AB094FAAHA

AB124FAAHA

AB184FAAHA

AB244FAAHA

AB424FAAHA

AB484FAAHA

AU52LFIAHA

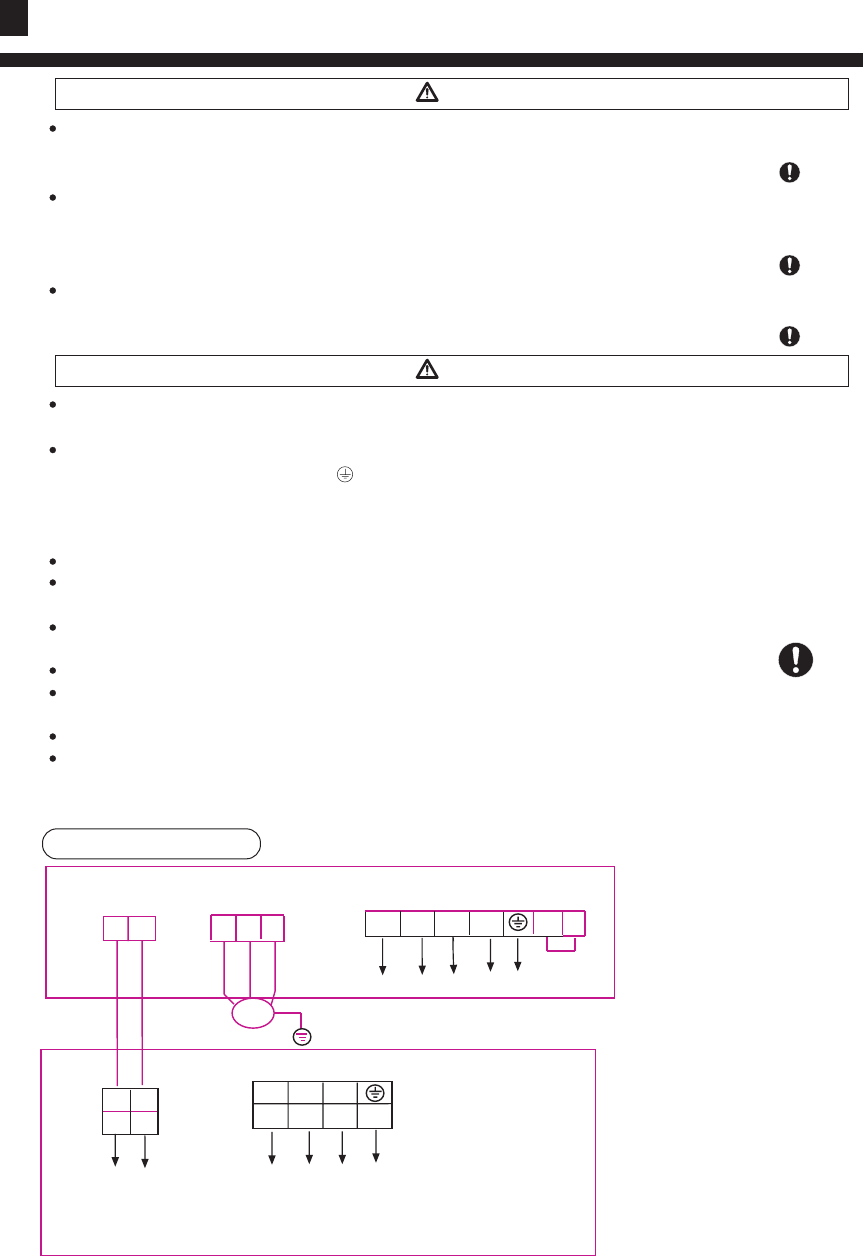

Electrical Wiring

C1

C2

R

R

C1

C2

R

ST

N

Lm1

Lm2

Note:

1:L(black)

2:N(white)

3:C(red)----It's no use for Builtin EEV Type on the indoor unit .

U

V

W

CM

Compressor

26

W B R

1 2 3

POWER SUPPLY:

3N~,380-400V,50 /60Hz

INDOOR UNIT TERMINAL BLOCK

OUTDOOR UNIT TERMINAL BLOCK

Y/G

POWER SUPPLY:1PH,220-230V,50/60Hz

communication

communication

Electrical construction should be made with specific mains circuit by the qualified personnel according

to the installation instruction. Electric shock and fire may be caused if the capacity of power supply

is not sufficient.

During arranging the wiring layout, specified cables should be used as the mains line, which accords

with the local regulations on wiring. Connecting and fastening should be performed reliably to avoid

the external force of cables from transmitting to the terminals. Improper connection or fastness may

lead to burning or fire accidents.

There must be the ground connection according to the criterion. Unreliable grounding may cause

electrical shocks. Do not connect the grounding line to the gas pipe, water pipe, lightening rod and

telephone line.

Warning

Attention

Only copper wire can be used. Breaker for electric leakage should be provided, or electric shock may

occur.

The wiring of the mains line is of Y type. The power plug L should be connected to the live wire and

plug N connected to null wire while should be connected to the ground wire. For the type with auxiliary

electrically heating function, the live wire and the null wire should not be misconnected, or the surface

of electrical heating body will be electrified. If the power line is damaged, replace it by the professional

personnel of the manufacturer or service center.

The power line of indoor units should be arranged according to the installation instruction of indoor units.

The electrical wiring should be out of contact with the high-temperature sections of tubing as to avoid

melting the insulating layer of cables, which may cause accidents.

After connected to the terminal tier, the tubing should be curved into be a U-type elbow and fastened

with the pressing clip.

Controller wiring and refrigerant tubing can be arranged and fixed together.

The machine cant be powered on before electrical operation. Maintenance should be done while the

power is shut down.

Seal the thread hole with heat insulating materials to avoid condensation.

Signal line and power line are separately independent, which cant share one line. [Note: the power line,

connecting line, signal line are provided by users. Parameters are shown as below: 3×(1.0-1.5) mm

2

;

parameters for signal line: 2×(0.75-1.25)mm

2

( shielded line)]

Supply Wiring Drawing