S9360A, S9361A, S9370A, S9371A INTEGRATED BOILER CONTROLLERS

69-2076—01 4

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

1. The module can malfunction if it gets wet,

leading to accumulation of explosive gas.

• Never install where water can flood, drip or

condense on module.

• Never try to use a module that has been

wet—replace it.

2. Liquefied petroleum (LP) gas is heavier than air

and will not vent upward naturally.

• Do not light pilot or operate electric switches,

lights, or appliances until you are sure the

appliance area is free of gas.

3. If a new gas control is to be installed, turn off

gas supply before starting installation. Conduct

Gas Leak Test according to gas control

manufacturer instructions after the gas control

is installed.

4. If module must be mounted near moisture or

water, provide suitable waterproof enclosure.

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning wiring

to prevent electrical shock or equipment damage.

Perform Preinstallation Safety Inspection

The preinstallation checks described in ANSI Standard

Z21.71 must be done before a replacement module is

installed. If a condition which could result in unsafe

operation is detected, the appliance should be shut off

and the owner advised of the unsafe condition. Any

potentially unsafe condition must be corrected before

proceeding with the installation.

Maintenance Requirements in Severe

Environments

Regular preventive maintenance is important in any

application, but especially so in commercial, agricultural,

and industrial applications, because:

1. In such applications, particularly commercial, the

equipment can operate 100,000 to 200,000 cycles

per year. Such heavy cycling can wear out the gas

control in one to two years. A normal boiler applica-

tion, for which the controls were intended, typically

operate fewer than 10,000 cycles per year.

2. Exposure to water, dirt, chemicals, and heat can

damage the module or the gas control and shut

down the control system. A NEMA 4 enclosure can

reduce exposure to environmental contaminants.

The maintenance program should include regular

checkout of the system as outlined under Checkout.

WARNING

Fire or Explosion Hazard.

Can cause severe injury, death or property

damage.

Do not attempt to take the module apart or to

clean it. Improper reassembly and cleaning may

cause unreliable operation, leading to an

accumulation of explosive gas.

Maintenance frequency must be determined individually

for each application. Some considerations are:

Cycling frequency. Appliances that may cycle more than

10,000 times annually should be checked monthly.

Intermittent use. Appliances that are used seasonally

should be checked before shutdown and again before the

next use.

Consequence of unexpected shutdown. Where the cost of

an unexpected shutdown would be high, the system

should be checked more often.

Dusty, wet, or corrosive environment. Since these

environments can cause the controls to deteriorate more

rapidly, the system should be checked more often.

Any control should be replaced if it does not perform

properly on checkout or troubleshooting. In addition,

replace any module if it is wet or looks like it ever has

been wet. Protective enclosures as outlined under

Planning the Installation are recommended regardless of

checkout frequency.

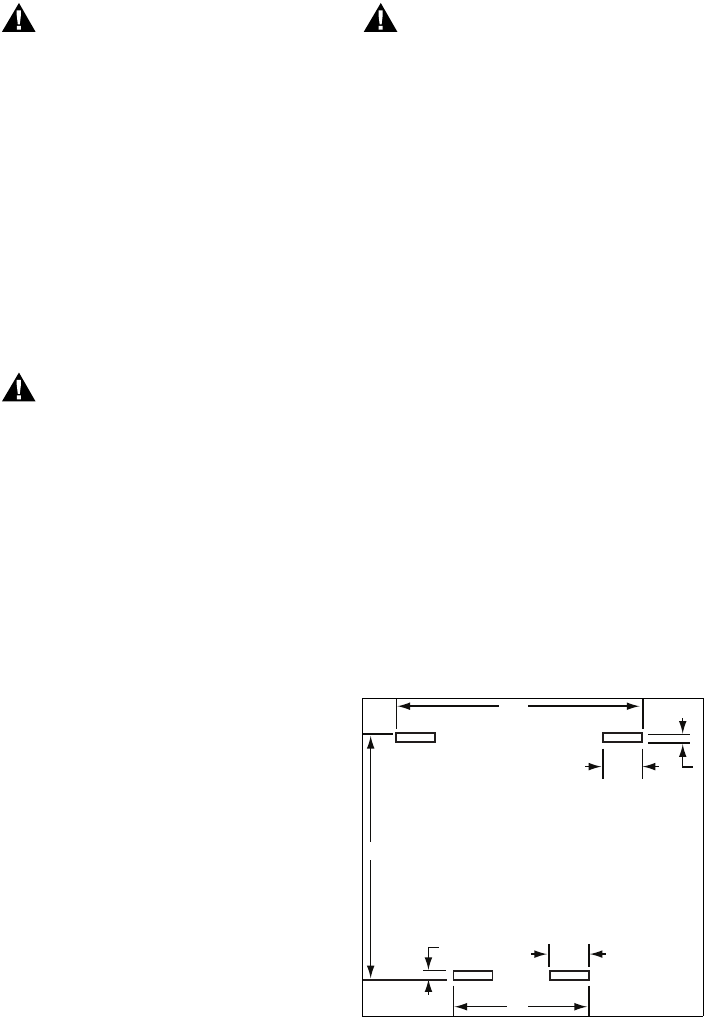

Mount Module

Select a location close enough to the burner to allow a

short (3 ft. [0.9 m] maximum), direct cable route to the

igniter. Ambient temperature at the module must be within

the range listed under Specifications. The module must

be protected from water, moisture, corrosive chemicals

and excessive dust and grease. Refer to Fig. 2 and 3 for

recommended slot/hole pattern in appliance.

Fig. 2. Recommended slot/hole pattern in appliance

(in mm).

100

M24198

16

16

55

4

99.5

4