V4943/V8943B,C,N; V4944/V8944B,C,L,N REGULATING DIAPHRAGM GAS VALVES

11 65-0214—08

Checkout

1. Valve outlet pressure measurements are made at a point

approximately five pipe diameters downstream from the

valve outlet. Consider pressure measurements made at

the outlet pressure tap as reference measurements only,

because turbulence and dynamic gas flow effects may

result in erratic pressure readings.

2. Shut off gas supply to valve and make sure valve is

closed when setting up pressure measuring equipment.

3. Set up pressure measuring equipment.

4. Make sure the valve is closed. Turn on the supply gas to

the valve.

5. Set the thermostat or controller to energize the valve and

check the final outlet pressure. See step 1. Allow enough

time for the system pressure to stabilize.

6. For regulator setpoint and spring range, please refer to

Table 3.

7. The low pressure regulator (V4944/V8944B,C,L,N) and

high pressure regulator V4943V8943B,C,N and

V4944/V8944B,C,L,N) adjustment screws (use a T-40

six-lobe [TORX®] driver or 5/16-in. standard driver) are

located under the slotted aluminum screw cap(s) of the

adjustment screw housings (see Fig. 1). To adjust the

pressure setting:

a. Temporarily remove the slotted aluminum screw cap

and gasket from the housing that contains the

regulator adjustment setscrew.

b. Turn the adjustment setscrew (use a T-40 six-lobe

[TORX®] driver or 5/16-in. standard driver) clockwise

to increase the pressure setting or counterclockwise

to decrease the pressure setting. Allow adequate time

(30 to 60 seconds) for the pressure to reach

equilibrium between pressure adjustments.

c. After the regulators have been properly adjusted,

replace the gasket and slotted aluminum screw cap

on the adjustment screw housing.

8. Start the system and observe its operation through at

least one complete cycle to make sure the valve

functions properly.

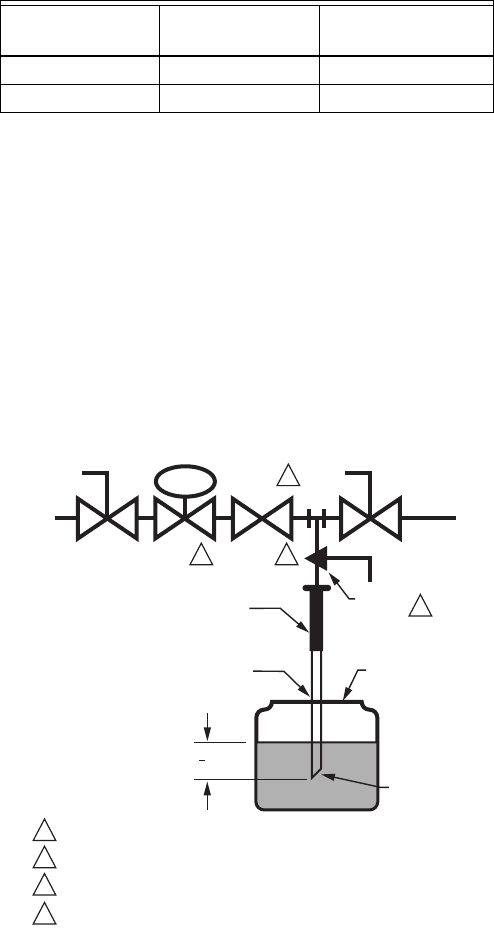

Valve Leak Test (See Fig. 15).

This test checks the tightness closure of a gas safety shutoff

valve. It should be performed by a qualified technician during

the initial startup of a burner system, or whenever the valve is

replaced (see Service Information section). It is recommended

that this test also be included in scheduled inspection and

maintenance procedures.

1. De-energize the control system to make sure there is no

power to the safety shutoff valve (C) shown in Fig. 15.

2. Close the upstream manual gas cock (A).

3. Make sure the manual test petcock (F) is closed in the

leak test tap assembly (D).

4. Remove the leak test tap plug (valve outlet pressure tap

can be used as a test tap) and connect the test

apparatus to the leak test tap (D).

5. Close the downstream manual gas cock (E).

6. Open the upstream manual gas cock (A).

7. Run the safety shutoff valve (C) to its fully open position

(through the safety system); then immediately

de-energize the system to close the valve.

8. Immerse a 1/4 in. tube vertically 1/2 in. (13 mm) into a jar

of water.

9. Slowly open the test petcock (F).

10. When the rate of bubbles coming through the water

stabilizes, count the number of bubbles appearing during

a ten-second period. Each bubble appearing during a

ten-second period represents a flow rate of

approximately 0.001 cfh.

To meet code requirements, leakage must not exceed the

values in Table 5.

Table 5. Allowable Leakage Rates.

a

Based on air standard conditions, test pressures in

accordance with ANSI Z21.21, Section 2.4.2 and a maximum

of 235 cc/h per inch of seal-off-diameter. Seal-off diameter is

not the same as pipe size.

11. Close the upstream manual gas cock (A).

12. Close the test petcock (F), remove the test apparatus,

and replace the leak test tap plug (D).

13. Open the upstream manual gas cock (A) and energize

the safety shutoff valve (C).

14. Test with soap bubbles to make sure there is no leak at

the test tap (D).

15. De-energize the safety shutoff valve (C).

16. Open the downstream manual gas cock (E).

17. Restore the system to normal operation.

Fig. 15. Valve leak test.

Pipe Size

(in.)

Allowable

a

Leakage

Number of Bubbles

per 10 sec.

1, 1-1/4 353 11 (Nat. gas), 7 (LP)

1-1/2, 2 453 14 (Nat. gas), 9 (LP)

M9547F

GAS

SUPPLY

UPSTREAM

MANUAL

GAS COCK

DOWNSTREAM

MANUAL

GAS COCK

BURNER

DABC E

F

PRV

MANUAL

TEST

PETCOCK

SSOV

1/4 IN. (6 MM)

FLEXIBLE

TUBING

1/4 IN. (6 MM)

ALUMINUM OR

COPPER PILOT

TUBING

JAR OR GLASS

WITH WATER

CUT AT

45 DEGREE

ANGLE

CAN ALSO BE A PERMANENT PETCOCK.

PRV = PRESSURE REGULATING VALVE.

SSOV = SAFETY SHUTOFF VALVE.

USE ONLY ONE OF THE DOWNSTREAM TAPS ON THE SS0V.

1

2

3

4

4

2 3

1

1

2

(13 MM)

LEAK

TEST

TAP