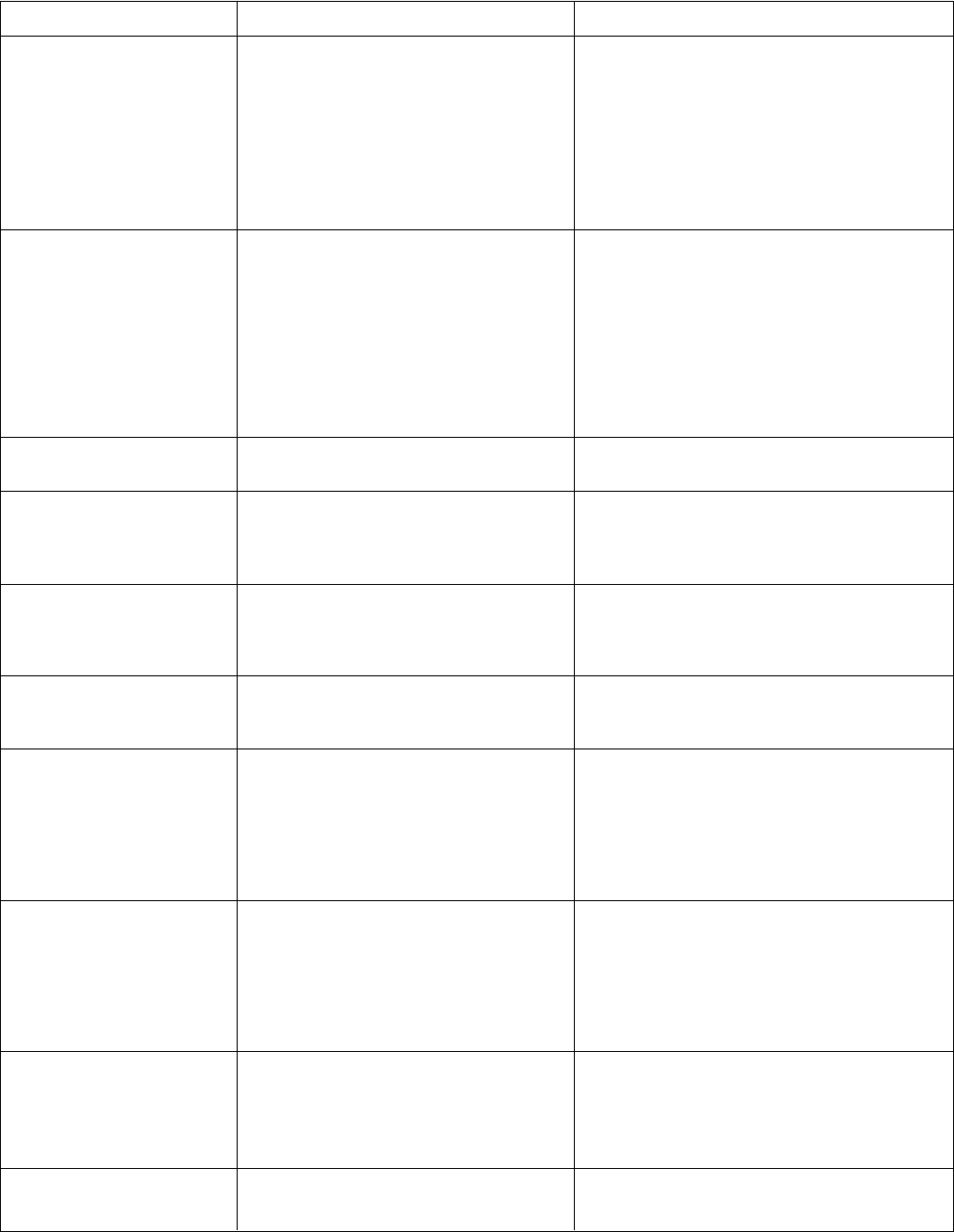

7

Trouble Shooting Guide

Before calling for service, follow the steps below, then MANUALLY REGENERATE your softener.

PROBLEM CAUSE CORRECTION

1. Softener delivers hard water A. Bypass valve is open

B. No salt in brine tank

C. Insufficient water flowing into brine tank

D. Salt bridged

E. Loose brine line

F. Plugged injector assembly

A. Close bypass valve.

B. Add salt to brine tank and maintain salt level

above water level.

C. Check salt setting and clean brine line flow

control if plugged.

D. Break salt bridging – see page 6.

E. Tighten connections at control valve and at

brine valve.

F. Clean/replace injectors and screen.

2. Intermittent soft water A. Control will not draw brine properly

B. Using hot water during regeneration

cycle

C. Incorrect salt setting

D. Softener capacity too small

A. Maintain water pressure at 20 psi minimum.

Check for restrictions in drain line. Clean or

replace injector assembly. Check for air leaks

between control valve and air check valve

and tighten connections.

B. Avoid using hot water at this time as water

heater will fill with hard water.

C. Adjust salt setting.

D. Increase capacity by replacing with larger

unit.

3. Softener regenerates at

wrong time

A. Power failure or incorrect setting A. Restore power and reset time of day.

4. Unit uses too much salt A. Improper salt setting

B. Excessive water in brine tank

A. Check salt usage and salt setting.

B. Remove water. Clean drain line flow control,

brine line flow control, injector system and

brine valve.

5. Loss of water pressure A. Inlet to control blocked with iron

buildup or foreign matter

B. Iron buildup in water conditioner

A. Clean line to water softener. Remove piston

and clean control.

B. Clean control and add resin cleaner to resin

bed.

6. Iron in conditioned water A. Fouled resin bed A. Check backwash, brine draw and brine tank

fill. Clean control and add resin cleaner to

resin bed.

7. Softener fails to draw brine A. Drain line flow control is plugged

B. Brine line flow control is plugged

C. Injector assembly is plugged

D. Line pressure is too low

E. Internal control leak

A. Clean drain line flow control.

B. Clean drain line flow control.

C. Clean/replace injectors and screen.

D. Increase line pressure. Line pressure must

be at least 20 psi (139.9 KPa) at all times.

E. Change seals and spacers and/or piston

assembly.

8. Drain flows continuously A. Foreign material in control

B. Internal control leak

C. Control valve is jammed in brine or

backwash position

D. Drive motor stopped or jammed

A. Remove piston assembly and inspect bore,

remove foreign material and check control in

various regeneration positions.

B. Replace seals and/or piston assembly.

C. Replace piston and seals and spacers.

D. Replace drive motor.

9. Softener fails to regenerate A. No salt in brine tank

B. Injector assembly plugged

C. Salt bridged

D. Insufficient salt used per regeneration

E. Softener capacity too small

A. Add salt.

B. Clean/replace injectors and screen.

C. Break salt bridging – see page 5.

D. Check and adjust salt setting.

E. Replace softener with larger unit.

10. Softener regenerates every

night

A. Softener capacity too small A. Replace with larger unit.