S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

69-2076—01 6

NOTE: Cable length must be 36 in. (0.9 m) or less. The

cable must not be in continuous contact with a

metal surface or spark voltage will be greatly

reduced. Use ceramic or plastic standoff

insulators as required.

1. Connect one end of the cable to the male

quick-connect SPARK terminal on the module.

2. Connect the other end of the cable to the igniter or

igniter-sensor stud on the pilot burner/igniter-

sensor.

Connect Vent Damper (Vent Damper Models)

A vent damper can be used with modules provided with a

vent damper plug connector. The Molex

®

plug provided

simplifies wiring connections.

To connect the vent damper, follow the wiring diagrams

supplied with the vent damper for typical connections.

Connect Remaining Module Connectors

Connect remaining system components to the ignition

module terminals as shown in the appropriate wiring

diagrams, Fig. 4 and 5.

Connect Igniter (HSI Models)

Prepare wiring harness:

1. Use wire suitable for the temperatures near the HSI

igniter.

2. Use wire suitable for the voltage ratings of the

specific igniter.

3. Attach connector per Table 4, HSI Specific

Connectors.

Connect Gas Control

Use No. 18 AWG solid or stranded wire. Connect to gas

control terminals as shown in wiring diagrams, using

terminals appropriate to the gas control.

Ground Control System

The igniter, flame sensor and module must share a

common ground with the main burner. Use AWM

insulated wire with a minimum rating of 105°C (221°F) for

the ground wire; asbestos insulation is not acceptable. If

necessary, use a shield to protect the wire from radiant

heat generated by the burner.

The burner serves as the common grounding area. If

there is not a good metal-to-metal contact between the

burner and ground, run a lead from the burner to ground.

NOTE: “Earth” ground is not required.

S937XA Hot Surface Ignition Versions

These models provide operating control of a direct ignition

system using a hot surface igniter. Additional components

required to complete the system must be ordered

separately. They include:

• Dual Valve Combination Gas Control: Any direct

ignition gas control with 2.0A maximum main valve

rating. VR8205, VR845, VR854, VR8450, or VR8540

recommended.

• Hot Surface Igniter: Norton Model 201 or 271 or

equivalent.

NOTE: If igniter other than Norton Model 201 or 271 is

used, the igniter must meet the following

minimum specifications, required over the life of

the igniter:

1. Igniter must reach 1000°C (1832°F) within 34

seconds with 102 Vac applied.

2. Igniter must maintain at least 500 megohms

insulation resistance between the igniter

leadwires and the igniter mounting bracket.

3. Igniter current draw at 132 Vac must not

exceed 5 A.

Sensor: Separate sensor required. Honeywell Q354

recommended.

Igniter Wiring: Provide wiring harness to suit application.

• Leadwires: No. 18 AWG, stranded copper with 105°C

rated, 1/16 in. AWM insulation.

• Terminals: Insulated. See Table 4 for HSI specific

connectors.

Transformer: Add current ratings of module, gas control,

vent damper and any other components of the control

system to determine transformer size requirements.

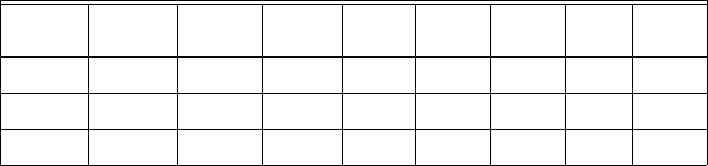

Table 2. Specific Ignition Timings.

a

Ignition Activation Period is the time that the hot surface igniter remains powered after the gas valve opens.

b

Purge Timing specified in seconds.

Model Ignition Type Draft Type

No. of

Ignition

Trials

Igniter/

Sensor

Type

Automatic

Restart

Time

Ignition

Activation

Period

a

Prepurge

Timing

b

Postpurge

Timing

b

S9360A Intermittent

Pilot - Spark

Induced 3 Separate 1 hour N/A 15 5

S9360A Intermittent

Pilot - Spark

Atmospheric 3 Separate 1 hour N/A 1 5

S9370A Direct Hot

Surface

Induced 3 Separate 1 hour 2.5 5 15