66615X-X-C (en)Page 6 of 8

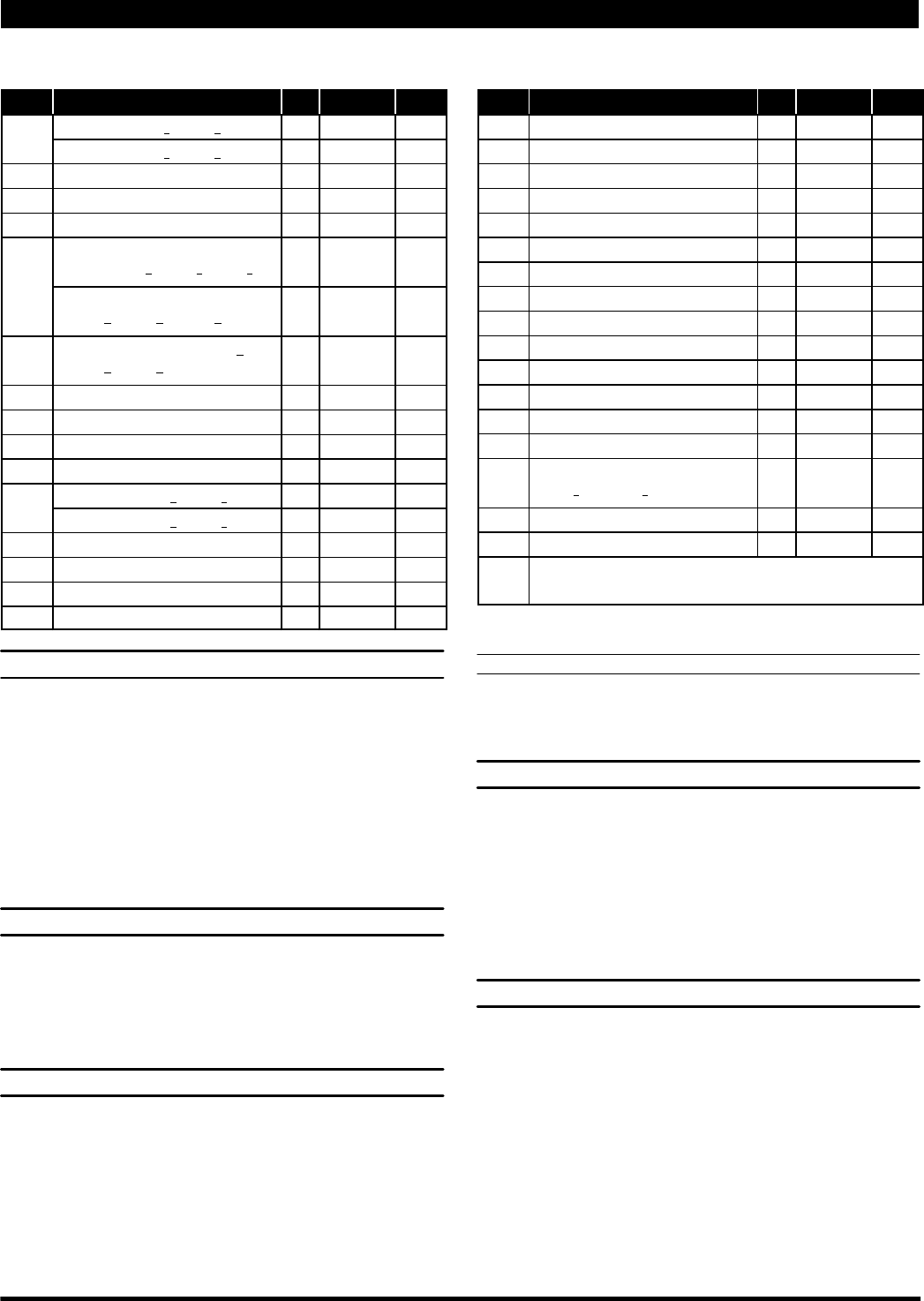

PARTS LIST / 66615X-X-C AIR SECTION

n Indicates parts included in 637118-C Air Section Service Kit.

SERVICE KIT NOTE: Service Kit 637118-C is a general repair kit for all 1” and larger ARO diaphragm pump air motors. It contains extra “O” rings and

extra parts that may not be needed to service this model.

Item Description (size) Qty Part No. [Mtl] Item Description (size) Qty Part No. [Mtl]

101 Motor Body (66615X- X, 66617X-X) (1) 94744 [A]

(66616X-X, 66618X-X) (1) 94742 [CI]

n 102 “O” Ring (1/16” x 1-1/4” o.d.) (2) Y325-24 [B]

V 103 Sleeve (1) 94528 [D]

n 104 Retaining Ring, TruArc (1-5/32” i.d.) (2) Y145-26 [C]

105 Screw / Lockwasher (1/4” - 20 x 5/8”)

(models 6661X0

-X, 6661X1-X, 6661X2-X)

(8) 93860 [C]

Cap Screw (1/4” - 20 x 5/8”) (models

6661XA

-X, 6661XB-X, 6661X5C-X)

(8) Y6-42-T [SS]

106 Lockwasher (1/4”) (models 6661XA-X,

6661XB

-X, 6661XC-X only)

(8) Y14-416-T [SS]

107 Plate (2) 93707-1 [SS]

n 108 Gasket (with notch) (1) 92878 [B/Ny]

V 109 Piston (1) 92011 [D]

n 110 “U” Cup (3/16” x 1-3/8” o.d.) (1) Y186-51 [B]

V 111 Spool (models 66615X-X, 66617X-X) (1) 92005 [A]

(models 66616X-X, 66618X-X) (1) 93047 [C]

V 112 Washer (1.557” o.d.) (5) 92877 [Z]

n 113 “O” Ring (small) (1/8” x 1-1/4” o.d.) (5) Y325-214 [B]

n 114 “O” Ring (large) (3/32” x 1-9/16” o.d.) (6) Y325-126 [B]

V 115 Spacer (4) 92876 [Z]

V 116 Spacer (1) 92006 [Z]

n 117 Gasket (1) 92004 [B/Ny]

118 Pilot Rod (1) 93309-2 [C]

n 119 “O” Ring (1/8” x 3/4” o.d.) (4) 93075 [U]

120 Spacer (3) 115959 [Z]

121 Sleeve Bushing (2) 98723-2 [Bz]

n 122 “O” Ring (3/32” x 9/16” o.d.) (2) 94820 [U]

n 123 Screw (#8 - 32 x 3/8”) (4) Y154-41 [C]

126 Pipe Plug (1/2 - 14 P.T.F. x 17/32”) (1) Y227-5-L [C]

127 90_ Street Elbow (3/4 - 1 4 N.P.T.) (1) Y43-5-C [C]

128 Pipe Plug (1/8 - 27 P.T.F. x 1/4”) (1) Y227-2-L [C]

197 Button Head Screw (1/4” - 20 x 1/4”) (2) 94987 [SS]

198 Button Head Screw (1/4” - 20 x 3/8”) (1) 94987-1 [SS]

201 Muffler (1) 350-568

231 Pipe Plug (1/4 - 18 N.P.T. x 0.41”) (models

66616

X-X and 66618X-X only)

(2) Y17-51-S [SS]

n Key-Lube “O” Ring Lubricant (1) 93706-1

10 Pak of Key-Lube (10) 637175

n Service Kitsinclude: Y212-101 (2)Screws (#10 -32 x 1/4”) used on unitsmf’d be-

tween 8/90 and 4/92 to retain the pilot bushing.

AIR MOTOR SECTION SERVICE

Service is divided into two parts - 1. Pilot Valve, 2. Major Valve.

GENERAL REASSEMBLY NOTES:

S Air Motor Section Service is continued from Fluid Section repair.

S Inspect and replace old parts with new parts as necessary. Look for

deep scratches on metallic surfaces, and nicks or cuts in “O” rings.

S Take precautions to prevent cutting “O” rings upon installation.

S Lubricate “O” rings with Key-Lube.

S Do not over-tighten fasteners, refer to torque specification block on

view.

S Re-torque fasteners following restart.

PILOT VALVE DISASSEMBLY

1. Remove (104) retaining ring.

2. Remove (123) screws and (122) “O” rings.

3. Remove (118) piston rod, (121) sleeve bushing, (119) “O” rings and

(120) spacers from the (101) motor body.

4. Remove (103) sleeve and (102) “O” rings.

PILOT VALVE REASSEMBLY

1. Replace two (102) “O” rings if worn or damaged and reinstall (103)

sleeve.

2. Install one of the (121) sleeve bushings, (119) “O” rings, (120)

spacers and the remaining (121) bushing.

3. Carefully push (118) pilot rod into bushings etc. and retain on each

end with the two (122) “O” rings, retain with (123) screws.

4. Replace (104) retaining rings.

MATERIAL CODE

[A] = Aluminum [CI] = Cast Iron [SS] = Stainless Steel

[B] = Nitrile [D] = Acetal [U] = Polyurethane

[Bz] = Bronze [Ny] = Nylon [Z] = Zinc

[C] = Carbon Steel

MAJOR VALVE DISASSEMBLY

1. Remove (107) plate (or leg depending on model), (108 and 117)

gaskets.

2. On thesideopposite the airinlet,push on the innerdiameter of (111)

spool. Thiswill forcethe (109)piston out.Continue pushingthe (111)

spool and remove. Check for scratches and gouges.

3. Reach into the air section (exhaust side) and remove (116) spacer,

(115) spacers, (113) “O” rings, (114) “O” rings, (112) washers, etc.

Check for damaged “O” rings.

MAJOR VALVE REASSEMBLY

1. Replace (112) washer, (114) “O” ring and (113) “O” ring onto (115)

spacer and insert etc.

NOTE: Be careful to orient spacer legs away from blocking in-

ternal ports.

2. Lubricate and carefully insert (111) spool.

3. Install (117) gasket and (107).

4. Lubricate and install (110) packing cup and insert (109) piston into

(air inletside) cavity, the(110) packingcup lipsshould pointoutward.

5. Install (108) gasket and replace (107).

V “Smart Parts”, keep these items on hand in addition to the service kits for fast repair and reduction of down time.