Since 1967, Hellenbrand Water Conditioners, Inc. has provided water solutions to the water treatment industry in the

U.S. and around the world. We have developed a complete line of high quality products. An excellent example of this,

is the Hellenbrand TNT Series Conditioners.

TNT Series Conditioners use a anged top-mounted or optional side-mounted adapter, three-inch NPT inlet and

outlet solid brass control valve with a motor-driven, time-tested, hydraulically-balanced piston with a seal and spacer

concept to pilot service ow not dependent on water pressure. No diaphragms to rupture or false transfer. It will provide

up to 170 gpm hard water by-pass during regeneration, or you may have the optional “no hard water by-pass piston”

for twin or multiple systems. These high service ow rates, the simplied alternating and multiple lockout systems,

eliminate the need for diaphragms, solenoids and stagers. The ve cycle TNT controller is available with either downow

(co-current) or upow (counter-current) brining, with easy adjustable cycle times. The TNT Series offers you a choice

of mechanical or microprocessor controlled meter demand systems, with two-inch or three-inch meter turbines. All

systems are factory-wired and tested electrically to assure easy installation and correct operation.

Hellenbrand Means

Quality and Reliability

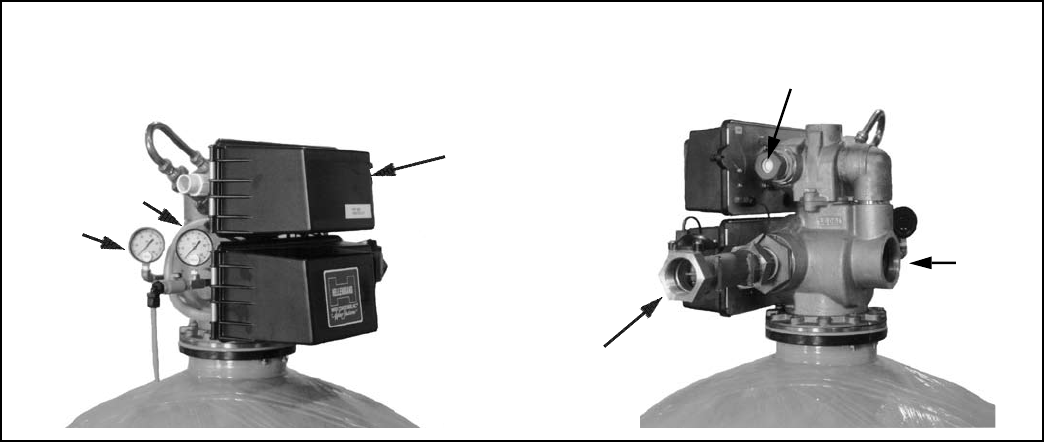

TNT Series Control Valve -Three Inch Inlet/Outlet

FRONT VIEW

BACK VIEW

or repositioning brine plugs for salt measurements.

8. Heavy-duty Drive Motor receives signal from timer

to efciently direct water ow during regeneration.

Piston shifts smoothly and quietly regardless of water

pressure.

9. Lower Heavy-duty Drive Motor receives signal from

upper drive motor to direct the service piston into

position. Piston shifts smoothly and quietly regardless

of water pressure.

10. TNT Series Timer provides fully automatic, depend-

able timing for regeneration. The Cycle Programmer

regulates all regeneration cycles which are easily

adjustable. For manual regeneration start, simply turn

the service indicator clockwise.

1. Stainless Steel Backplate will not rust or corrode.

2. Factory provided Drain Line Flow Control maintains

accurate backwash rates.

3. Three-Inch NPT Inlet & Outlet Connections.

4. Solid Brass Valve assures durability and long life.

5. Hydraulically-balanced Piston, Seal, and Spacers.

Lower service piston is available with or without hard

water by-pass. Non-sticking Teon-coated Piston al-

lows foreign particles to pass through without damag-

ing the unit.

6. Upper Piston pilots the regeneration steps of back-

wash, brine and slow rinse, fast rinse, and brine tank

rell.

7. Separate “Time-ll” Brining with accurate ow controls

allows automatic brine tank rell. Brine Tank Rell

Rates are easily adjustable on the cycle program-

mer. No need to worry about adjusting oat valves

Optional

2” Meter Outlet

Inlet

Optional Factory Installed Vacuum

Breaker

Controller

Inlet

Outlet

Optional Inlet & Outlet Pressure Gauges & Soft Water

Test Port