15

BURNER FEATURES

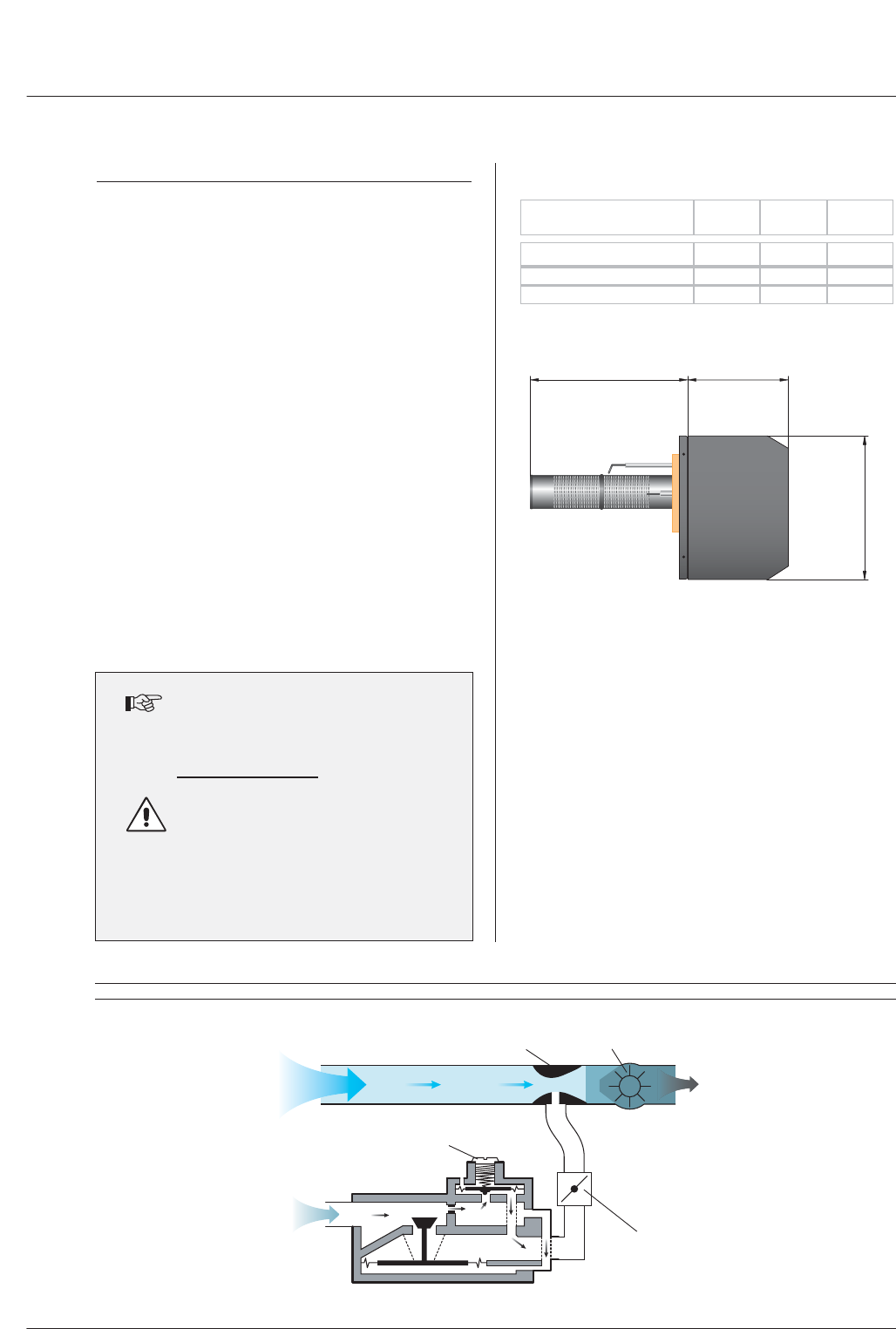

ACV BG 2000-S PREMIX GAS BURNERS

Description

The burner tube is coated with metal fibre (NIT) which, in addition to

its remarkable heat exchange capabilities, gives greater durability.

The main components are a venturi and one (model 60 and 70) or

two (model 100) gas valves, technology specially developed by

Honeywell for low Nox premix air/gas burners with automatic ignition

and ionisation flame detection.

The pressure at the gas valve outlet is equal to the air pressure in

the neck of the venturi, less the offset.The fan sucks combustion air

through the venturi, into which the gas inlet emerges.

As it passes through, the air produces a pressure differential in the

constriction of the venturi and sucks the gas into the venturi outlet.

A perfect mix of air and gas then passes through the fan to the

burner tube.

This design ensures very quiet and safe operation:

• If there is an air blockage, the pressure differential in the venturi

falls, the gas flow diminshes, the flame goes out and the gas

valve closes: the burner is in safety shutdown mode.

• If there is a blockage in the chimney outlet, the air flow diminishes,

and the same reactions as those described above cause the

burner to shut down in safety mode.

• The BG 2000-S burner fitted to the HeatMaster 60, 70 and 100

is controlled by a Honeywell module which controls burner

operating safety.

BG 2000-S burners are preset at the factory

for natural gas.

Conversion to propane:

Not applicable for Belgium.

Conversion kit included with burner comprising:

- Cap(s)

- Nameplate(s)

- Sticker with settings.

- Mounting instructions.

ACV BG 2000-S premix gas burners dimensions

Air

Gas flow

regulating screw

Offset regulation

screw

Gas

Air-gas mixture control system

248

342

342

228

248

248

375

375

375

BG 2000-S / 60

BG 2000-S / 70

BG 2000-S / 100

CBAType

AB

C

Air - gas

mixture

Venturi Fan