44

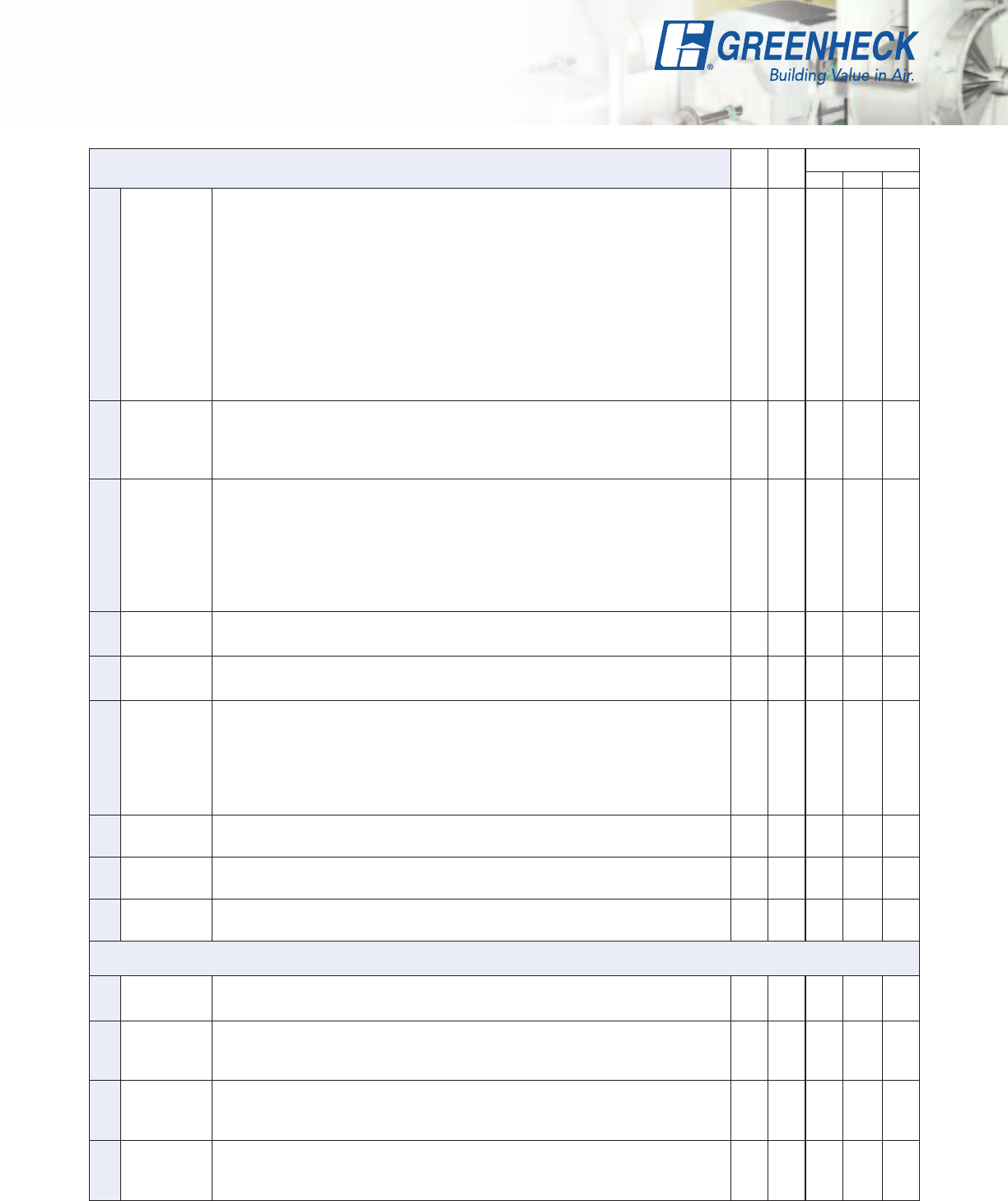

Standard Construction Features

Standard Construction Features

SFD SFB

SWB

100 200 300

1 Wheel

SFD and SFB fans have forward-curved centrifugal wheels constructed of

die formed steel with blades securely riveted to a steel backplate and rim.

Each wheel is statically and dynamically balanced to precise tolerances.

SWB Series 100 and 200 through size 210 have backward-inclined non-

overloading centrifugal wheels constructed of aluminum. Series 200, sizes

212 and larger and Series 300 wheels are constructed of steel or aluminum.

Backward-inclined wheels are made of a heavy-gauge material with single-

thickness blades securely riveted or welded to a heavy-gauge backplate

and wheel cone. SWB Series 300 fans are available with aluminum airfoil

wheels. Each wheel is statically and dynamically balanced to precise

tolerances.

Forward Curved

Forward Curved

Backward Inclined

Backward Inclined

Backward Inclined or Airfoil

2 Finish

All structural steel parts are phosphate treated and coated with

Greenheck’s Permatector™ for a long lasting finish. Galvanized

construction remains unpainted.

•See housing and drive frame information for specific material and coating.

— — — — —

3 Housing

SFD and SWB Series 100 housings are constructed of galvanized steel.

SFB and SWB Series 200 and 300 housings are constructed of steel

and coated with Permatector™. Both are available in clockwise or

counterclockwise rotation and are field rotatable to the eight standard

discharge positions. Housing sides are bonded to the fan scroll with an

airtight lock seam. Fully welded scrolls are available on SFB and SWB

Series 200 and 300 models.

Galvanized

Painted Steel

Galvanized

Painted Steel

or Aluminum

Painted Steel

4 Housing

Supports

Housing supports are constructed of heavy gauge-steel with formed

flanges for extra strength.

5 Mounting

Holes

Base rails have prepunched mounting holes which allow for easy

installation.

6 Drive

Frame

Series 100 and 200 drive frames are constructed of rugged, welded

and coated steel members (Series 300 drive frames are constructed of

reinforced heavy gauge galvanized steel) supporting the shaft and bearings

to provide rigid reinforcement for the housing. SFD drive frames are

constructed of galvanized steel, bolted and available in arrangement 4.

SFB and SWB are arrangement 10.

Galvanized

Painted Steel

Painted Steel

Painted Steel

Galvanized

7 Fasteners

Corrosion-resistant fasteners are used to secure unit base and blower

scroll assembly.

8 Motor

Heavy-duty ball bearing motors are carefully matched to the fan load. Open

drip proof, totally enclosed and explosion resistant enclosures are available.

9 Inlet Cone

Streamlined inlet cone design provides for low turbulence air intake,

reducing intake losses and sound levels.

Belt Drive Only Features

10 Motor

Plate

A pivoting motor plate with adjusting screws make belt tensioning a quick

and easy operation.

11 Drive

Assembly

Machined, cast iron pulleys are factory set to the required RPM and are

adjustable for final system balancing for applications with 10 hp or less

motors. Sized for a minimum of 150% of driven horsepower.

12 Fan Shaft

Precision turned, ground and polished solid steel shafts are sized so the

first critical speed is at least 25% over the maximum operating speed.

Stainless steel shafts are available on SWB Series 200 and 300 fans.

13 Bearings

Heavy-duty, self-aligning pillow block ball bearings are selected for a

minimum L

10

life in excess of 100,000 hours (L

50

average life of 500,000

hours) at maximum cataloged operating conditions.