INSTALLATION INSTRUCTIONS 3-phase R-22 Split System Heat Pump

506 01 5001 00 5

!

CAUTION

PRODUCT DAMAGE HAZARD

Failure to follow this caution may result in product

damage.

Indoor coil and outdoor unit must be listed as a

certified combination (match) in the ARI Unitary

Directory of Certified Products.

Indoor coil must have R-22 specific, hard shut-off

TXV refrigerant metering device.

When installing a hard shut-off TXV on an indoor coil,

follow the instructions provided with the new TXV.

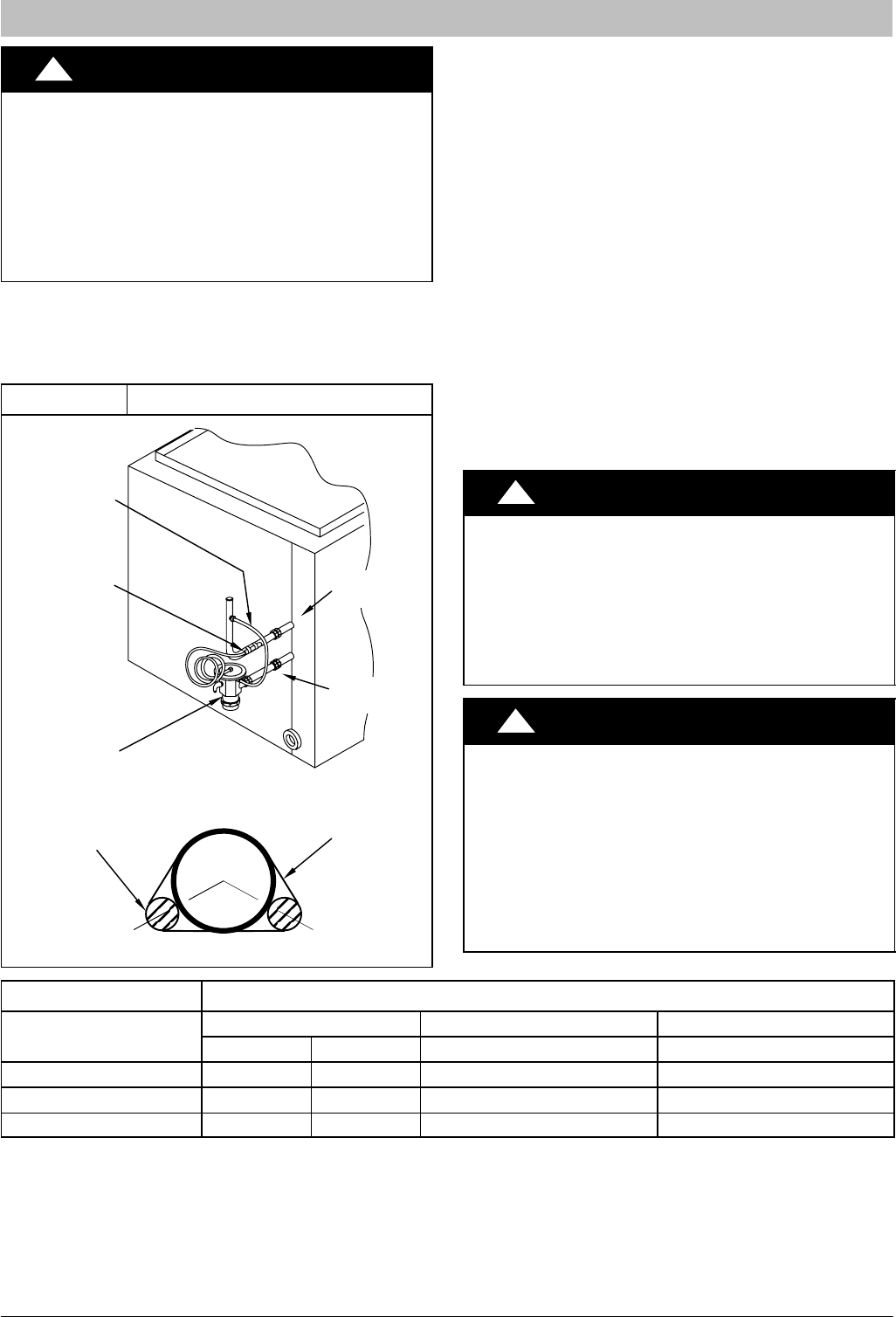

A typical hard shut-off TXV installation is shown in Figure

3.

Figure 3 Typical TXV Installation

HARD

SHUT-OFF

TXV

SENSING

BULB

EQUALIZER

TUBE

8 O'CLOCK 4 O'CLOCK

STRAP

SENSING BULB

(EITHER SIDE)

SUCTION

TUBE

INDOOR

COIL

SUCTION

TUBE

LIQUID

TUBE

B. REFRIGERANT LINE SETS

The refrigerant line set must be properly sized to assure

maximum efficiency and proper oil circulation. Select line

set tube diameters as specified in Figure 4.

NOTE: If the line set actual length is to exceed 80 feet, or

if there is more than 20 feet vertical separation between

outdoor and indoor units, refer to the Long Line

Application Guidline document for additional instructions.

NOTE: Line set actual length must not exceed 200 feet.

NOTE: A crankcase heater must be used when the

refrigerant line length exceeds 80 feet.

If it is necessary to add refrigerant line in the field, use

dehydrated or dry, sealed, deoxidized, copper

refrigeration tubing. Do not use copper water pipe.

Do not remove rubber plugs or caps from copper tubing

until connections are ready to be made.

Be extra careful when bending refrigeration tubing.

Tubing can “kink” easily, and if this occurs, the entire

length of tubing must be replaced.

!

WARNING

PERSONAL INJURY HAZARD

Failure to follow this warning could result in per‐

sonal injury and/or death.

Relieve pressure and recover all refrigerant before

servicing existing equipment, and before final unit

disposal. Use all service ports and open all flow-‐

control devices, including solenoid valves.

!

CAUTION

UNIT OPERATION HAZARD

Failure to follow this caution may result in improp‐

er product operation.

Do not leave system open to atmosphere any lon‐

ger than absolutely required for installation. Inter‐

nal system components - especially refrigerant

oils - are extremely susceptible to moisture con‐

tamination. Keep ends of tubing sealed during

installation until the last possible moment.

Figure 4 R-22 Line Set Tube Diameter (Liquid Tube Always a"” dia.)

Model Size

Service Valve Fittings Line Set < 80 feet long Line Set 80 - 200 feet long

Liquid Suction Suction Line Diameter Suction Line Diameter

36 (3 ton) a” w” w” d”

42 (32 ton), 48 (4 ton) a” d” d” !8”

60 (5 ton) a” d” !8” !8”

NOTE: If the line set actual length is to exceed 80 feet, or if there is more than 20 feet vertical separation

between outdoor and indoor units, refer to the Long Line Application Guideline document for additional instruc‐

tions.