– 4 –

Installation, Operation, and Care of

MODELS FD3-150, FD3-200, & FD3-300

FOOD WASTE DISPOSERS

SAVE THESE INSTRUCTIONS

GENERAL

The disposer features removable hardened steel components and reversible rotation with grinding in

both directions. The disposer is self-feeding, making it unnecessary to force the food waste into the

grinding mechanism.

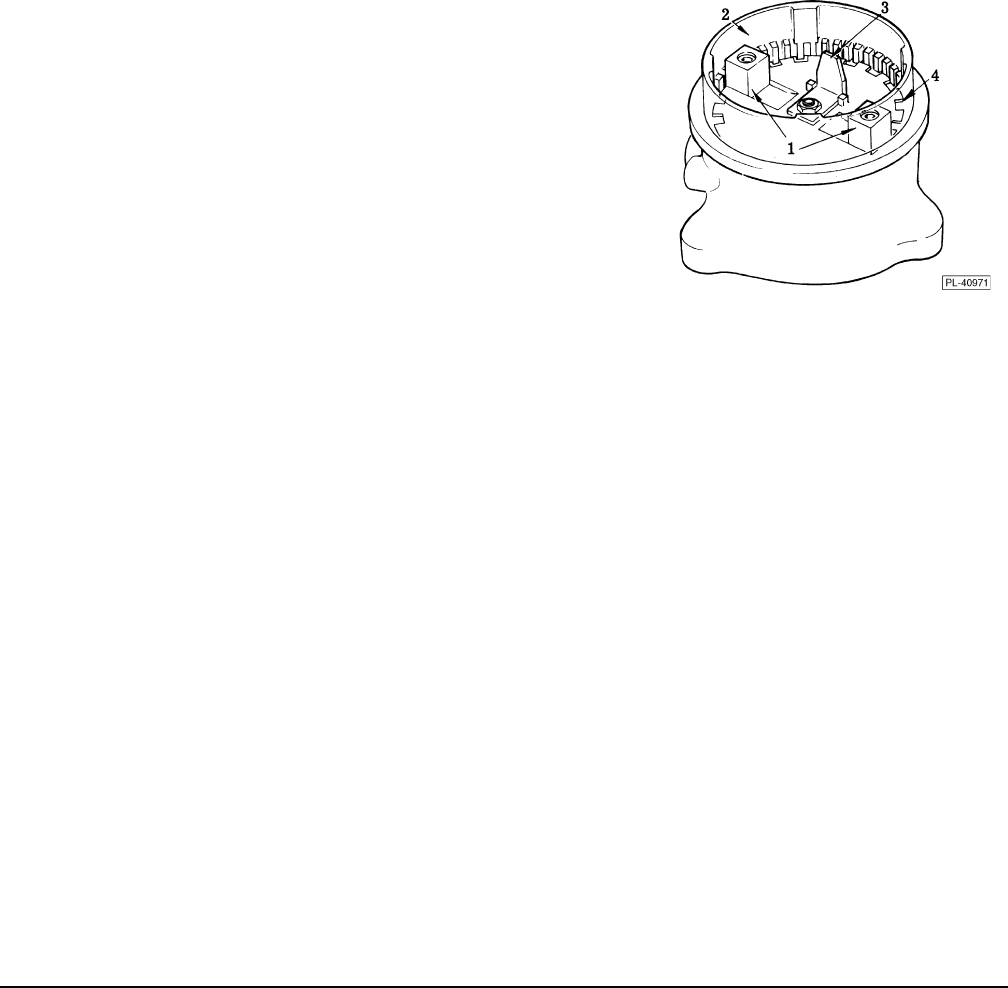

The FD3 Series disposers utilize hardened steel cutter blocks

(1, Fig. 1) mounted to a rotating flywheel (4, Fig. 1) and a

stationary shredder ring (2 Fig. 1) to grind food waste to a small

particle size for discharge through waste lines. With the motor

running and flushing water turned on, food waste is reduced to

grinding size by the rotating "hi-bulk" cutter (3, Fig. 1). Grinding

occurs as the food waste is forced against the shredder ring by

the cutter blocks and the centrifugal force due to rotation. The

flushing water aids the grinding action and discharges ground

food waste into the waste line.

Control groups and accessory groups are available to suit

each installation.

Fig. 1

INSTALLATION

Immediately after unpacking the disposer, check for possible shipping damage. If the disposer is found

to be damaged, save the packaging material and contact the carrier within 15 days of delivery.

Prior to installation, test the electrical service to make sure that it agrees with the specifications on the

disposer data plate.

Use legs and temporary blocking to support disposer during installation to avoid excessive stress at

welded or soldered cone to table connection.

ASSEMBLY

Use the following procedure to attach the disposer assembly to the cone (see Figs. 2 and 5).

Raise the disposer into position using the adjustable feet to bring the disposer into firm contact with

the cone flange. Do not place the weight of the disposer on the cone.

Turn each adjustable foot as required to complete height and level adjustments.

Assemble the clamp ring halves using the ten screws and tighten screws finger tight. Rotate disposer

to the desired position. Tighten the ten screws evenly to form a water tight joint.