5.Time clock

This allows the HeatMaster

®

to be timed on and off and operates on

a 24 hour sequence. Around the outside of the clock there are a

number of white tabs, these allow 15 minute switching periods. To

set the time clock simply push outwards the number of tabs required

for ON period.

Remember: TAB IN = HeatMaster OFF

TAB OUT = HeatMaster ON

6.Temperature and pressure gauge

This gauge indicates both the temperature of the HeatMaster

®

and

the pressure within the primary circuit.

The temperature should not exceed 90°C - if it does, switch the

boiler off and check the thermostat setting. If the fault persists, call

an engineer.

The pressure should not fall below 1bar, if it does the please see the

'Heating System Pressure' paragraph later in this section.

7. Low primary water pressure indicator

If this indicator lights up, the primary circuit of the HeatMaster

®

requires topping up with water. Please see the 'Heating System

Pressure' paragraph later in this section.

Heating-system pressure

The heating circuit may require a top-up of water. The pressure

gauge, located beside the display, gives the pressure.

In the case of repeated fills, contact your installer.

The pressure of the primary circuit must be at least 1 bar and must

be regularly checked by the end user. If the pressure falls below

0.5 bar, the low-water-level pressure switch locks the appliance until

the pressure in the system returns to above 0.8 bar.

The HeatMaster

®

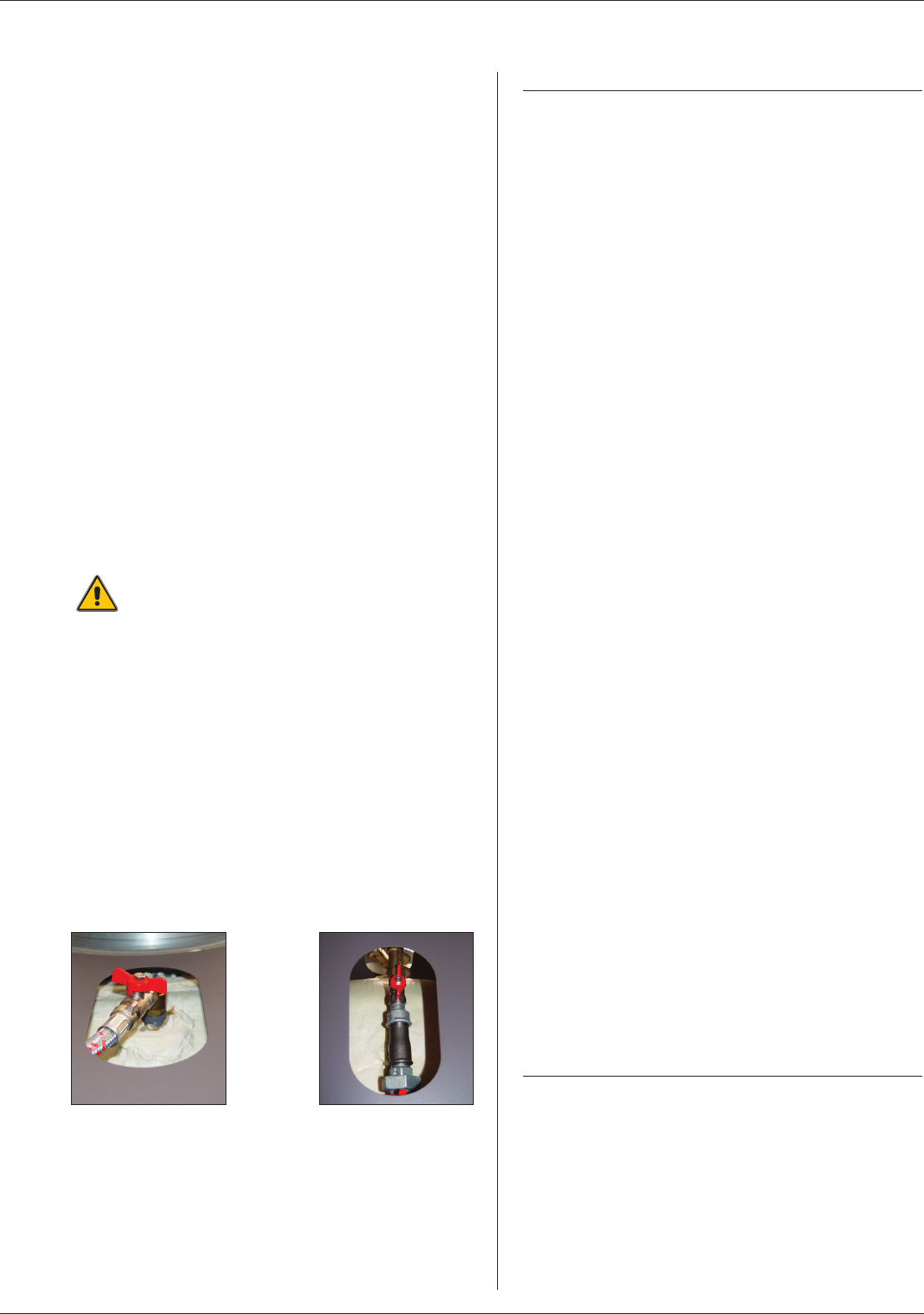

200 N / 200 F is fitted with a purpose-designed fill

set (see Fig. A and B). Always make sure that the appliance is

switched off when filling the system.

To do this, turn the On/Off switch on the left of the control panel to

Off.

For more information, please ask your installer when delivering the

system.

The appliance is fitted with a safety valve. If the system pressure

exceeds 3 bars, this valve opens and drains the water from the

system. In this case, contact your installer.

3

USER GUIDE DESCRIPTION

OPERATING PRINCIPLE

The HeatMaster

®

is a high performance, direct fired hot water

storage heater, which has indirect heat transfer due to its Tank-in-

Tank construction.

At the heart of the HeatMaster

®

is a stainless steel cylinder through

which the flue tubes pass. This is surrounded by a mild steel shell

containing the primary water (neutral fluid).The outer shell extends

down to the combustion chamber and even around the flue tubes.

The area of the heat transfer surface is therefore much greater than

that of standard direct fired water heaters.

A circulating pump fitted to the primary circuit moves the water

around the tank, heating it faster and maintaining an even

temperature across the primary jacket.

The burner, either gas or oil, fires onto the primary water which

indirectly heats the stainless steel cylinder containing the DHW. As

with all Tank-in-Tanks, this is corrugated over its full height and

suspended in the HeatMaster

®

by its hot and cold water

connections.

The cylinder expands and contracts during use and this, together

with the fact that cold water does not come into contact with the

intense heat of the burner flame, means that limescale buildup is

prevented.

This scale resistant feature, along with the corrosion resistance of

stainless steel, eliminates the need for sacrifical anodes.

The HeatMaster

®

has one very major advantage over other direct

fired water heaters - because it heats the DHW with a primary

circuit, this primary water can be used to provide central heating as

well.

By connecting two, three, four or more HeatMaster

®

together in a

module, most hot water and heating demands can be met.

Indeed, when used in conjunction with HR and Jumbo hot water

storage tanks the HeatMaster can supply even the largest hot water

requirement.

Standard equipment

The HeatMaster 200 has the following items as standard:

- On/off switch

- Summer/Winter switch

- Control thermostat (60 - 90°C)

- Thermal reset high-limit thermostat (95°C)

- Manual reset high-limit thermostat

- Hot water priority thermostat

- Primary circulating shunt pump

- Primary expansion vessels

- Primary safety valve

- Pressure and temperature gauge

- Drain valve

- Body completely insulated in rigid polyurethane foam

PACKING

The HeatMaster is delivered in separate packages.

• Package No. 1: Foam-insulated body, hydraulic accessories,

and control panel.

• Package No. 2: Chimney reducing pipe.

• Package No. 3: Wooden protective casing (jacket and

accessory).

• Package No. 4: “RIELLO” RG4S 396 T1 burner

(HM 200 F only).

Fig. A

(cover)

Fig. B

(rear panel)