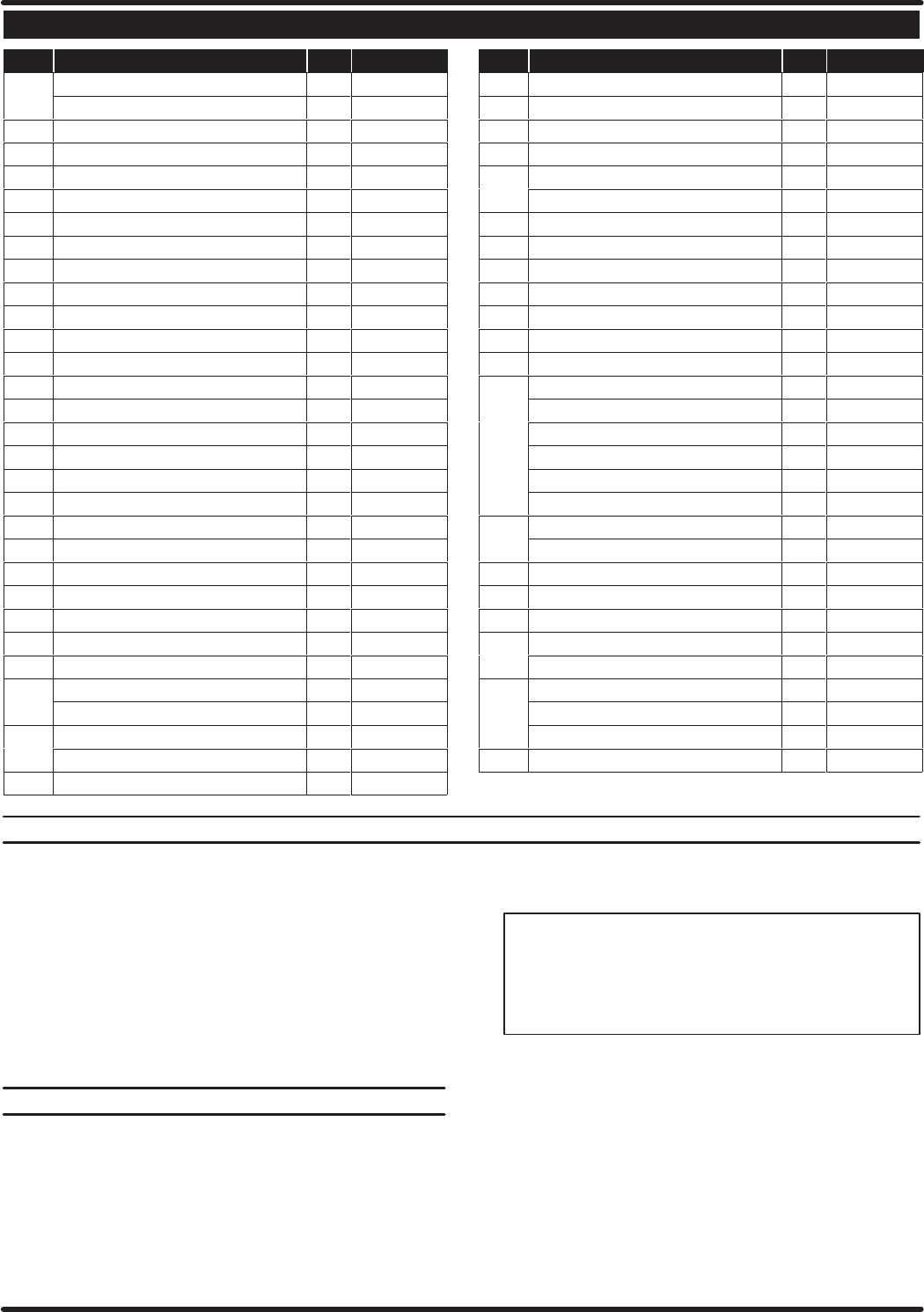

LM2203A-XPAGE2OF4

PARTS LIST / LM2203A–XX

Item Description (Size in inches)

(Qty)

Part No. Item Description (Size in inches)

(Qty)

Part No.

1 Bolt - LM2203A-( )1 (4) 94333

- LM2203A-( )2 (4) 96727466

2 Upper Cap (1) 94307

n3 Track Gasket (2) 94311

4 Sleeve (2) 94316

n5 ``O" Ring (1/16" x11/16" o.d.) (4) Y325-15

n6 ``O" Ring (1/8" x 3/4" o.d.) (4) Y325-206

7 Spool (2) 94310

n8 ``U" Cup (1/8" x 3/4"o.d.) (2) Y240-7

n9 ``O" Ring (.106" x .587" o.d.) (2) 15066

10 Muffler Housing (1) 94443

11 Cylinder (1) 94249

12 Retaining Ring (1) 94406

n13 ``U" Cup (3/16" x 2" o.d.) (2) Y240-23

14 Piston (1) 94312

15 Lower Cap (1) 94308

n16 ``O" Ring (1/8" x 1-3/8"o.d.) (1) Y325-216

17 Bushing (1) 94332

n18 Packing (1/4" x 1-5/8" o.d.) (1) 94337

n19 ``O" Ring (1/16" x 1" o.d.) (1) Y325-20

20 Piston Rod (1) 94313

21 Groove Pin (3/16" o.d. x 1-1/8" long) (1) 94338

22 Wavy Washer (1) 94336

23 Ball (3/4" dia.) (1) Y16-224

24 Inner Check (1) 94279

n25 ``O" Ring (3/16" x 1-7/16"o.d.) (1) Y325-319

26 Base - LM2203A-()1 (1) 94309

- LM2203A-( )2 (1) 94309-1

27 Nut - LM2203A-()1 (4) 93828

- LM2203A-( )2 (4) 96727474

n28 ``O" Ring (1/16" x 1-3/4"o.d.) (1) Y325-30

29 Tube (1) 94314-1

n30 ``O" Ring (3/32" x 1-5/16"o.d.) (1) Y325-122 k

31 Ball (1" dia.) (1) Y16-232

32 Ball Stop Pin (.187" dia. x 1.430" long) (1) 94339

33 Foot Valve - LM2203A-()1 (1) 94315

- LM2203A-( )2 (1) 94315-1

n34 ``O" Ring (1/16" x 7/16" o.d.) (1) Y325-11

n35 ``O" Ring (1/16" x 3/4" o.d.) (1) Y325-16

36 Adapter (1) 94447

37 Foam Liner (2) 94402

38 Ground Screw (#10 -32 x1/4") (1) 93005

39 Bung Assembly (includes items 40) (1) 67145-3

40 Thumb Screw (1/4" - 20 x 1") (3) Y66-59-C

41 Pipe Extension - LM2203A-31 (1) 94523-3

3/4"- 14NPT x30-1/8" -LM2203A-41 (1) 94523-4

3/4"- 14NPT x37-3/4" -LM2203A-51 (1) 94523-5

Rp3/4(3/4"-14BSPtaperx20-3/8") -LM2203A-32 (1) 94537-3

Rp3/4(3/4"-14BSPtaperx30-1/8") -LM2203A-42 (1) 94537-4

Rp3/4(3/4"-14BSPtaperx37-3/4") -LM2203A-52 (1) 94537-5

42 Valve Housing - LM2203A-( )1 (1) 94535

- LM2203A-( )2 (1) 94535-1

43 Ball Guide (1) 77904

44 Ball (1" dia.) (1) Y16-232

n45 ``O" Ring (3/32" x 1-7/16"o.d.) (1) Y325-124

46 Ball Seat - LM2203A-( )1 (1) 94534

- LM2203A-( )2 (1) 94534-1

47 Valve Ass'y (includes items 42 thru46)

- LM2203A-31, -41,-51 (1) 67085

- LM2203A-32, -42,-52 (1) 67085-1

n Parts in Repair Kit 637224

GENERAL

DESCRIPTION

Model LM2203A-X SeriesTwo-ball doubleacting pumps areintended

tobe usedprimarilyfor oiltransferand deliverysystems.It isbesttouse

this pump with low - medium viscosity fluids. It uses carbon steel and

other materials which make it compatible with most petroleum based

lubrication products. The two-balldesign providesbetter primingof the

lower foot valve. Double acting pumps will deliver material on both the

up and down stroke.

NOTE: If this pump was purchased separately (not part of a system),

consult your sales representative for compatible dispensing accessoĆ

ries which willbest match theapplication. All accessories mustbe able

to withstand the maximum pressure developed by the pump.

OPERATING

AND SAFETY PRECAUTIONS

READ THE GENERAL INFORMATION MANUAL INCLUDED FOR

ADDITIONAL OPERATING AND SAFETY PRECAUTIONS AND

OTHER IMPORTANT INFORMATION.

STATIC SPARK. Can cause explosion resulting in severe injury or

death. Ground the pump and pumping system.

EXCESSIVE INLET PRESSURE. Can cause explosion resultingin

severe injury or death. Do not exceed maximum operating

pressure of 375psi (25.9 bar) at 125 psi(8.6 bar) inlet air presĆ

sure. Do not run pump without using a regulator to limit air

supply pressure to the pump.

PUMPRATIO X

INLETPRESSURETOPUMP MOTOR

=

MAXIMUMPUMP

FLUIDPRESSURE

Pumpratioisanexpressionoftherelationshipbetweenthepumpmotorareaand

the lowerpump end area.EXAMPLE: When125 p.s.i. (8.6bar) inlet pressureis

supplied tothe motor ofa 3:1ratio pump itwill developa maximum of375 p.s.i.

(25.9 bar)fluid pressure(at noflow) -as thefluid controlis opened,the flowrate

will increase asthe motor cycle rateincreases to keep upwith the demand.

EXCESSIVE MATERIAL PRESSURE. Cancause equipmentfailure

resulting in severe injury or property damage. Do not exceed

the maximum material pressure of any component in thesysĆ

tem.

NOTICE: Thermal expansioncan occurwhen the fluidin the mateĆ

rial lines is exposed to elevated temperatures. Example: Material

lines locatedina non-insulatedroof areacanwarm dueto sunlight.

Install a pressure relief valve in the pumping system.

k Repair KitNote: ``O'' ringY325-28 (1/16''x 1-1/2''o.d.) includedforpump

Serial Nos.D9XX7XX thruL9117XX.Part Y325-122isused afterL912700.

Replacement warning label is available upon request, PN\ 94520.