Page 3

R410a Application and Service Guide

Component Considerations for R410a

Compressor

Wall thickness has increased with the increase of operat-

ing pressures of R410a. The internal pressure relief valve

setting has been increased from 375-450 psig for R22 to

550-625 psig for R410a. Although the discharge pressure

is higher in R410a the discharge temperature should be

lower due its higher vapor heat capacity. Desuperheating

hot water generators must be designed around this lower

hot gas temperatures as well. High pressure switches will

now open at 600 psig ±10 psig and reset at 450 ±10 psig.

The compressor oil must be polyolester (POE) based.

Mineral oils should never be used. POE oils absorb

moisture VERY easily. For this reason any compressor

using POE oil should only be exposed to ambient air for

short periods of time during manufacture or service. See

the service section of this manual for more information.

Condenser/Evaporator Heat Exchangers

The heat exchangers must be designed to have a working

pressure above the 600 psig level. In some cases this can

mean a thicker wall.

Filter Driers

Liquid lter driers must have working pressure of no less

than 600 psig and be approved for use with R410a. A

100% molecular sieve with no activated Alumina is rec-

ommended for maximum moisture removal. It is always

required to install a new lter drier whenever the system

is opened.

Suction line lter driers should only be used after a burn

out and should be removed after an appropriate clean-up

time.

Thermostatic Expansion Valves

R410a metering devices are about 15% smaller than R22

devices. The selective charge used in the bulb must be

matched for R410a operation, therefore a TXV must be

designed for R410A use. METERING DEVICES for R22

and R410a are NOT INTERCHANGEABLE.

Refrigerant Tubing

There are no general changes to the tubing other than the

working pressure increase to 600 psig. Generally the

lower refrigerant ow rate of R410a versus R22 does not

result in any pipe diameter changes.

Polyolester Oils

POE oils are VERY hygroscopic. They readily

absorb moisture and hold it. For this reason POE oils

should be limited in their exposure to ambient air during

manufacture or service. The lubricant should be exposed

to ambient air for no more than 15 minutes. Always store

POE oil in glass or metal containers. Pumps are recom-

mended to move the oil from containers to the refrigera-

tion system. If the system is under a vacuum, break the

vacuum with refrigerant or dry nitrogen. It is never

recommended to break the vacuum with air. Liquid line

lter driers should be used to remove any moisture in the

system. Charging system may also contain a replaceable

lter drier for improved moisture removal. In summary:

• POE oil is hygroscopic and will readily absorb

moisture

• Never store POE oil in plastic containers. Always

use metal or glass

• Use a pump to transfer POE lubricants

• Use an approved POE lubricant. They arenʼt all

interchangeable

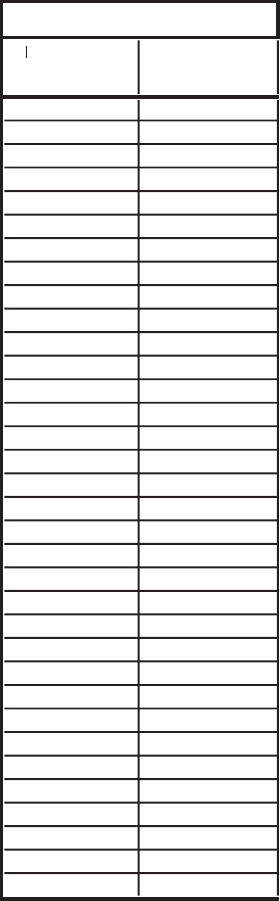

R410a

TemperatureT

emperature

T Pressure

°F psig

-15 31.3

-10 36.5

-5 42.2

0 48.4

5 55.1

10 62.4

15 70.2

20 78.5

25 87.5

30 97.2

35 107.5

40 118.5

45 130.2

50 142.7

55 156.0

60 170.1

65 185.1

70 201.0

75 271.8

80 235.6

85 254.5

90 274.3

95 295.3

100 317.4

105 340.6

110 365.1

115 390.9

120 418.0

125 446.5

130 476.5

135 508.0

140 541.2

145 576.0

150 612.8

Table 2. R410a Pressure/Temperature Chart