classic HE - Installation & Servicing

39

SERVICING

1. Refer to Frame 61.

2. Remove the two fan electrical connections, the red

pressure sensing pipe, the blue CO/CO

2 sensing

pipe and the two fan fixing screws.

3. Pull the fan forward, remove and retain.

4. Fit the new fan and reassemble in reverse order,

ensuring the fan leads, 2 sensing tubes and the two

fan fixing screws are reconnected.

5. Check the operation of the boiler.

71

FAN REPLACEMENT

5. Disengage the PCB from the mounting posts and withdraw

from the control box.

6. Fit the new PCB and reassemble in reverse order.

7. Check the operation of the boiler.

Fuse.

To change the fuse, prise it out of the holder and disengage

the fuse. Refer to Frame 78 for fuse location.

73

PRINTED CIRCUIT BOARD (PCB) REPLACEMENT

1. Refer to Frame 61.

2. Remove the control box fixing screws and swing the

control box down into the servicing position.

3. Disconnect the detection lead from the PCB.

4. Unplug all the Molex connectors from the PCB.

74

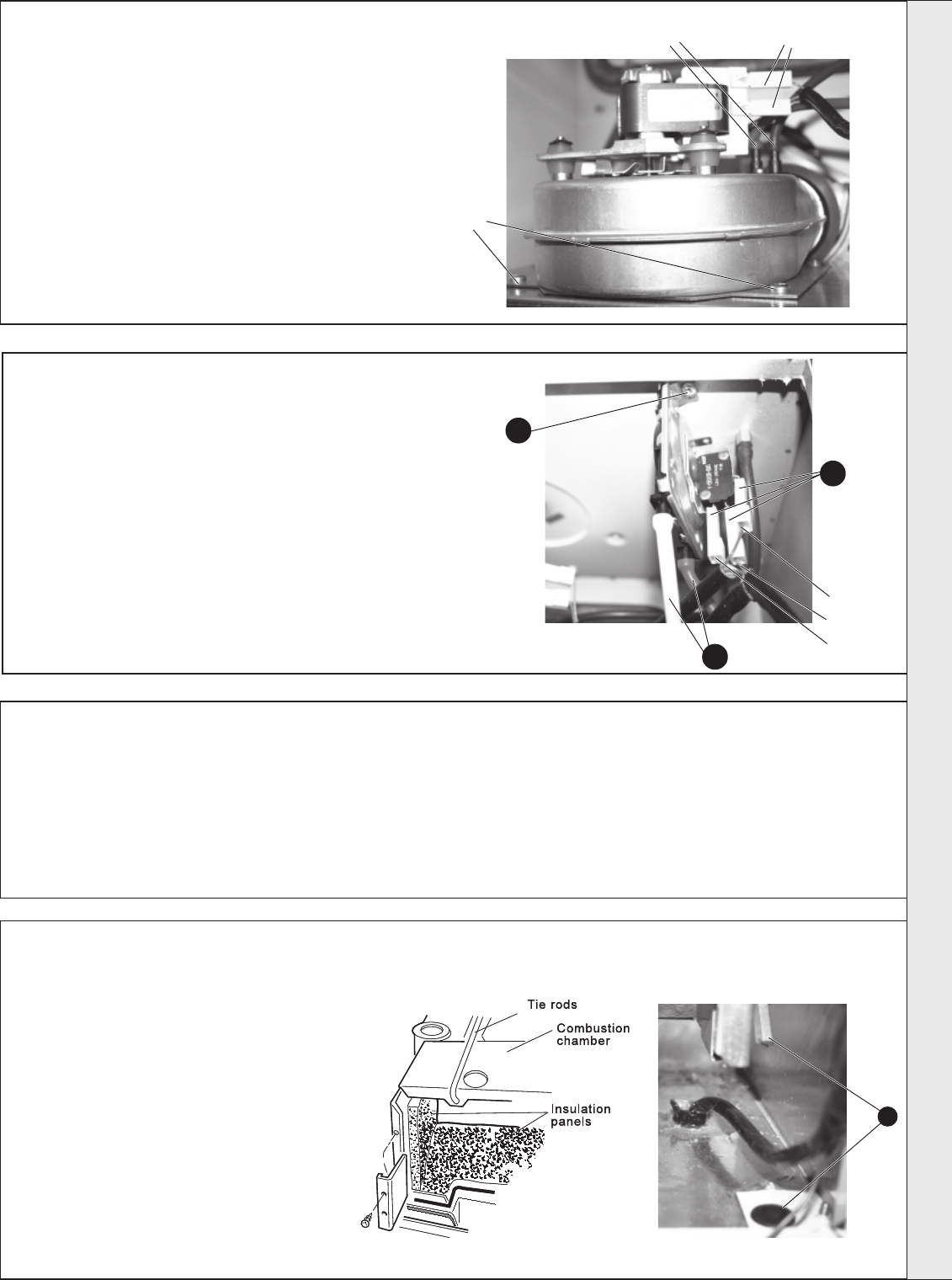

COMBUSTION CHAMBER INSULATION REPLACEMENT

1. Refer to Frame 61.

2. Remove the burner and air box assembly. Refer to

Frame 54.

3. Remove the 4 tie rods.

Note. remove rubber grommets to gain access to

side tie rod screwdriver slots.

4. Remove the combustion chamber.

5. Remove the 2 side panel retaining brackets.

6. Remove the side insulation panels.

7. Remove the front and rear insulation panels.

8. Fit the new front and rear insulation panels.

9. Fit the new side panels and retain with the

brackets and screws previously removed.

10.Reassemble in reverse order.

72

AIR PRESSURE SWITCH (APS) REPLACEMENT

1. Refer to Frame 61.

2. Remove the APS fixing screw.

3. Remove the 2 sensing tubes from the APS.

4. Remove the 3 electrical connections from the APS.

5. Fit the new APS and reassemble in reverse order.

6. Check the operation of the boiler.

red

3

2

white

red

violet

yellow

4

Fixing

screws

Air pressure switch &

CO/CO

2 sensing pipes

Electrical

connections

3

SERVICING

201850-6.pmd 21/02/2008, 12:5839