LENGTH OF ELEMENT (in inches) [millimeters] :

Self-supporting model-10 [254] (total length of

element).

Capillary models-24 [609.6], 36 [914.4], and 54

[ 1371.61 (flexible capillary length). Add 6 [ 152.41

inches for total length including sensing element.

SENSING ELEMENT: Liquid-filled.

ADJUSTMENT MEANS: Indicators are inside cover.

MOUNTING MEANS: Two holes in backplate.

DIMENSIONS: See Fig. 1.

FINISH: Gray.

UNDERWRITERS LABORATORIES INC COMPO-

NENT RECOGNIZED: File No. MP466, Guide No.

MBPR-2.

CANADIAN STANDARDS ASSOCIATION CERTI-

FIED: File No. LR1620, Guide No. 400-E-0.

OPTIONAL SPECIFICATION: L4017A Combination

Fan and Limit Control with fan-off scale. Unit has

fixed fan and limit differentials. Fan-on setting is

fixed at 33 F [19 C] above fan-off setting. With case

and cover.

ACCESSORY: Adapter plate bag assembly, Part No.

21136E, to match mounting holes of competitive

devices.

1. Installer must be a trained, experienced

serviceman.

2. Disconnect electricity before connecting wiring

to prevent electrical shock or equipment

damage.

3. Conduct a thorough checkout after the instal-

lation is complete.

LOCATION

Locate the control on a solid area of the furnace

casing or jacket or on the discharge plenum. The stand-

off plate furnishes a heat barrier, and a l/4 inch

[6.4 mm] thick asbestos washer (Part No. 106638) is

provided to slip over the capillary for air seal between

the element clearance hole and the diaphragm power

head (see Fig. 4). Since the ambient temperature rating

is 190 F [88 C] at the switches, this heat barrier

should be adequate for all normal applications.

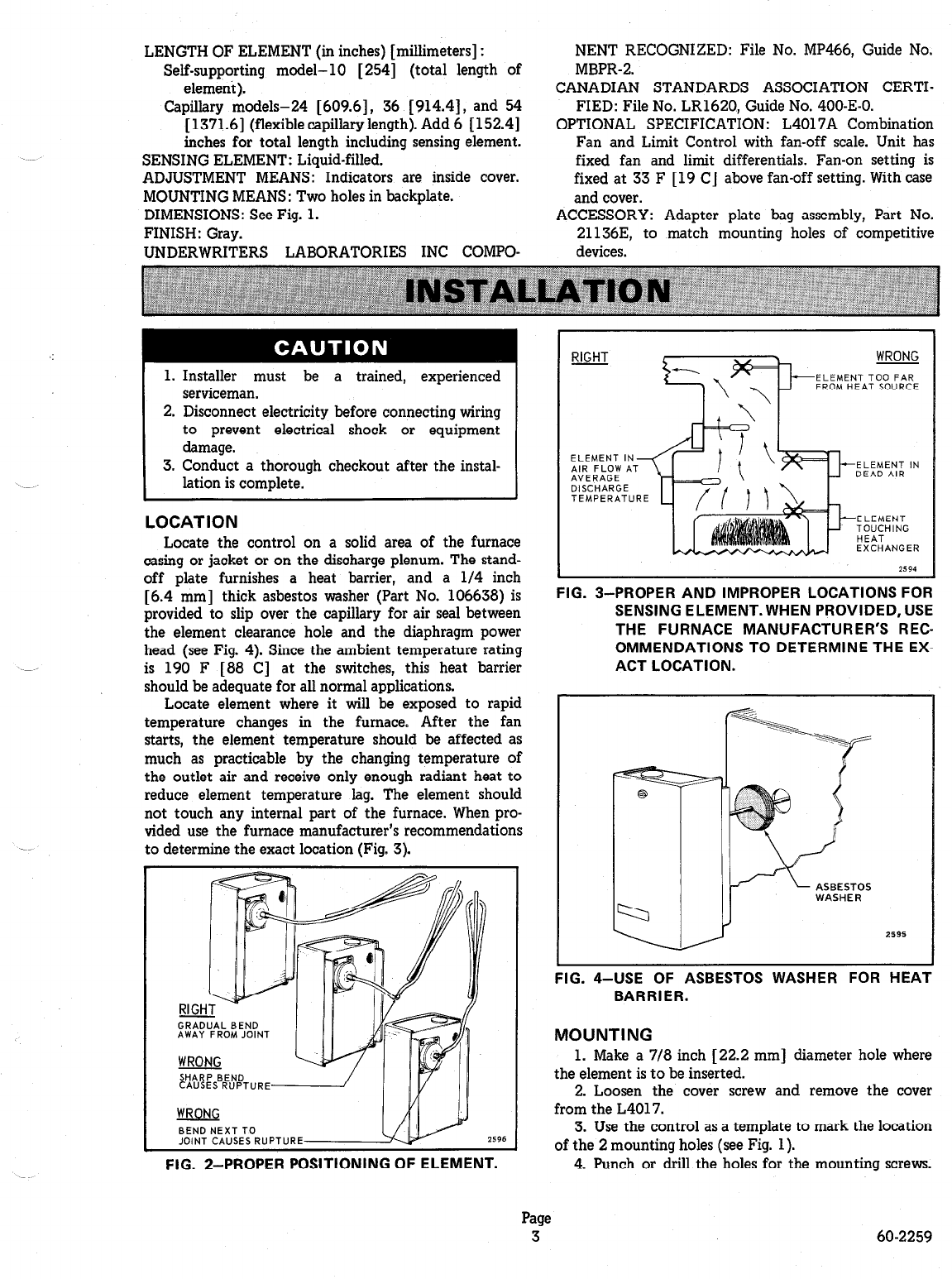

Locate element where it will be exposed to rapid

temperature changes in the furnace. After the fan

starts, the element temperature should be affected as

much as practicable by the changing temperature of

the outlet air and receive only enough radiant heat to

reduce element temperature lag. The element should

not touch any internal part of the furnace. When pro-

vided use the furnace manufacturer’s recommendations

to determine the exact location (Fig- 3).

SHARP BEND

CAUSES RUPTURE

WRONG

BENDNEXTTO

JOINT CAUSES RUPTURE

2596

FIG. 2-PROPER POSITIONING OF ELEMENT.

WRONG

ELEMENT TOO FAR

FROM HEAT SOURCE

ELEMENT I

AIR FLOW

ELEMENT IN

AVERAGE

DEAD AIR

DISCHARGE

TEMPERATURE

ELEMENT

‘,~~$“‘“”

EXCHANGER

FIG. 3-PROPER AND IMPROPER LOCATIONS FOR

SENSING ELEMENT. WHEN PROVIDED, USE

THE FURNACE MANUFACTURER’S REC-

OMMENDATIONS TO DETERMINE THE EX-

ACT LOCATION.

FIG. 4-USE OF ASBESTOS WASHER FOR HEAT

BARRIER.

MOUNTING

1. Make a 7/8 inch [ 22.2 mm] diameter hole where

the element is to be inserted.

2. Loosen the cover screw and remove the cover

from the L4017.

3. Use the control as a template to mark the location

of the 2 mounting holes (see Fig. 1).

4. Punch or drill the holes for the mounting screws.

Page

3

60-2259