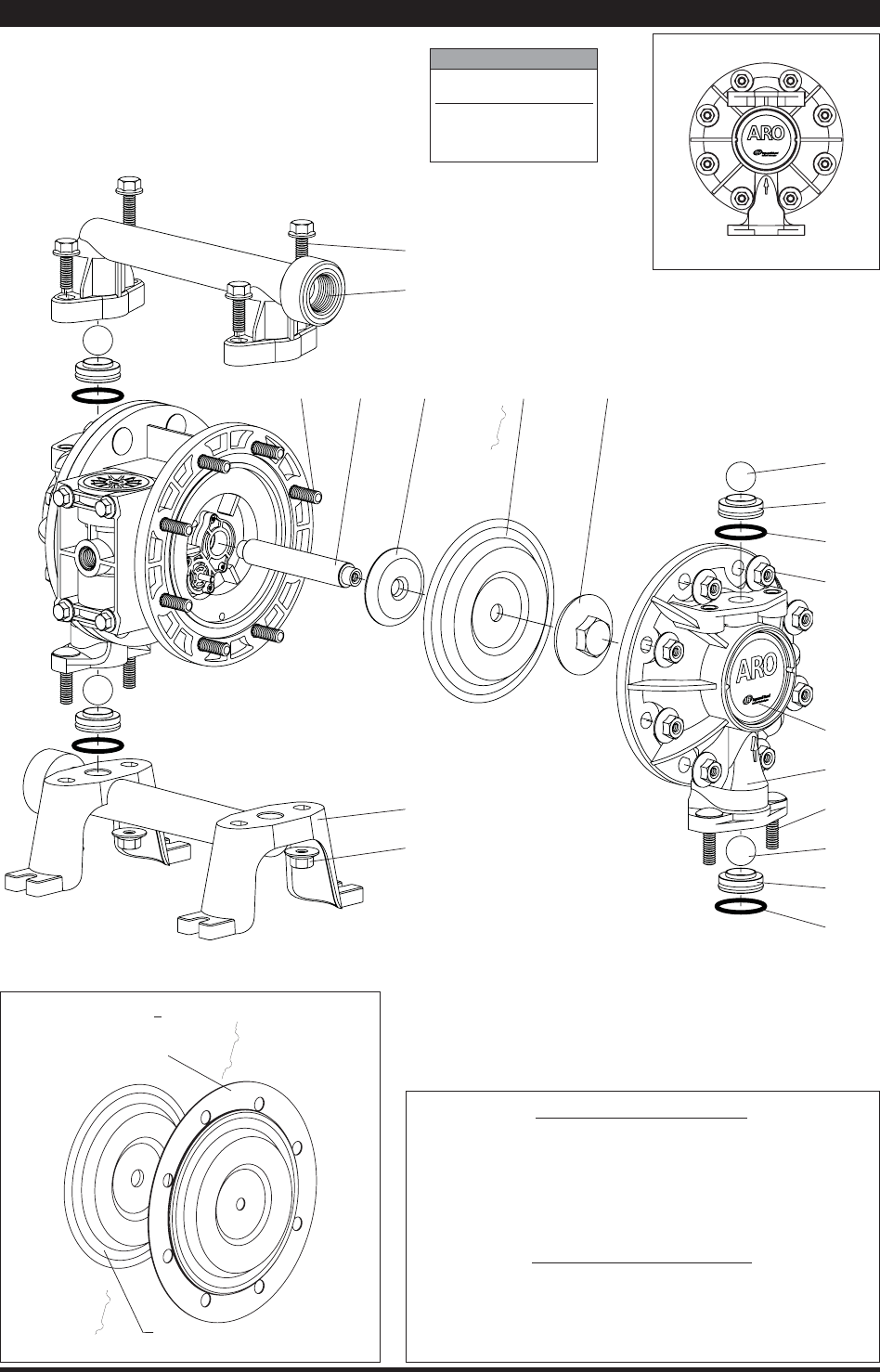

TORQUE REQUIREMENTS

(

NOTE: DO NOT OVERTIGHTEN FASTENERS.

(6) Diaphragm nut, 95 - 105 in. lbs (10.7 - 11.9 Nm).

(26) Bolt, 50 - 60 in. lbs (5.6 - 6.8 Nm), / alternately and evenly, then re-

torque after initial run-in.

(29) Nut, 50 - 60 in. lbs (5.6 - 6.8 Nm), / alternately and evenly, then re-

torque after initial run-in.

LUBRICATION / SEALANTS

Apply Lubriplate FML-2 grease (94276) to all “O” rings, “U” cups and

mating parts.

Apply pipe sealant to threads.

Apply anti-seize compound to threads and bolt and nut ange heads

which contact pump case when using stainless steel fasteners.

PARTS LIST / PD07P-X-X FLUID SECTION

View for PD07P-XPS-PXT (PTFE diaphragm) con guration

only.

FOR THE AIR MO-

TOR SECTION, SEE

PAGES 6 & 7.

Torque Sequence

3

2

7

5

1

8

6

4

COLOR CODE

Diaphragm Ball

Material Color Color

Hytrel Cream Cream

Santoprene Tan Tan

PTFE White White

27

8

Air side Santoprene (tan)

19

19

21

21

22

22

15

61

26

(

29

(

60

6

(

751

27

Figure 3

Fluid side PTFE (white)

7

29

(

77