VR8104, VR8204 AND VR8304 INTERMITTENT PILOT COMBINATION GAS CONTROLS

69-1225—48

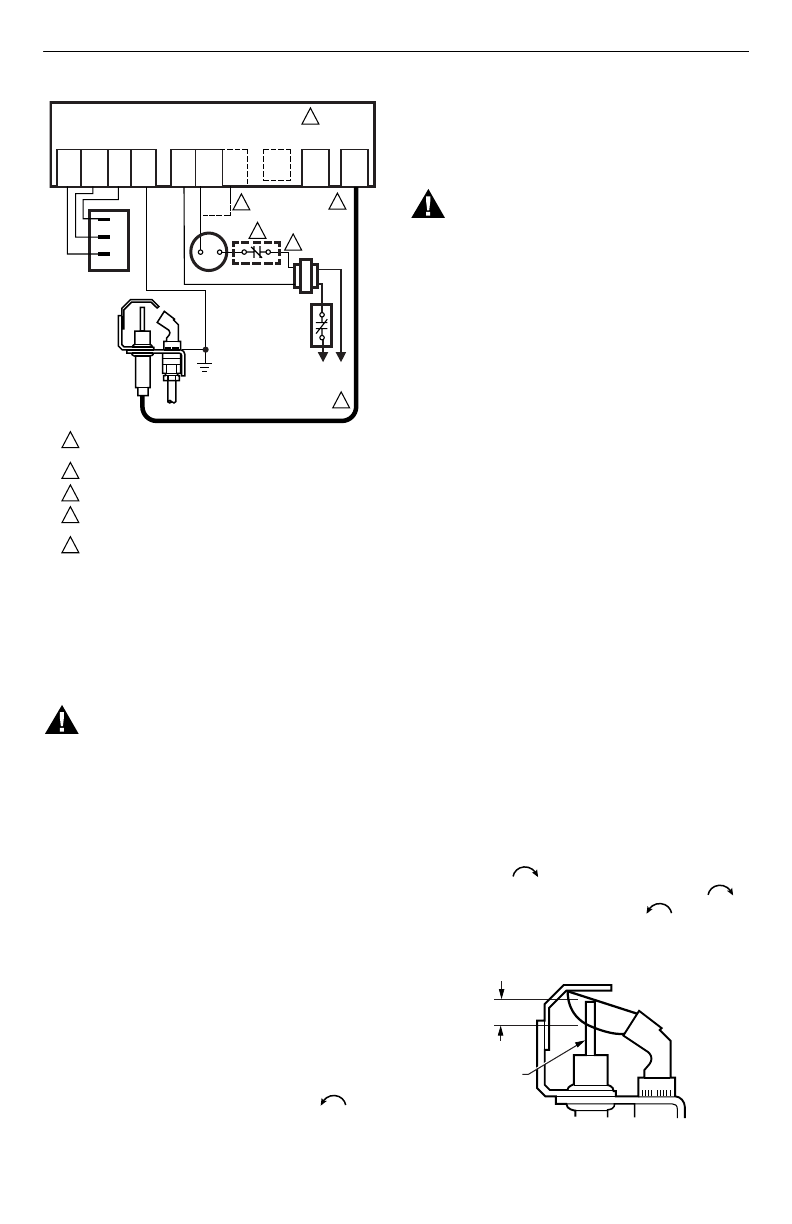

Fig. 8. Typical wiring connections for 24 volt control

in intermittent ignition system with S8600.

STARTUP AND CHECKOUT

WARNING

Fire or Explosion Hazard.

Can cause property damage, severe injury

or death.

1. Do not force the gas control knob on the

appliance. Use only your hand to turn the gas

control knob. Never use any tools.

2. If the knob does not operate by hand, the

control should be replaced by a qualified

service technician.

Gas Control Knob Settings

Gas control knob settings are as follows:

OFF: Prevents pilot and main gas flow through the

control.

ON: Permits gas to flow into the control body. Under

control of the thermostat and intermittent pilot module,

gas can flow to the pilot and main burners.

NOTE: Controls are shipped with the gas control knob

in the ON position.

Turn On System

Rotate the gas control knob counterclockwise to

ON.

Turn On Main Burner

Follow appliance manufacturer instructions or turn up

thermostat to call for heat.

Perform Gas Leak Test

WARNING

Fire or Explosion Hazard.

Can cause property damage, severe injury

or death.

Perform Gas Leak Test every time work is done

on a gas system.

IMPORTANT

Do not spray soap and water solution on the

gas control. Do not use an excessive amount of

soap and water solution to perform the gas leak

test. These can damage the control.

Gas Leak Test

1.

Paint pipe connections upstream of the gas control

with rich soap and water solution. Bubbles indicate

a gas leak.

2.

If a leak is detected, tighten the pipe connections.

3.

Light the main burner. Stand clear of the main

burner while lighting to prevent injury caused from

hidden leaks that could cause flashback in the

appliance vestibule.

4.

With the main burner in operation, paint the pipe

joints (including adapters) and the control inlet and

outlet with rich soap and water solution.

5.

If another leak is detected, tighten the adapter

screws, joints, and pipe connections.

6.

Replace the part if a leak cannot be stopped.

Check and Adjust Pilot Flame

The pilot flame should envelop 3/8 to 1/2 in. (10 to 13

mm) of the tip of the igniter-sensor. See Fig. 9. If the pilot

flame is small or lazy, the inlet gas pressure may be too

low, or the pilot orifice may be partially clogged. Check

and repair as necessary. If the pilot flame is hard and

noisy, the inlet gas pressure may be too high. The gas

control has a pilot adjustment mechanism to reduce the

pilot flow if necessary. If pilot adjustment is necessary,

proceed as follows:

1.

Remove pilot adjustment cover screw. See Fig. 6.

2.

The pilot adjustment is shipped at the full pilot gas

flow rate. Turn the inner adjustment screw

clockwise if the inlet pressure is too high.

Turn the inner adjustment screw clockwise

to decrease or counterclockwise to increase

pilot flame.

3.

Replace the cover screw after the adjustment to

prevent gas leakage.

Fig. 9. Proper flame adjustment.

MV MV/PV PV

GND

(BURNER)

24V

GND

24V

SPARK

S8600

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

ALTERNATE LIMIT CONTROLLER LOCATION.

MAXIMUM WIRE LENGTH 3 ft [.9 m].

CONTROLS IN 24V CIRCUIT MUST NOT BE IN

GROUND LEG TO TRANSFORMER.

FOR MODULE WITH TH-W TERMINAL AND VENT DAMPER

PLUG, CONNECT THERMOSTAT TO TH-W. LEAVE

24V OPEN. DO NOT REMOVE VENT DAMPER PLUG.

1

2

3

4

5

M9056

GROUND

PILOT GAS

SUPPLY

2

4

3

Q345, Q346,

Q348, Q362, Q381

PILOT BURNER/

IGNITER-SENSOR

L1

(HOT)

1

L2

LIMIT

CONTROLLER

THERMOSTAT

5

TH-W

(OPT)

VENT

DAMPER

PLUG

(OPT)

5

GAS CONTROL

TERMINALS

PV

PV/MV

MV

SENSE

PROPER FLAME

ADJUSTMENT

IGNITER-

SENSOR

M3080A

3/8 TO 1/2 INCH

(10 TO 13 mm)