11

.

Effect of Extractor Fan

It is not permissable to use an air extraction device in the

same room as this appliance, unless additional ventilation

is provided to compensate the equivalent capacity.

Anything that may cause a negative pressure can cause

gases or fumes to be pulled into the living area.

Chimney and draft

The chimney is the most important element of a successful

stove operation. The chimney 'drives' the system by

producing the draft that draws in combustion air and

exhausts smoke and gases to outdoors.

When installing a new stove or upgrading an existing one,

give as much attention to the chimney as you do to the

appliance that it serves.

A glowing red hot stove or chimney connector indicates

excessive draft. The stoves failure to get hot, or long burn

times may indicate poor draft conditions.

Good draft in a cold chimney should be between 0.01"

and 0.1" of water column. ( your dealer may be able to

check this for you.

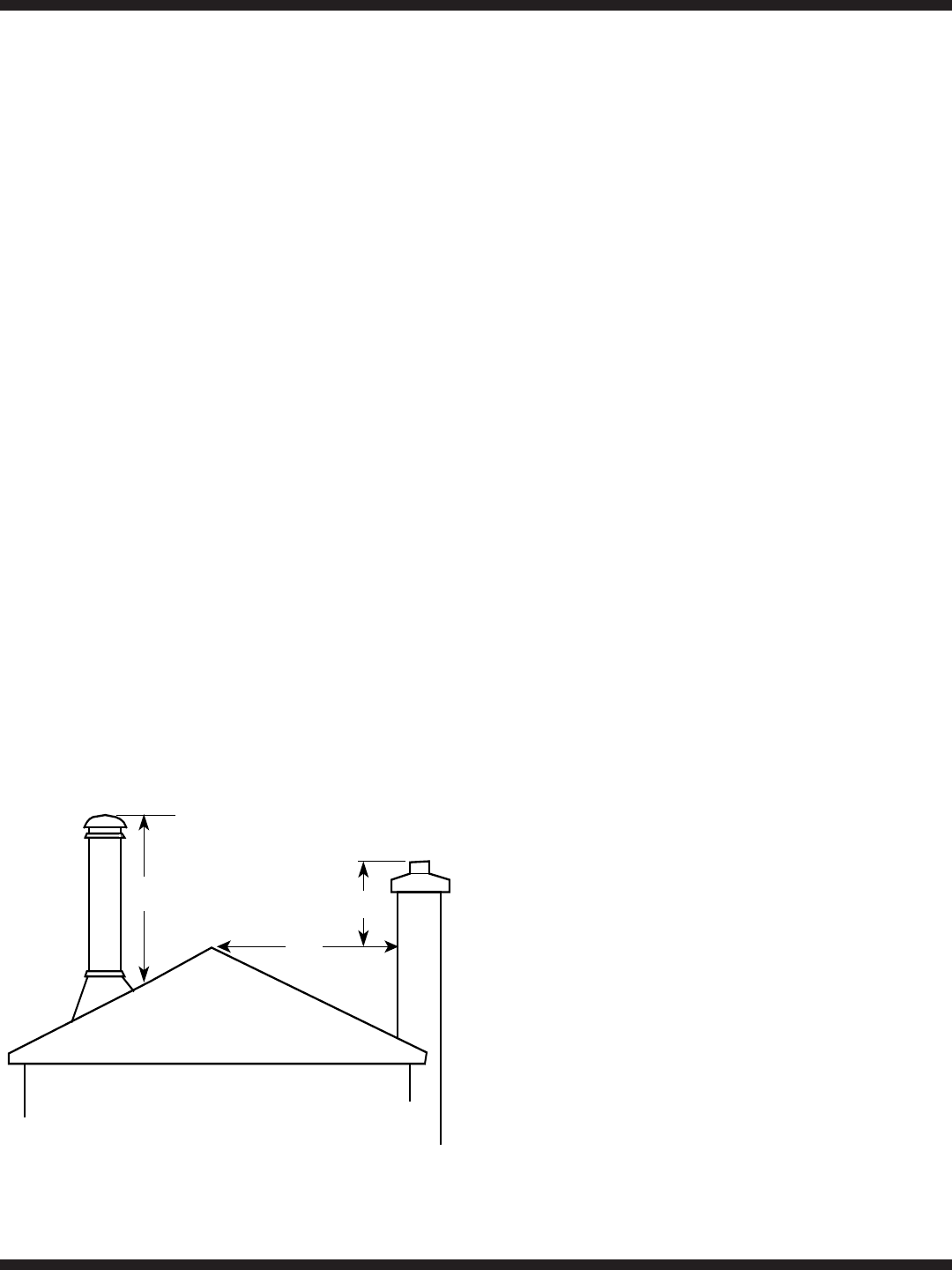

Recommended Chimney Clearances

The chimney must:

1) extend at least 14 ft. above the collar of the stove.

2) extend at least 3 ft. above the point where it passes

through the roof.

3) be at least 2 ft. above anything within a 10 ft.

radius of the top of the pipe.

Illustration showing minimum heights required,

depending on the locaton of chimney

24"

(600mm)

10'

(3 metres)

36"

(900 mm)

Floor Protection

When installing your woodstove on a combustible oor, a

non-combustible oor protector is required under the stove to

protect the oor from hot embers that may fall when reloading.

The oor pad must be a continuous, non combustible pad

(oor tile with grouting or sheet metal pad).A oor pad should

not be placed on top of a carpet.

Pad must extend 21"(534mm) in front of the stove in Canada

and 18" (458mm) in front of stove in US.

Pad must extend 8"(203mm) to the sides and back of the

stove.

Pad must extend fully to the wall if using side and back

Chimney Maintanence

Chimneys serving woodburning appliances must be checked

regularly for creosote build-up.Until you are familiar with the

rate of creosote build-up in the system, check it often - every

couple of weeks.

Creosote may be in the form of dry, aky deposits clinging to

the liner of a shiny, glazed coating that resembles black paint.

Glazed creosote is the most dangerous kind and indicates

that one or a combination of the following conditions exist.

1) cold liner

2) smouldering res

3) wet wood

Glazed creosote should never exceed 1/8" (3mm) thickness.

Dry aky cresote should never exceed 1/4" (6mm) thickness

before it is removed.

Pad extension must be fabricated from non-combustible ma-

terials: 1/2” (13 mm) thick minimum with thermal conductivity

factor “K” of 0.43 or lower (units of K = btu/ft/h/F/in).

To determine thickness of equivalent material required use

formula: (“K” x 0.5) / 0.43 = thickness required (“K” value can

be obtained from manufacturer of oor material).