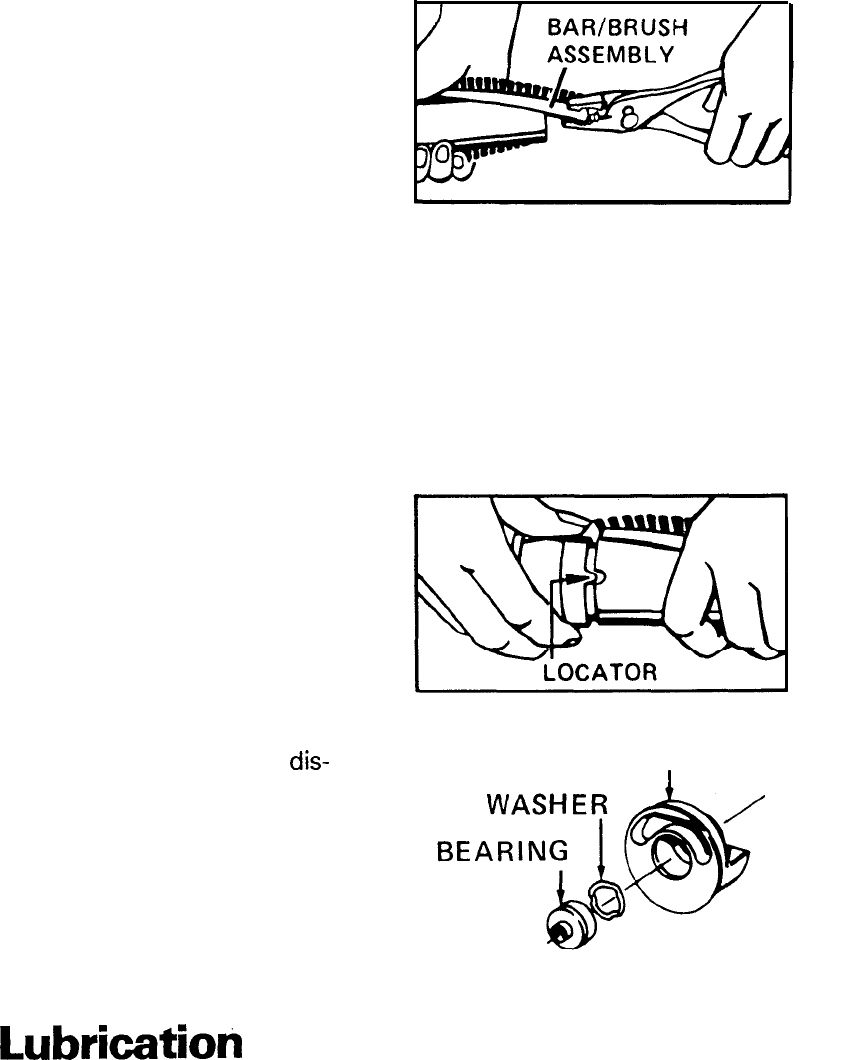

3. Note position of bar-brush as-

.

semblies to insure correct replace-

1

/

ment.

/

Remove bar-brush assemblies by

pulling them from agitator slots.

Use pliers if necessary.

The word “BAR” is stamped near

the slots on the agitator.

Match the bar side of the bar

brush assembly with the label on

the agitator shell. Slide the new

assemblies into the slots, while

twisting the assemblies in a coun-

terclockwise motion. Push in as

far as possible, tapping the other

end lightly if necessary. Be sure

brushes and bars are aligned for

full length of agitator.

4. Reassemble agitator parts. Line

up locator on end sections with

slot on agitator. Push end sections

into position.

Screw on end plates and tighten.

5. Should you accidentally dis-

place the bearing during disas-

sembly, reassemble as shown.

END SECTION

Replace belt, agitator and nozzle

cover.

Lubricatiori

The motor is equipped with one ball bearing and one sleeve bearing. These

bearings contain sufficient lubrication for the life of the motor. The addition

of lubricant could cause damage.

Therefore, do not add lubricant to

either motor bearing.

The agitator is equipped with two ball bearings that should be lubricated

periodically. This should be done by a Hoover Factory Service Center or an

Authorized Hoover Warranty Service Dealer.

17