– 10 –

up of lime in the T&P valve, there are two recommendations:

1. Install a pressure relief (only) valve in the cold water

supply line. Make sure that the discharge of this valve is

directed to a drain and it is protected from freezing.

or:

2. Install an expansion tank on the cold water supply line.

For every 50 gallons of stored water, the expansion tank

must have a minimum capacity of 1.5 gallons.

Vacuum Relief Valves

Water heaters shall be protected against loss of water from

siphoning due to loss of supply pressure by a vacuum relief

valve installed in the cold water supply line at a level above

the top of the water heater. Where heating equipment has a

bottom supply, the cold water supply piping shall be carried

above the top of the heater before being routed to the sup-

ply connection and have a vacuum relief valve installed in it

at a level above the top of the storage tank. The vacuum

relief valve shall be in compliance with the standard ANSI

Z21.22 (latest issue).

Installation Of The Aquastat

(Temperature Control)

This heater operates automatically under the control of the

aquastat, which responds to the demand of hot water.

Depending on the model, the aquastat, well and wiring is

either installed on the heater, or included in the carton con-

taining the burner. If the installation of the aquastat is

required, proceed as follows:

1. Locate the aquastat well opening in the front of the

heater.

2. Apply a good grade of pipe joint compound to the

threads on the well.

3. Install the well in the tank opening, tighten firmly to

ensure there are no leaks.

4. Insert the sensing bulb of the aquastat into the well and

secure the aquastat to the well using the screw provid-

ed.

5. Wire the control to the burner as shown in the wiring dia-

grams (Figures 9, 10 & 11).

Electrical Supply Connections

General wiring requirements:

Electric shock hazard. Can cause severe personal injury or

death if power source, including service switch on heater, is

not disconnected before installing or servicing. Installations

must comply with the latest edition these codes:

• “Canadian Electrical Code Part 1 (CSA C22.1)”

(Canada).

• “National Electrical Code, ANSI/NFPA 70”, (USA).

• Any additional local, provincial, national or state codes.

Wiring must be N.E.C. Class 1. If original wire supplied with

heater must be replaced, type 105°C wire or equivalent

must be used. Supply wiring to heater and additional control

wiring must be 14 ga. or heavier. Provide an electrical

ground at heater as required by codes.

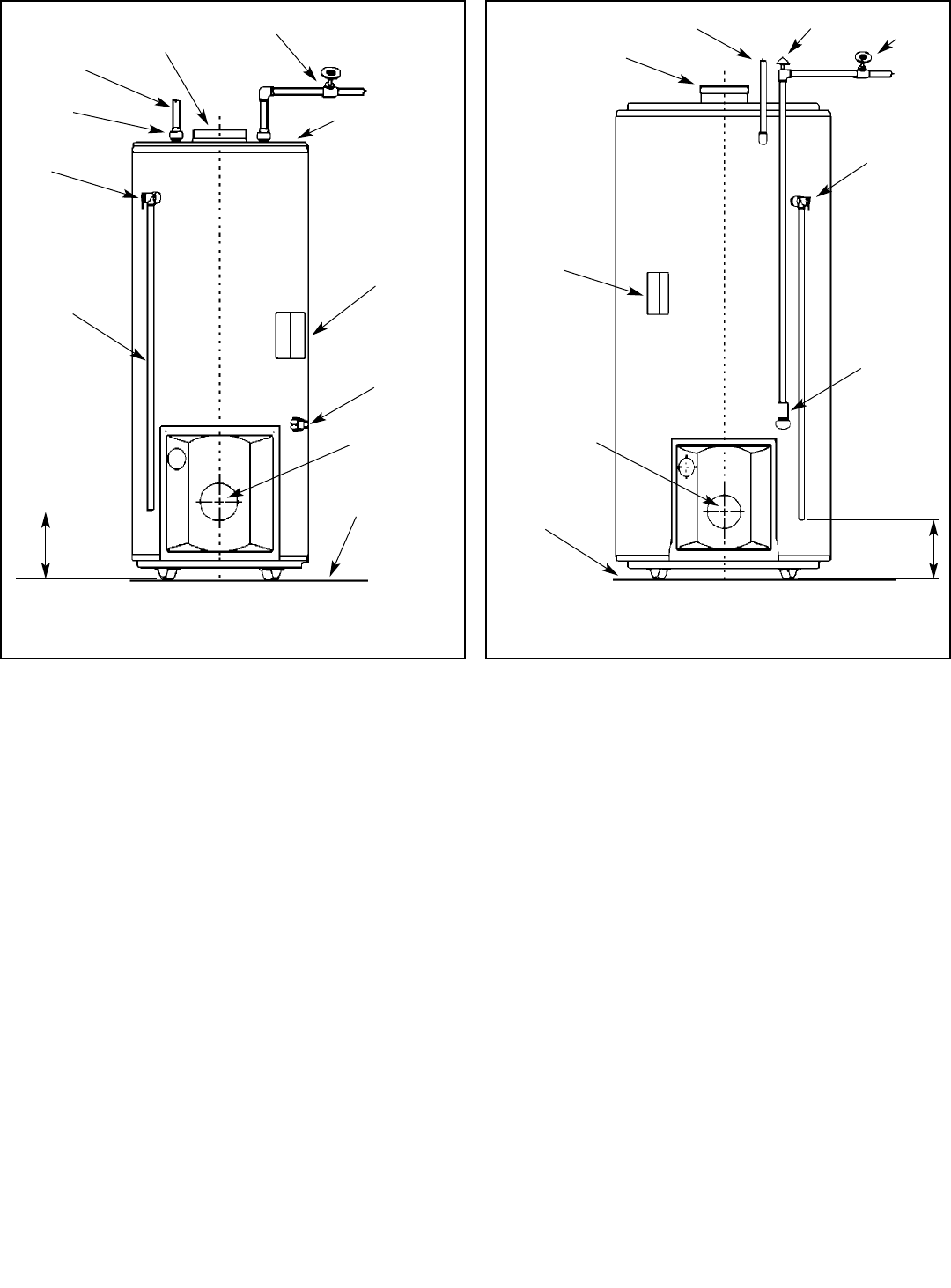

COLD WATER

SHUT-OFF

AQUASTAT

TEMPERATURE

CONTROL

T&P VALVE

COLD INLET AND

DRAIN VALVE

COMBINATION

HOT WATER

OUTLET

Figure 8 PLUMBING CONNECTIONS

(CENTER/REAR FLUE)

150 TO

305mm

6 TO 12”

FLUE COLLAR

CAPPED FOR REAR

FLUE USE (OPTIONAL)

VACUUM BREAKER

CENTER OF

BLAST TUBE

NON-COMBUSTIBLE

FLOOR

COLD WATER

SHUT-OFF

AQUASTAT

TEMPERATURE

CONTROL

T&P VALVE

DRIP TUBE

DRAIN

VALVE

HOT WATER

OUTLET

Figure 7 PLUMBING CONNECTIONS

(CENTER FLUE)

150 TO

305mm

6 TO 12”

CENTER OF

BLAST TUBE

NON-COMBUSTIBLE

FLOOR

TOP

NIPPLE

BREECH

CONNECTION